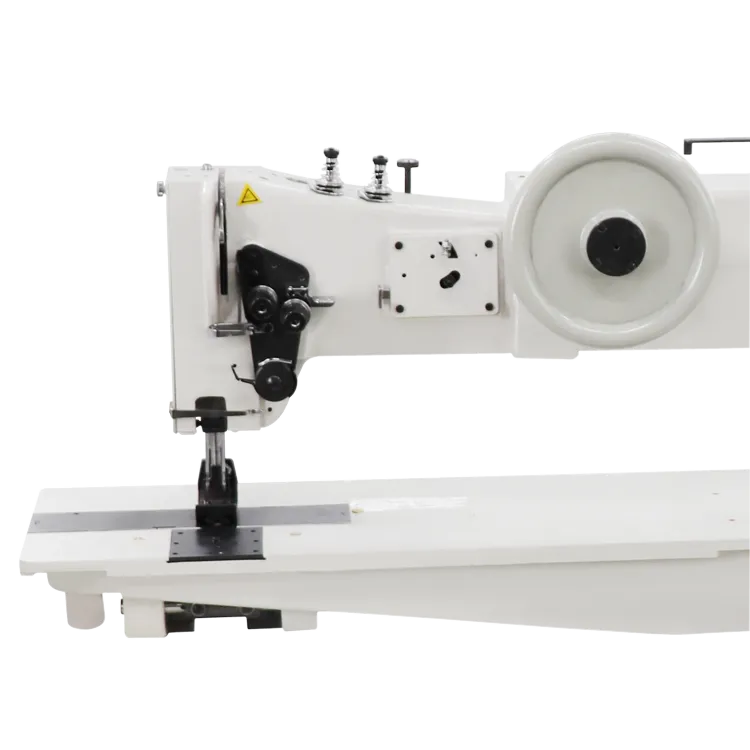

sewing machine used for leather

The Importance of Choosing the Right Sewing Machine for Leather Crafting

When it comes to leather crafting, selecting the right sewing machine is essential for achieving professional results. Leather is a unique material with its own set of challenges, making it crucial for artisans, hobbyists, and professionals alike to understand which sewing machines are best suited for this specialized task.

Firstly, it is important to recognize that leather is a heavy-duty fabric. Unlike cotton or polyester, leather is thicker, sturdier, and often more challenging to sew. This necessitates a sewing machine that is capable of handling not only the weight of the material but also the density and texture variations found in different types of leather. Therefore, a machine designed specifically for leather work or one with robust capabilities is crucial.

When searching for the ideal sewing machine for leather, there are several key features to consider

1. Stitching Power and Quality A sewing machine for leather should have a powerful motor that can sew through multiple layers of heavy fabric without skipping stitches or straining. Look for machines that can handle at least 12-14 ounces of leather and offer a variety of stitch types, including straight stitches and zigzag stitches. Walking foot machines are particularly effective, as they evenly feed the fabric under the needle while preventing slipping.

2. Heavy-Duty Needles Leather requires specialized needles, often referred to as leather or wedge needles, which have a sharp point designed to penetrate the tough fibers without causing tears. It is important to ensure that the sewing machine is compatible with these needles and that they are readily available.

sewing machine used for leather

3. Feed System A reliable feed system is crucial for sewing leather, as it allows the material to move smoothly through the machine. There are several types of feed systems, including drop feed and walking foot. A walking foot feed system is generally preferred for leather, as it works to grip the top layer of leather while the presser foot pushes the bottom layer, ensuring that both layers move evenly.

4. Adjustable Presser Foot Pressure Having the ability to adjust presser foot pressure can make a significant difference when sewing leather. Thicker materials require more pressure, while thinner materials require less. This feature allows for finer control, which can lead to better stitching quality and prevent damage to the leather.

5. Optional Walking Foot Attachment For those who may already own a sewing machine but want to dabble in leatherwork, an optional walking foot attachment can be a worthwhile investment. This attachment helps to grip and move layers of leather more effectively than standard presser feet, making it easier to achieve even stitching.

6. Space and Durability Larger projects or multiple bulky layers of leather often require ample space to maneuver the material effectively. Look for machines with a spacious throat area. Additionally, ensure that the machine is durable and constructed with a sturdy frame to handle the rigors of heavy-duty sewing.

Popular sewing machine brands that are frequently praised for their leather sewing capabilities include Sailrite, Brother, Juki, and Bernina. Each of these brands offers models specifically designed or equipped to handle leather, providing enthusiasts with choices suitable for various budgets and experience levels.

In conclusion, choosing the right sewing machine for leather is vital for achieving the desired results in any leather crafting project. By considering the specific features that cater to leather working, artisans can save time and effort while ensuring their creations are both beautiful and durable. Investing in a quality machine designed for leather will not only enhance the crafting experience but also produce professional-grade results that are sure to impress. Whether you are stitching simple wallets or complex leather bags, the right sewing machine will make all the difference.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025