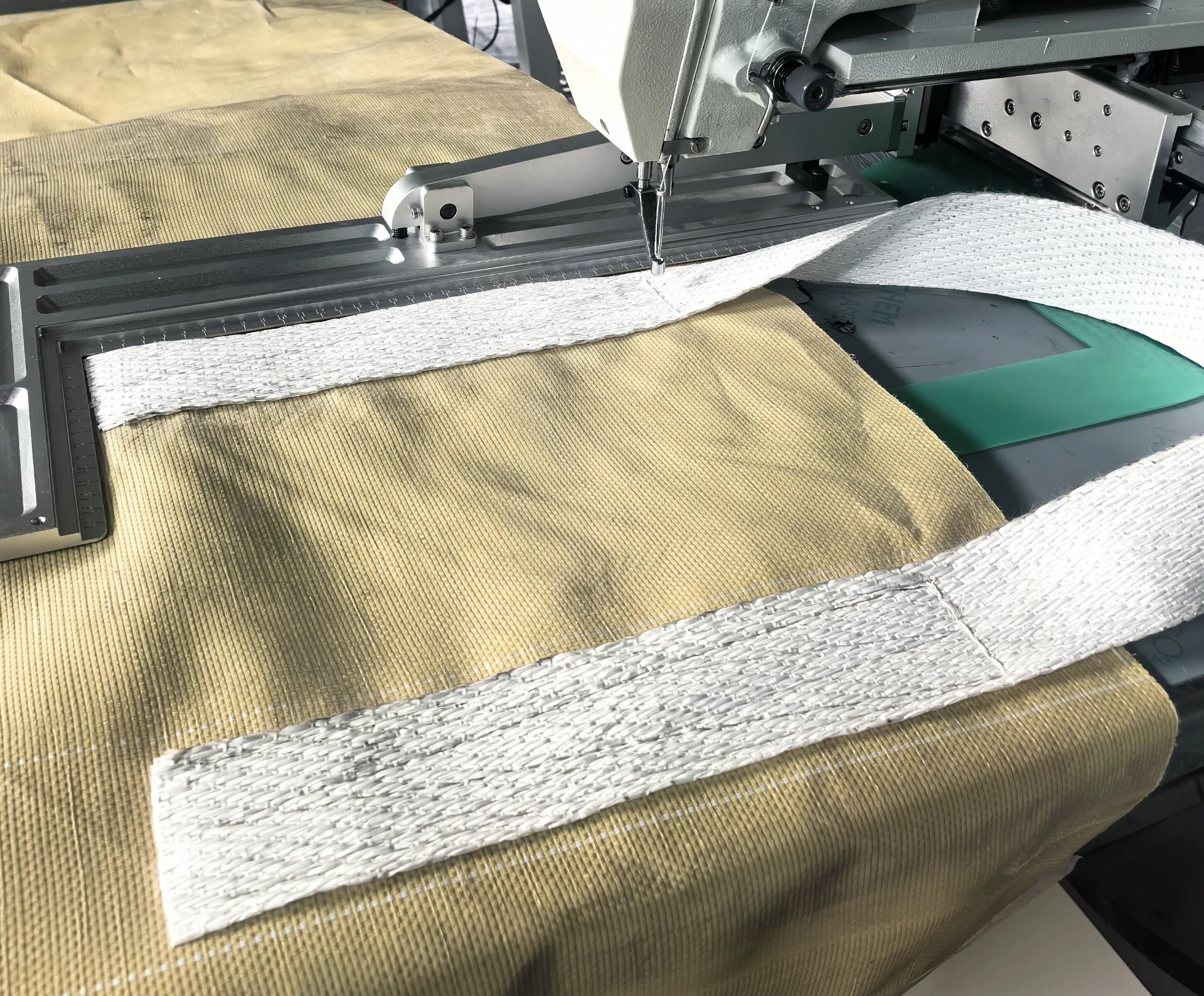

automatic woven sack cutting and stitching machine

Automatic Woven Sack Cutting and Stitching Machine Revolutionizing the Packaging Industry

The rapid evolution of manufacturing technologies has significantly impacted various sectors, particularly the packaging industry. Among the advanced machinery transforming this field is the Automatic Woven Sack Cutting and Stitching Machine. This innovative equipment enhances production efficiency, reduces labor costs, and improves product quality in packaging woven sacks for an array of industries, including agriculture, construction, and food processing.

Understanding Woven Sacks

Woven sacks, often crafted from polypropylene or HDPE (high-density polyethylene), are essential for packaging products such as grains, animal feed, fertilizers, and construction materials. Their durability, lightweight nature, and resistance to moisture make them ideal for the safe storage and transportation of numerous goods. However, the traditional methods of cutting and stitching these sacks have been labor-intensive, time-consuming, and prone to errors, leading to fluctuations in the quality of final products.

The Emergence of Automatic Machines

The advent of automated cutting and stitching machines has addressed many challenges associated with manual processes. These machines are designed to streamline operations from cutting the fabric to stitching the sacks, significantly reducing the production time. An automatic woven sack cutting and stitching machine typically consists of several components, including a cutting unit, a stitching unit, and an automatic control system, all working in unison to optimize efficiency.

Key Features of Automatic Woven Sack Machines

1. High-Speed Operation One of the foremost advantages of these machines is their speed. Capable of producing hundreds or even thousands of sacks per hour, they drastically increase output compared to traditional methods.

2. Precision Cutting and Stitching Automatic machines are equipped with advanced cutting technologies that ensure precise dimensions, minimizing waste and enhancing product quality. The stitching mechanisms also guarantee strong seams, preventing breakage during handling and transportation.

3. User-Friendly Interfaces Modern machines come with intuitive control panels that allow operators to quickly set parameters for different sack sizes and materials. This adaptability is crucial for companies that cater to diverse client needs.

automatic woven sack cutting and stitching machine

4. Reduced Labor Costs By automating the cutting and stitching processes, businesses can significantly cut down on labor costs. Fewer workers are needed to manage the production line, and those involved can focus on more strategic tasks, such as quality control and maintenance.

5. Enhanced Safety Standards Automated machines are designed with safety features, reducing the risk of workplace accidents associated with manual cutting and stitching. This is essential for maintaining a safe working environment.

Applications Across Industries

The versatility of automatic woven sack cutting and stitching machines makes them increasingly popular across various sectors

- Agriculture In agriculture, these machines are used to pack fertilizers, seeds, and grains. The durability of woven sacks ensures that agricultural products can be stored and transported without damage.

- Construction Construction materials such as sand, cement, and other aggregates are often packaged in woven sacks. The automated machines help streamline the packaging process, ensuring that supplies are readily available for construction projects.

- Food Processing Woven sacks are also utilized in the food industry for packaging sugar, rice, and flour. The automatic machines guarantee hygiene and quality standards are met, essential for food safety.

Conclusion

In conclusion, the Automatic Woven Sack Cutting and Stitching Machine represents a significant advancement in the packaging industry. By enhancing efficiency, precision, and cost-effectiveness, these machines not only improve production capabilities but also contribute to better quality products. As industries continue to evolve and demand for packaging solutions rises, the role of automation will undoubtedly become more prominent, paving the way for innovations that can further streamline processes and enhance product quality. Companies looking to stay competitive in today’s fast-paced market should consider investing in this sophisticated equipment to keep up with the demands of production and quality standards in the packaging sector.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025