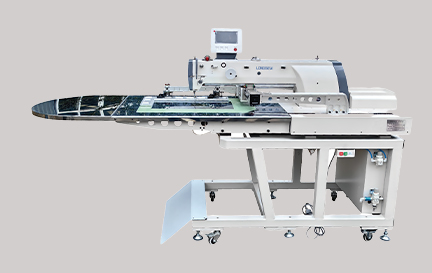

Advanced Automatic Single Needle Sewing Machine for Efficient and Precise Stitching

The Evolution and Benefits of Automatic Single Needle Sewing Machines

Sewing has been an essential part of human civilization, facilitating the creation and mending of garments and various textiles. With technological advancements, sewing machines have transformed from manual cranks to sophisticated automatic systems. Among these innovations, the automatic single needle sewing machine stands out as a pivotal tool in modern textile manufacturing.

Understanding the Technology

At its core, the automatic single needle sewing machine is designed for precision stitching using a single needle. Unlike multi-needle machines that can perform various stitching patterns simultaneously, the single needle model excels in tasks requiring high accuracy and consistency. This design is particularly advantageous for sewing straight seams and topstitching on lighter fabrics, which are prevalent in the garment industry.

Equipped with advanced features, automatic single needle sewing machines can operate without the constant intervention of an operator. These machines often include automatic thread cutting, programmable stitch lengths, and the ability to adjust tension and feed rates. Such features enhance productivity, reduce waste, and ensure a high-quality finish, making them indispensable for manufacturers looking to optimize efficiency.

The Historical Context

The inception of the sewing machine dates back to the early 19th century, revolutionizing the way fabrics were stitched together. However, it wasn’t until the introduction of automatic machines that the industry fully harnessed the potential of mechanized sewing. The automatic single needle sewing machine saw significant advancements in the mid-20th century, when electronic controls and later computerization were introduced, allowing for more complex designs and faster production times.

As the global demand for textiles surged, particularly in the fashion industry, manufacturers sought reliable and efficient machines to streamline their processes, giving rise to the widespread adoption of automatic single needle sewing machines.

Benefits Over Traditional Methods

automatic single needle sewing machine

One of the most considerable advantages of the automatic single needle sewing machine is its efficiency. Traditionally, sewing was a tedious manual process requiring significant human labor. Automatic machines can operate at higher speeds, reducing the time taken to complete tasks. For example, an experienced operator can stitch a seam by hand in a few minutes, whereas an automatic machine can do the same in seconds.

Moreover, the consistency of an automatic machine is unmatched. Human error, such as uneven stitches or incorrect tension settings, is virtually eliminated. This results in uniform products that meet the high standards expected in the modern market. For manufacturers, this consistency contributes to reduced rework and waste, directly impacting profitability.

Applications in Various Industries

The versatility of automatic single needle sewing machines allows them to be used across numerous industries. In the fashion industry, they play a crucial role in garment construction, from sampling to mass production. In the automotive industry, these machines are utilized for upholstery, ensuring durable and aesthetically pleasing interiors. Additionally, the home sewing market has also seen a rise in the popularity of automatic single needle machines, empowered by features like programmable stitches and user-friendly interfaces.

Challenges and Future Prospects

Despite their numerous advantages, automatic single needle sewing machines do face challenges. Initial investment costs can be high, particularly for small businesses. Additionally, the training required to operate these machines effectively can deter some potential users.

Yet, the future appears bright for these machines. With ongoing advancements in technology, the integration of artificial intelligence and IoT is likely to enhance their functionality further. Features such as predictive maintenance, where machines can alert operators to potential issues before they arise, could minimize downtime and extend machine lifespans.

Conclusion

The automatic single needle sewing machine represents a significant leap forward in textile manufacturing. By combining speed, precision, and efficiency, it has reshaped the landscape of sewing, allowing industries to meet the ever-growing consumer demand. As technology evolves, these machines will no doubt continue to adapt, reinforcing their essential role in both manufacturing and home sewing alike. The journey of sewing machines, from simple mechanical devices to complex automated systems, embodies the spirit of innovation—a testament to how far we have come and a glimpse into a future rich with possibilities.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025