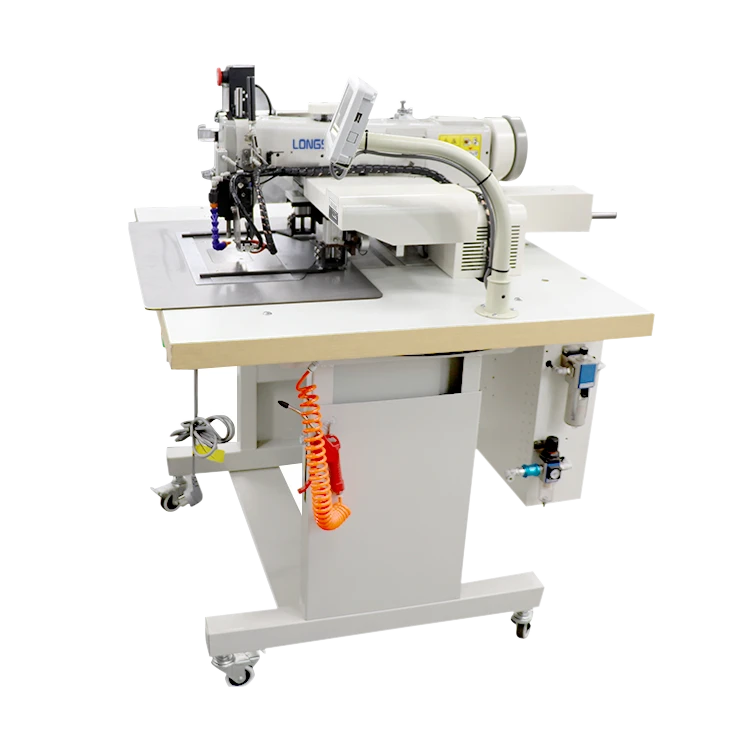

woven sack bag sewing machine

The Woven Sack Bag Sewing Machine A Vital Tool in Modern Manufacturing

In the rapidly evolving landscape of manufacturing, specialized machinery plays a crucial role in enhancing productivity and ensuring the quality of products. Among these essential machines, the woven sack bag sewing machine stands out due to its significant impact on the production of bags, particularly those used for agriculture, construction, and various industrial applications. This article explores the features, benefits, and applications of these machines in the modern manufacturing environment.

Woven sack bags, typically made from polypropylene or other synthetic materials, are designed to be durable and resistant to various environmental conditions. The sewing machine specifically tailored for these bags possesses unique characteristics that enable it to handle the thickness and strength of woven materials. Equipped with robust motors and specialized needles, the woven sack bag sewing machine ensures that the seams are strong and reliable, capable of withstanding heavy loads without breaking or tearing.

One of the most notable features of these machines is their versatility. Many models come equipped with multiple stitching options, allowing manufacturers to create different styles of sacks tailored to specific needs. Whether it's for storing grains, fertilizers, or construction materials, the ability to customize the stitch patterns ensures that the final product meets the required standards for durability and functionality.

woven sack bag sewing machine

The efficiency of woven sack bag sewing machines is another significant advantage. These machines can operate at high speeds, greatly increasing production rates compared to manual sewing methods. This efficiency is critical in industries where time is of the essence and where the demand for products is continually rising. By streamlining the bag-making process, manufacturers can meet tight deadlines while also reducing labor costs.

In addition to speed and versatility, modern machines come with advanced features such as computer numerical control (CNC) capabilities. This technology allows for precise control over the sewing process, ensuring uniformity across batches of products. Additionally, computerization can help in tracking production metrics, optimizing manufacturing processes, and reducing waste, which aligns with sustainable practices increasingly adopted by manufacturers.

The application of woven sack bags sewn by specialized machines extends beyond traditional uses. As industries evolve and new challenges emerge, these machines are being adapted for various applications, such as eco-friendly packaging solutions and innovative product designs. The growing emphasis on environmental sustainability has led to an increase in demand for reusable and recyclable woven bags, further highlighting the importance of cutting-edge machinery in addressing contemporary market trends.

In conclusion, the woven sack bag sewing machine is an indispensable asset in the manufacturing realm. Its ability to produce high-quality, durable, and versatile bags efficiently makes it a cornerstone of industries ranging from agriculture to construction. As technology continues to advance, these machines will no doubt evolve, further enhancing the capabilities and sustainability of woven bag production.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025