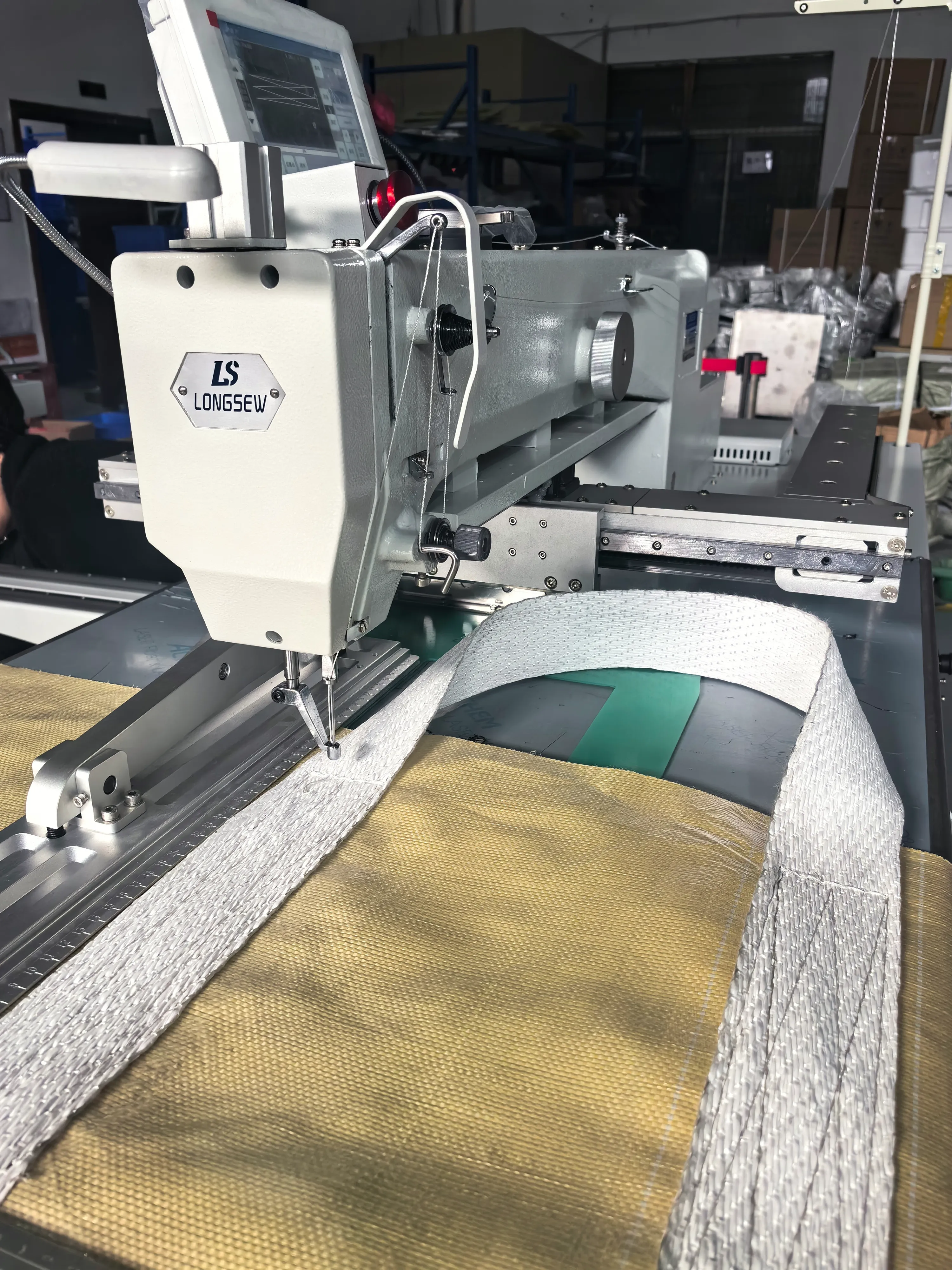

Hand Stitching Machine for PP Bags with Precise Control and Durable Performance

The Innovative PP Bag Hand Stitching Machine

In the world of packaging and manufacturing, the importance of durable and reliable bags cannot be overstated. Polypropylene (PP) bags have become increasingly popular due to their strength, durability, and eco-friendliness. As the demand for these bags rises, so does the need for efficient production methods. One such innovation in the realm of PP bag manufacturing is the PP bag hand stitching machine, a tool that enhances productivity while ensuring high-quality stitching.

Understanding PP Bags

Polypropylene bags are made from a thermoplastic polymer, commonly used for a variety of applications ranging from food packaging to agricultural products. Their lightweight nature, coupled with resistance to moisture and chemicals, makes them an ideal choice for both industrial and consumer goods. The demand for sustainable packaging solutions has further propelled the use of PP bags, as they can be recycled and reused, contributing to a more environmentally friendly approach.

The Role of Hand Stitching

While modern machinery has revolutionized the manufacturing process, there remains a niche for hand-stitched products, particularly in markets where quality and attention to detail are paramount. Hand stitching offers a level of craftsmanship that automatic machines may not always achieve. However, this does not mean that productivity should be compromised. This is where the PP bag hand stitching machine comes into play.

Features of the PP Bag Hand Stitching Machine

The PP bag hand stitching machine is designed to combine the precision of machine stitching with the artistry of handwork. Here are some of its key features

1. Manual Operation with Automation Support While the machine requires an operator to guide it, many models incorporate automated elements that streamline the stitching process, ensuring consistent quality across batches.

2. Adjustable Stitch Length Operators can customize the stitch length according to specific requirements, allowing for versatility in different bag styles and sizes.

pp bag hand stitching machine

4. Durability Constructed from high-quality materials, these machines are designed to withstand the rigors of daily use, ensuring longevity and reliability.

5. Easy Maintenance Regular maintenance protocols are simple, allowing operators to keep the machine in top condition without constant professional intervention.

Benefits of Using a PP Bag Hand Stitching Machine

1. Increased Productivity By combining the speed of machine operation with the quality of hand stitching, manufacturers can significantly increase their output without sacrificing quality.

2. Skill Development The use of these machines provides an opportunity for workers to develop their stitching skills, fostering an environment of craftsmanship and expertise.

3. Cost-Effective Producing high-quality PP bags through hand stitching can be more cost-effective than relying solely on full automation, especially for smaller batches.

4. Flexibility Manufacturers can quickly adapt to changing market demands, producing customized bags as needed without long reconfiguration times.

5. Reducing Waste Precision stitching minimizes material waste, making the production process more sustainable and environmentally friendly.

Conclusion

The PP bag hand stitching machine represents a significant advancement in the evolution of bag manufacturing. By marrying traditional handcraft techniques with modern technology, this innovation not only enhances productivity and efficiency but also elevates the quality of the final product. As industries continue to seek more sustainable and efficient manufacturing solutions, the PP bag hand stitching machine stands out as a viable answer to meet these demands. Its ability to combine quality with productivity ensures that it will play a crucial role in the future of polypropylene bag production, making it an invaluable asset for manufacturers worldwide.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025