3 needle chain stitch machine

The 3% Needle Chain Stitch Machine Revolutionizing Textile Manufacturing

In the ever-evolving world of textile manufacturing, efficiency and precision are paramount. Among the innovative tools designed to enhance these aspects is the 3% Needle Chain Stitch Machine. This machine not only streamlines the production process but also raises the quality standard in garment and textile manufacturing, making it an invaluable asset for manufacturers across the globe.

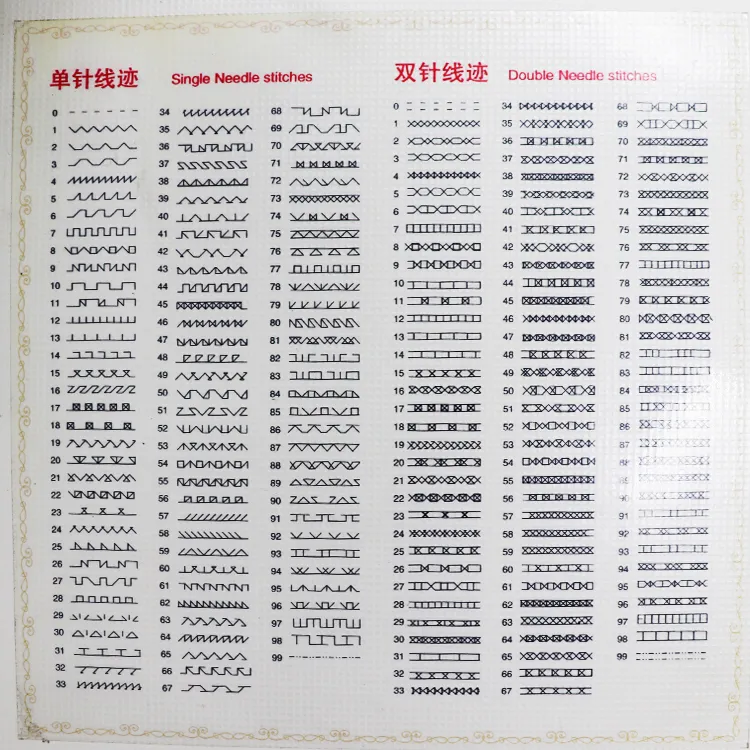

The 3% Needle Chain Stitch Machine is a specialized sewing machine that utilizes multiple needles—specifically three—in a chain stitching configuration. This design is particularly beneficial for producing durable and high-quality seams that are often required in industrial applications. The primary advantage of using three needles is that it allows the machine to create a more intricate and robust stitch pattern compared to traditional single-needle machines. This results in stitches that are not only aesthetically pleasing but also remarkably strong, which is essential for heavy-duty fabrics.

Advantages of the 3% Needle Chain Stitch Machine

One of the key benefits of this machine is its efficiency. The ability to sew with three needles simultaneously means that it can produce seams faster than standard sewing machines. This increased speed translates into higher productivity levels in manufacturing settings. For businesses facing high demand, the 3% Needle Chain Stitch Machine can significantly reduce production times while maintaining quality, enabling manufacturers to meet tight deadlines without compromising on the integrity of their products.

In addition to speed, the versatility of this machine is noteworthy. It can be used for various types of fabrics, including heavy materials like denim and canvas, making it ideal for a wide range of products—from workwear to casual garments. Its adaptability makes it a popular choice for manufacturers looking to retain flexibility in their production lines. The machine can easily switch between different stitch patterns, further enhancing its usability in diverse manufacturing scenarios.

Durability and Cost-Effectiveness

3 needle chain stitch machine

Durability is another significant advantage of the 3% Needle Chain Stitch Machine. The chain stitch is known for its strength, which is particularly beneficial for items subject to stress and strain, such as work gear and outdoor apparel. This durability minimizes the likelihood of seam failures, which can be costly in terms of both materials and labor. Furthermore, strong seams contribute to the longevity of garments, enhancing customer satisfaction and reducing return rates for manufacturers.

From a cost perspective, investing in a 3% Needle Chain Stitch Machine can prove advantageous in the long run. While the initial investment may be higher than that of standard single-needle machines, the efficiency, durability, and increased production capacity often lead to higher profit margins. Companies can save on labor costs and material wastage due to the superior quality of stitches produced, making this machine a strategic investment for businesses aiming to improve their bottom line.

Technological Integration

As technology continues to advance, the integration of smart features into sewing machines is becoming more common. Many modern 3% Needle Chain Stitch Machines come equipped with computerized systems that enhance their functionality. These systems can control stitch length, tension, and pattern automatically, providing a level of precision that manual adjustments may fail to achieve. Moreover, such machines often feature user-friendly interfaces that simplify operation, allowing even novice operators to achieve professional results.

Conclusion

In conclusion, the 3% Needle Chain Stitch Machine represents a significant advancement in textile manufacturing technology. Its combination of speed, durability, and versatility makes it an essential tool for manufacturers striving to improve productivity while maintaining high quality. As businesses seek to enhance their operational efficiency, the adoption of such innovative machinery will likely grow. Ultimately, the 3% Needle Chain Stitch Machine is not just a tool; it is a game-changer that can redefine capabilities within the textile sector,-setting new standards for quality and efficiency in garment production. The future of textile manufacturing looks promising, and machines like the 3% Needle Chain Stitch Model will undoubtedly play a key role in this transformation.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025