automatic industrial sewing machine price

The Price of Automatic Industrial Sewing Machines Factors and Considerations

Automatic industrial sewing machines play an essential role in the textile and garment industries, streamlining production and enhancing efficiency. These machines are engineered to perform with precision, capable of handling a variety of fabrics and intricate designs. As businesses look to invest in these advanced tools, understanding their prices and the factors that influence them is crucial.

Initial Investment Costs

The price of automatic industrial sewing machines can vary significantly, ranging from a few thousand to tens of thousands of dollars. The most basic models might start around $2,000, while higher-end machines equipped with specialized features can exceed $100,000. This initial investment reflects the technology and capabilities built into these machines, including automated threading, stitch patterns, and even computerized control systems.

Types of Machines

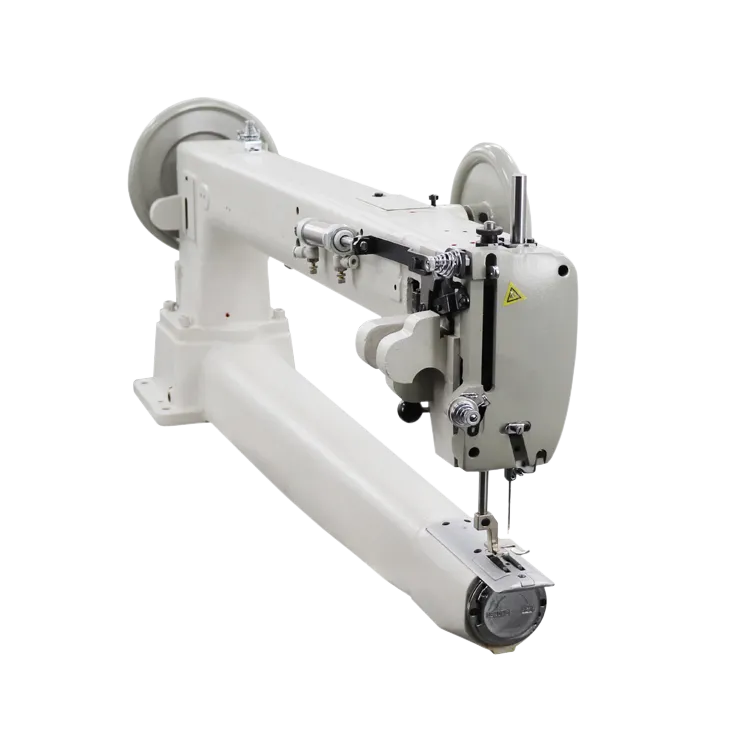

One of the primary factors affecting the price is the type of automatic sewing machine. For instance, flat-bed, cylinder-bed, and overlock sewing machines serve different purposes in garment manufacturing. Flat-bed machines are common for general stitching tasks, while cylinder-bed machines are useful for cylindrical items like sleeves and cuffs. Automated embroidery machines, on the other hand, have higher price tags due to their specialized functions and advanced capabilities. Buyers should evaluate their specific needs to find a machine that fits their production requirements.

Brand and Quality

automatic industrial sewing machine price

The brand also plays a significant role in pricing. Established manufacturers with a reputation for quality and durability typically charge more for their machines. Brands like Juki, Brother, and Pfaff are known for their innovative features and lasting performance, making them popular choices among industry professionals. While cheaper alternatives may appear attractive, potential buyers should consider long-term reliability and maintenance costs.

Features and Technology

The features integrated into the machines can dramatically affect their prices. Machines equipped with digital interfaces, programmable stitch patterns, automatic thread cutters, and built-in sensors for detecting material types often come at a premium. These features can drastically improve efficiency and reduce human error, ultimately justifying the investment.

Maintenance and Support

Another cost consideration is maintenance and support. High-quality machines often come with warranties and access to customer support services, which can mitigate future expenses. Conversely, lower-priced machines may lack robust support, potentially leading to higher costs for repairs or replacements.

Conclusion

In conclusion, the price of automatic industrial sewing machines is influenced by several factors, including type, brand, features, and support. Businesses looking to invest in these machines must weigh their production needs against the initial investment and long-term costs. By doing so, they can ensure that they select a machine that not only fits their budget but also enhances their operational efficiency in the competitive textile market.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025