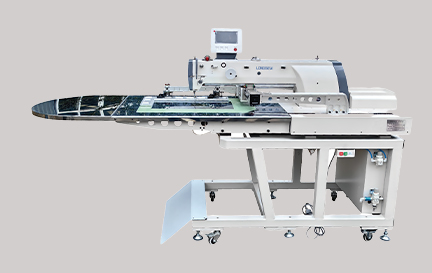

Enhanced Safety Rope Stitching Machine for Reliable Performance and Durability

The Importance of Safety Rope Sewing Machines in Modern Manufacturing

In today's fast-paced manufacturing environment, the need for safety, precision, and efficiency has never been greater. One critical piece of equipment that plays a pivotal role in producing high-quality safety ropes is the safety rope sewing machine. These specialized machines are designed not just for speed, but also for the exceptional quality and strength that safety ropes require in various applications, such as climbing, rescue operations, and industrial safety.

Understanding Safety Ropes

Safety ropes are essential components used in various activities where fall protection or securing objects is vital. These ropes are typically made from sturdy materials such as nylon, polyester, or polypropylene, which offer excellent tensile strength, resistance to abrasion, and durability. Given the high stakes involved in activities such as rock climbing, construction, or rescue operations, the quality of safety ropes cannot be compromised. This is where the importance of sewing machines specifically designed for safety ropes comes into play.

The Role of Safety Rope Sewing Machines

Safety rope sewing machines are engineered to handle the unique demands of sewing thick, robust materials. Unlike standard sewing machines, these machines incorporate features that ensure strong, secure stitching capable of withstanding heavy loads and significant stress. Some of the key features that distinguish safety rope sewing machines include

1. Heavy-Duty Construction These machines are built to endure the rigors of sewing tough materials, featuring robust frames and powerful motors that can handle multiple layers of heavy-duty fabric.

2. Specialized Needles and Threads Safety rope sewing machines utilize specialized needles and threads that can penetrate thick materials without breaking or causing damage. The threads are often designed to provide additional strength and resistance to wear and tear.

3. Advanced Stitching Techniques Many of these machines offer various stitching options, such as zigzag or triple stitch patterns, which enhance the overall durability and load-bearing capacity of the sewn rope. This is crucial for ensuring the integrity of safety equipment.

safety rope sewing machine

5. Quality Control Features To maintain high safety standards, many machines are equipped with sensors and quality control features that detect defects in stitching, preventing subpar products from reaching the market.

Applications of Safety Rope Sewing Machines

The applications for safety rope sewing machines are vast and varied. Industries such as construction, outdoor sports, maritime, and rescue services all rely heavily on these devices to produce safety equipment. For instance

- Climbing and Mountaineering Safety ropes used in climbing need to be reliable and secure, with seams that can withstand the dynamic forces exerted during falls. - Industrial Safety In industries where workers are exposed to heights or hazardous conditions, safety ropes are essential for fall protection systems. The integrity of these ropes is paramount, as they are often the last line of defense against serious injuries.

- Rescue Operations Firefighters and rescue organizations depend on strong, reliable ropes during emergency operations. Each seam must be meticulously crafted to ensure the life-saving ropes perform effectively under extreme conditions.

The Future of Safety Rope Sewing Machines

As technology advances, so too does the manufacturing process for safety ropes. The integration of automation and smart technology into sewing machines is becoming more common. Features such as programmable stitching patterns and real-time monitoring of stitch quality are setting new standards in the industry. Additionally, with the growing emphasis on sustainability, manufacturers are exploring eco-friendly materials and processes, creating a demand for machines that can accommodate these innovations.

Conclusion

Safety rope sewing machines are indispensable in the manufacturing of high-quality safety ropes. Their ability to deliver strong, reliable, and precise stitching ensures that ropes meet stringent safety standards required in various industries. As the demand for safety gear continues to rise globally, investing in advanced sewing technology will be key for manufacturers looking to enhance their production capabilities and uphold the highest safety standards. By prioritizing quality in the manufacturing process, industries can ensure that their workers and clients remain safe, secure, and confident in the equipment they use.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025