Top Sewing Machines for Crafting Perfect Shoes and Footwear Projects

The Evolution of Shoe Sewing Machines A Craftsmanship Revolution

Shoe-making is an age-old craft that has evolved significantly over the centuries. Behind every exquisite pair of shoes lies a vital tool the sewing machine. The invention and advancement of shoe sewing machines have propelled the craft into new heights of productivity and precision, transforming the shoe industry in ways that are still relevant today.

Historically, shoes were crafted by hand, which required immense skill and time. Artisans meticulously stitched together leather pieces, creating durable footwear that not only served its purpose but also reflected individual style. However, as demand for shoes grew, the limitations of manual labor became evident. Enter the shoe sewing machine.

The first shoe sewing machines emerged in the 19th century, revolutionizing shoe production. The introduction of these machines allowed for faster and more efficient stitching, enabling manufacturers to produce shoes in larger quantities. The early versions were rudimentary, designed primarily for straight stitching. However, they represented a significant leap forward for a craft that had remained largely unchanged for generations.

The Evolution of Shoe Sewing Machines A Craftsmanship Revolution

In the early 20th century, companies like Singer and Union Special began developing specialized machines for shoe manufacturing. These machines featured walking feet and presser feet that were tailored specifically for leather, allowing for precision that hand-sewing simply could not offer. Manufacturers could now produce shoes that were not only beautiful but also structurally sound and capable of withstanding daily wear.

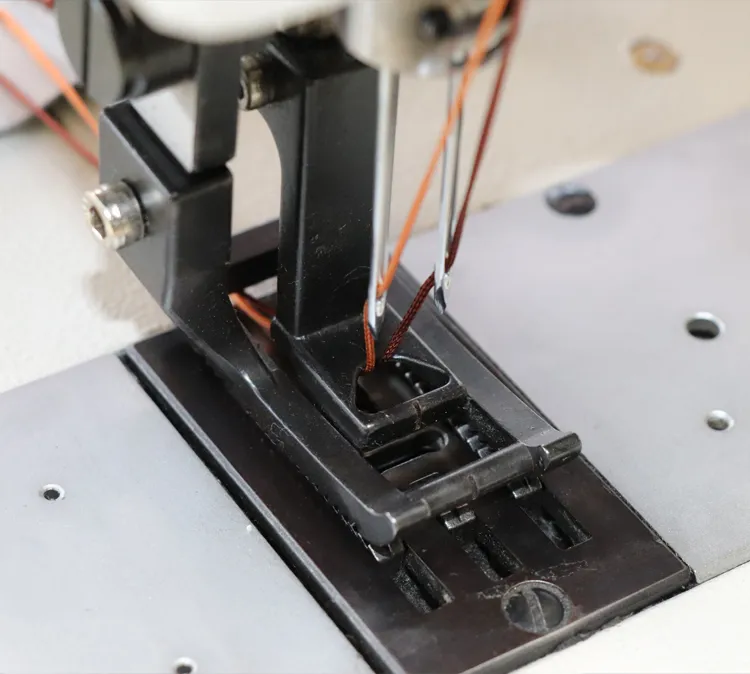

shoes sewing machine

Another innovative leap came with the introduction of computerized sewing machines in the late 20th century. These machines brought forth automation and programmability to shoe making, drastically improving efficiency and consistency. With the push of a button, machines could execute intricate patterns and stitches that would have required hours of skilled handwork. This opened the door for mass production without sacrificing quality, allowing brands to meet the growing consumer demand for affordable yet stylish footwear.

Moreover, the evolution of shoe sewing machines has had a profound impact on sustainability practices within the industry. As technology improved, so did the efficiency of the manufacturing process, reducing waste and energy consumption. Modern machines are increasingly designed with eco-friendly principles in mind, allowing manufacturers to produce environmentally-conscious footwear while maintaining high-quality standards.

Today, while many manufacturers rely on sophisticated machinery, the artistry of shoe-making remains. Skilled artisans often use sewing machines to create bespoke footwear, marrying traditional techniques with modern technology. This fusion showcases the versatility of shoe sewing machines and emphasizes that, even in an era dominated by automation, craftsmanship continues to thrive.

It is important to recognize that while technology has transformed the shoe sewing landscape, the importance of skilled labor remains paramount. The creative vision of designers combined with the efficiency of modern machines allows for a harmonious balance between innovation and tradition.

In conclusion, the shoe sewing machine has come a long way since its inception. From the early models that revolutionized manufacturing to today's advanced automated systems, these machines have transformed the footwear industry. As we look to the future, it is clear that shoe sewing machines will continue to play a crucial role in shaping the next generation of footwear, merging technology with artistry to create shoes that are both functional and fashionable.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025