Cylinder Bed Sewing Machines for Enhanced Versatility and Precision in Textile Projects

Understanding the Cylinder Bed Sewing Machine An Overview

In the realm of sewing and garment production, diverse types of sewing machines play integral roles in achieving specific outcomes. One type that holds particular significance in particular applications is the cylinder bed sewing machine. This specialized machine is designed to tackle sewing challenges that flatbed machines may struggle with, offering unique capabilities that can significantly enhance productivity and quality in sewing operations.

Design and Features

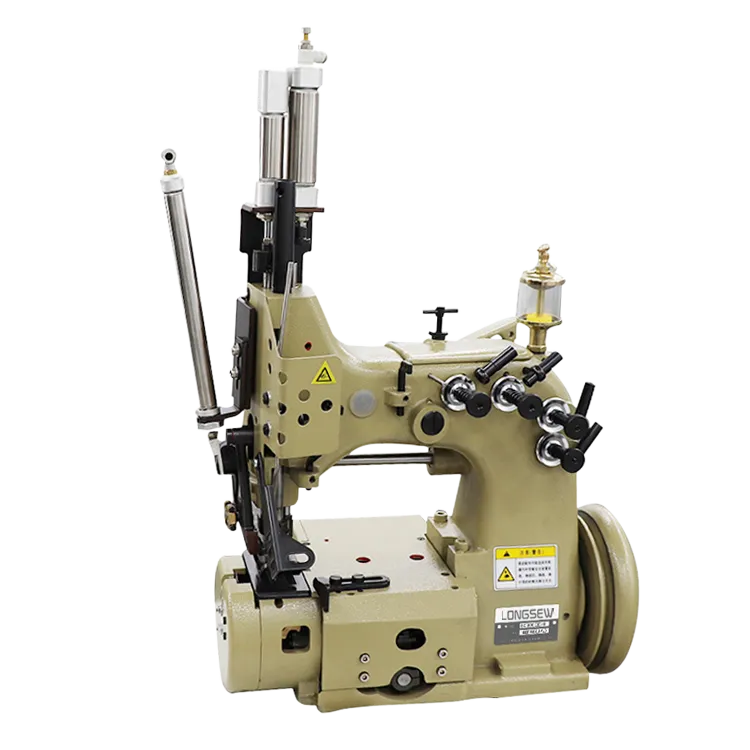

The hallmark feature of a cylinder bed sewing machine is its cylindrical arm. Unlike traditional flatbed sewing machines, which have a flat surface, the cylinder bed design employs a rounded bed that facilitates the sewing of tubular fabrics and difficult-to-reach areas. This design is especially advantageous when working with items such as sleeves, cuffs, and other curved or tubular sections of fabric that are common in garment production.

The cylinder bed machine typically features a smaller needle plate, which allows for greater maneuverability and precision when sewing. This is particularly beneficial when working on delicate tasks that require intricate stitching or when sewing in areas where space is constrained. Additionally, many cylinder bed sewing machines come equipped with specialized attachments and tools that enhance their functionality, making them versatile options for various sewing applications.

Benefits in Garment Production

One of the key advantages of using a cylinder bed sewing machine is its ability to sew with greater efficiency in specific scenarios. For garment manufacturers, this translates to faster production times and higher throughput, particularly when dealing with complex patterns or designs that necessitate sewing in tight spaces. The rounded bed allows for the fabric to be easily maneuvered around the arm of the machine, minimizing fabric distortion and ensuring greater consistency in stitching quality.

sewing machine cylinder bed

Furthermore, cylinder bed machines are also advantageous for sewing thicker materials. The design of the machine accommodates heavier fabrics that may be cumbersome or challenging to handle on a flatbed machine. This characteristic makes cylinder bed machines a preferred choice for sewing items such as bags, soft furnishings, and other specialty textile goods.

Use in Specialized Industries

In addition to garment production, cylinder bed sewing machines are widely utilized in several specialized industries. For instance, in the leatherworking sector, where precision and finesse are crucial, the cylinder bed design allows for seamless stitching on leather products such as jackets, handbags, and shoes. The machine's ability to navigate around contours and curves makes it indispensable for artisans and manufacturers in this trade.

Similarly, the automobile industry also leverages the capabilities of cylinder bed sewing machines for upholstery work. They are employed to create vehicle interiors, including seat covers and other fabric components, where intricate sewing is required. The efficiency and quality offered by these machines have made them a standard tool in automotive upholstery workshops around the globe.

Conclusion

In conclusion, the cylinder bed sewing machine is a vital piece of equipment in the sewing industry, offering functionality that caters to specialized sewing needs. Its unique design enhances the ability to work with tubular fabrics, providing manufacturers with the efficiency and precision necessary for high-quality outputs. Whether in garment production, leatherworking, or automotive upholstery, the cylinder bed sewing machine continues to be a trusted and essential tool. As technology advances, these machines are likely to evolve further, integrating new features that enhance their capability and ease of use, ensuring they remain relevant in a fast-paced industry. For those engaged in sewing, understanding the advantages and specific uses of the cylinder bed sewing machine can lead to smarter decisions in selecting equipment that meets their production requirements.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025