Understanding the Functionality and Benefits of Compound Feed Sewing Machines for Various Applications

Understanding Compound Feed Sewing Machines

Compound feed sewing machines play a vital role in the textile industry, particularly in the manufacturing of garments and other fabric products. These machines are designed to handle various types of fabrics, including heavy, layered, and difficult-to-manipulate materials. This article explores what compound feed sewing machines are, their functionalities, advantages, and applications in the industry.

What is a Compound Feed Sewing Machine?

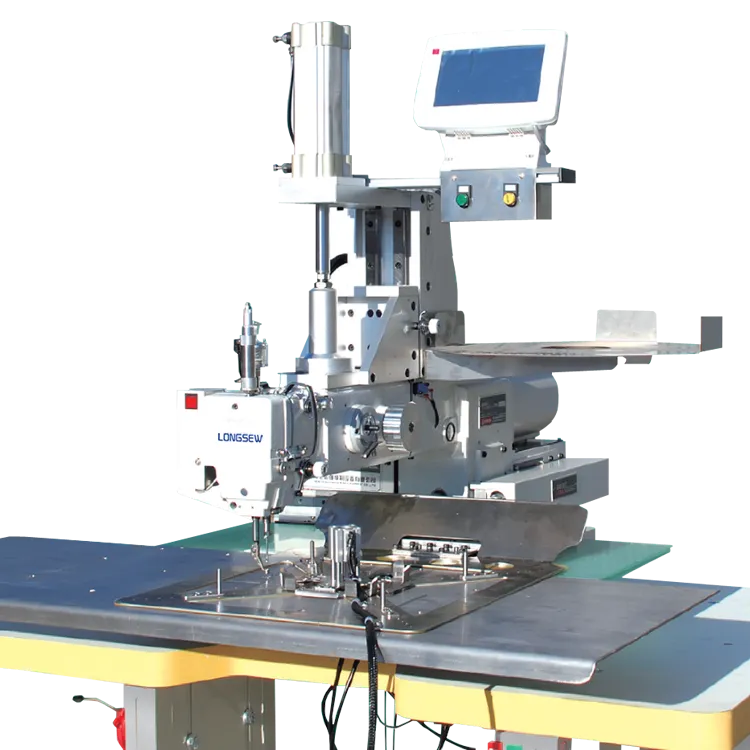

A compound feed sewing machine is a specialized sewing machine that utilizes a unique feeding mechanism to guide the fabric through the machine. Unlike standard sewing machines that only employ needle or walking foot feed, compound feed sewing machines utilize a combination of the needle feed, walking foot, and feed dogs. This combination allows for superior control over the fabric, enabling operators to sew straight seams and curves without puckering or distortion.

Key Features

1. Compound Feeding Mechanism The hallmark of compound feed machines is the coordinated movement of the needle, presser foot, and feed dogs. This compound action ensures that the upper and lower layers of fabric are fed simultaneously, which is essential when working with multiple layers or different fabric types.

2. Adjustable Presser Foot Many compound feed machines feature adjustable presser feet, allowing operators to customize the pressure applied to the fabric. This flexibility is important when working with delicate or stretchy fabrics, minimizing the risk of damage.

3. Versatile Stitching Options These machines can typically perform various stitches, including straight, zigzag, and decorative stitches. This versatility makes them suitable for numerous applications, from clothing production to industrial sewing tasks.

Advantages of Compound Feed Sewing Machines

The compound feed sewing machine offers several advantages over traditional sewing machines

- Improved Fabric Control One of the primary benefits is the machine's ability to control the movement of multiple fabric layers, reducing the chances of slipping or misalignment. This feature is particularly beneficial when sewing heavy textiles such as leather or denim.

what is compound feed sewing machine

- Enhanced Stitch Quality The synchronized feeding action ensures consistent stitch length and quality, resulting in a professional finish. This aspect is crucial in garment manufacturing, where stitch quality directly impacts the final product's appearance and durability.

- Reduced Puckering With its advanced feeding mechanism, a compound feed sewing machine minimizes the risk of puckering, which can occur with traditional sewing machines when working with challenging fabrics.

- Increased Productivity The efficiency of these machines allows operators to complete projects more quickly, optimizing workflow and increasing overall productivity in manufacturing environments.

Applications

Compound feed sewing machines are widely used across various sectors in the textile industry. Their ability to handle different fabric types makes them a popular choice for

- Garment Manufacturing They are frequently used to sew seams and hems in clothing production, especially for outerwear and heavy garments.

- Upholstery The machines are ideal for stitching upholstery fabrics in furniture manufacturing, ensuring durable and high-quality seams.

- Leather Goods Compound feed machines excel in working with leather, making them essential for the production of bags, belts, and other leather goods.

- Industrial Applications In industrial settings, these machines are utilized for sewing tarps, tents, and other heavy-duty items that require precise stitching.

Conclusion

In summary, compound feed sewing machines are indispensable tools in the textile industry, recognized for their advanced feeding mechanisms and versatility. They provide improved fabric control, stitch quality, and reduced puckering, making them ideal for a wide range of applications. As technology advances, these machines continue to evolve, further enhancing their capabilities and efficiency in modern sewing operations. Understanding and utilizing the benefits of compound feed sewing machines can significantly impact the quality and productivity of fabric-related manufacturing processes.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025