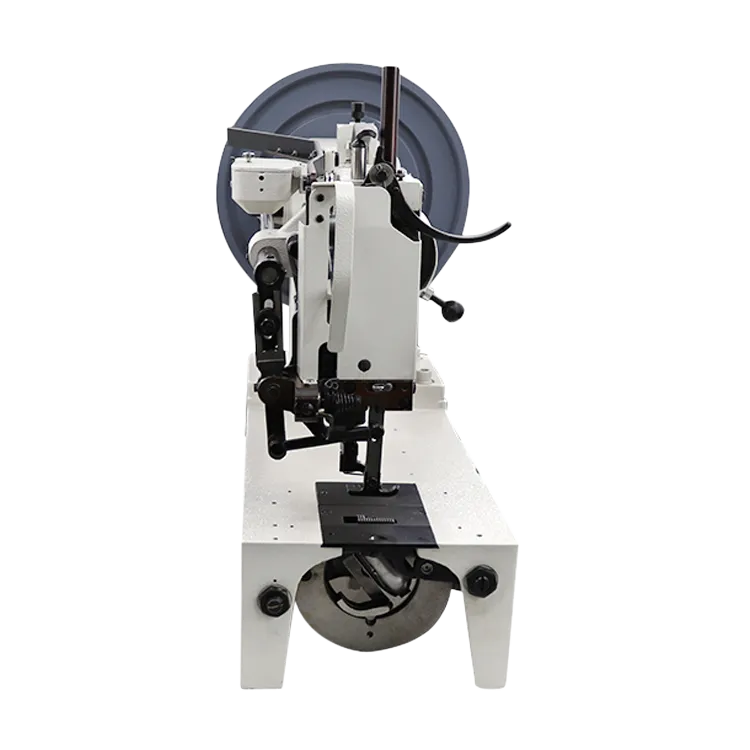

Upholstery Stitching Device for Precision Binding and Fabric Assembly Solutions

Understanding Upholstery Binding Machines A Comprehensive Overview

Upholstery binding machines play a critical role in the furniture and automotive industries, enabling manufacturers to create high-quality, durable, and aesthetically pleasing products. These specialized machines are designed to attach binding to various upholstery materials, ensuring edges are finished and protected while enhancing overall appearance. This article delves into the functions, types, benefits, and considerations surrounding upholstery binding machines.

Functions of Upholstery Binding Machines

At their core, upholstery binding machines serve the primary function of sewing materials together to create a finished edge. They are equipped to handle a variety of binding materials, including fabric, leather, and synthetic materials. The binding process not only secures the edges but also adds a decorative element to the upholstered item. Key functions include

1. Sewing The machine stitches the binding to the edges of the upholstery, creating a neat finish that withstands wear and tear. 2. Trimming Some machines are capable of trimming excess material while binding, ensuring a clean and professional look. 3. Applying Adhesives Certain models include adhesive application features that help secure the binding before stitching. 4. Customizable Settings Many upholstery binding machines allow users to adjust settings such as stitch length and tension, accommodating different materials and thicknesses.

Types of Upholstery Binding Machines

There are several types of upholstery binding machines available on the market, each tailored to specific needs

1. Walking Foot Sewing Machines These machines are popular in upholstery work due to their ability to feed multiple layers of thick materials evenly. They use a walking foot mechanism that moves the upper and lower materials together, minimizing slippage during the sewing process.

2. Binder Attachments for Sewing Machines For those who already own a sewing machine, there are binding attachments available that can be used to convert standard sewing machines into binding machines. These are typically more affordable and offer versatility for different projects.

3. Industrial Binding Machines Designed for high-volume production, these machines are robust and can handle larger projects efficiently. They often include features like automatic threading and faster sewing speeds, making them ideal for factories.

4. Portable Binding Machines These lightweight machines are suitable for on-site work or small-scale projects. They provide flexibility for upholstery professionals who need to work remotely or in varied environments.

Benefits of Using Upholstery Binding Machines

Utilizing upholstery binding machines offers numerous advantages

upholstery binding machine

- Cost Efficiency Automating the binding process reduces labor costs and time spent on finishing touches, leading to increased productivity.

- Quality Control These machines provide consistent quality, ensuring that every binding is uniform and meets exact specifications.

- Durability Properly bound edges increase the longevity of the upholstered items, making them more resistant to fraying and damage.

- Aesthetic Appeal Binding adds a professional touch to furniture and automotive interiors, contributing to the overall design and marketability of the product.

Considerations When Choosing an Upholstery Binding Machine

When selecting an upholstery binding machine, several factors should be considered

1. Material Compatibility Ensure that the machine can handle the materials you typically work with, whether they are lightweight fabrics or heavy-duty leather.

2. Production Volume Consider the scale of your operations. A high-volume production facility may require an industrial machine, while a small workshop might benefit from a portable option.

3. Budget Evaluate your budget constraints. While investing in a high-quality machine can be beneficial, there are also cost-effective options that perform well for smaller projects.

4. Ease of Use Look for machines that are user-friendly, with clear instructions and intuitive controls. This is especially important for those new to upholstery binding.

Conclusion

Upholstery binding machines are indispensable tools in the world of upholstery, facilitating the creation of high-quality finished products. By understanding the functions, types, benefits, and key considerations of these machines, professionals can make informed decisions that enhance their craft and drive business success. Whether for furniture, automotive, or custom projects, the right binding machine can make a significant difference in efficiency and quality.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025