High-Quality PP Woven Sack Bag Sewing Machine - Efficient & Durable Solutions

The Essential Role of PP Woven Sack Bag Sewing Machines in Modern Packaging

In today’s fast-paced manufacturing landscape, packaging plays a crucial role in ensuring product safety, convenience, and branding. Among the various packaging materials available, polypropylene (PP) woven sacks have gained immense popularity due to their durability, lightweight nature, and cost-effectiveness. To efficiently produce these sacks, the role of PP woven sack bag sewing machines cannot be overstated.

PP woven sacks are used extensively in industries such as agriculture, food, chemicals, and construction to package grains, fertilizers, and various other bulk products. The benefits of using PP woven bags are many; they are resistant to moisture, can be produced in various sizes and strengths, and are also recyclable, making them an environmentally friendly option. However, the manufacturing of these bags requires precise and efficient sewing processes, which is where specialized sewing machines come into play.

The Essential Role of PP Woven Sack Bag Sewing Machines in Modern Packaging

One of the significant advantages of using a dedicated sewing machine for PP woven sacks is the increase in production efficiency. These machines can operate at high speeds, allowing manufacturers to produce large quantities of bags in a relatively short period. This efficiency not only meets the growing demand for woven sacks in various industries but also helps reduce labor costs and time, ultimately enhancing overall productivity.

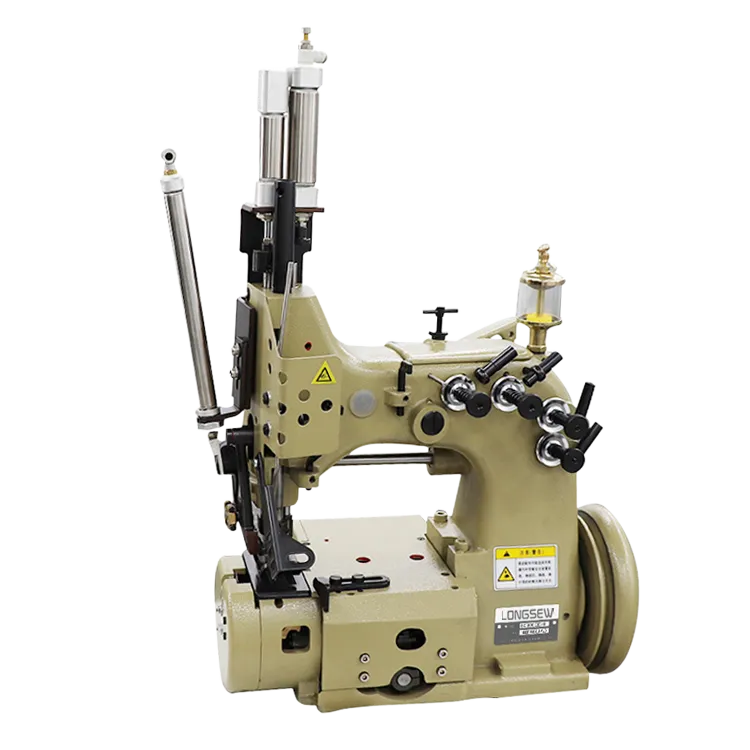

pp woven sack bag sewing machine

Moreover, the quality of the seams produced by these machines is of utmost importance. The strength and durability of a sewn seam determine the performance of the sack in real-world applications. A poorly sewn bag can lead to product spillage, waste, and customer dissatisfaction. PP woven sack bag sewing machines are designed to create strong, reliable seams that maintain the integrity of the bags during transportation and storage.

In addition to their efficiency and stitching quality, modern PP woven bag sewing machines come with advanced technological features. Many machines are now equipped with computer controls that allow for precise adjustments, monitoring production metrics, and even integrating with other manufacturing systems. This technological advancement contributes to the overall automation of the production process, further enhancing productivity and reducing human error.

As environmental concerns continue to grow, manufacturers are also focusing on producing more sustainable packaging solutions. The recyclability of PP woven sacks is a critical factor, and thus sewing machines that reduce waste during the production process are increasingly in demand. Sustainable practices in the sewing process not only contribute to a greener footprint but also appeal to environmentally conscious consumers.

In conclusion, PP woven sack bag sewing machines play an indispensable role in modern packaging operations. Their specialized design, efficiency, and ability to create high-quality seams ensure that manufacturers can meet the demands of various industries while maintaining product integrity and sustainability. As the packaging industry evolves, investing in advanced sewing technology will remain crucial for businesses aiming to stay competitive in the market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025