Innovative Machine for Crafting Long Arm and High Arm Sails Efficiently

Understanding Long Arm and High Arm Sail Making Machines

Sail-making has long been an essential part of maritime activities, enabling the design and production of sails for various types of vessels. As the demands of the sailing industry continue to evolve, the technologies and equipment used in sail production have also advanced significantly. One such innovation is the long arm and high arm sail-making machine, which plays a crucial role in enhancing efficiency and precision in sail manufacturing.

The Basics of Sail Making

Sails are the primary source of propulsion for sailing vessels, utilizing wind power to provide movement. The process of sail-making involves cutting, stitching, and finishing fabric materials, typically made from durable and weather-resistant materials like Dacron or laminate. Traditionally, this work was done by hand, requiring significant labor and skill. However, advancements in technology have led to the introduction of specialized machines that streamline this process.

Features of Long Arm and High Arm Sail Making Machines

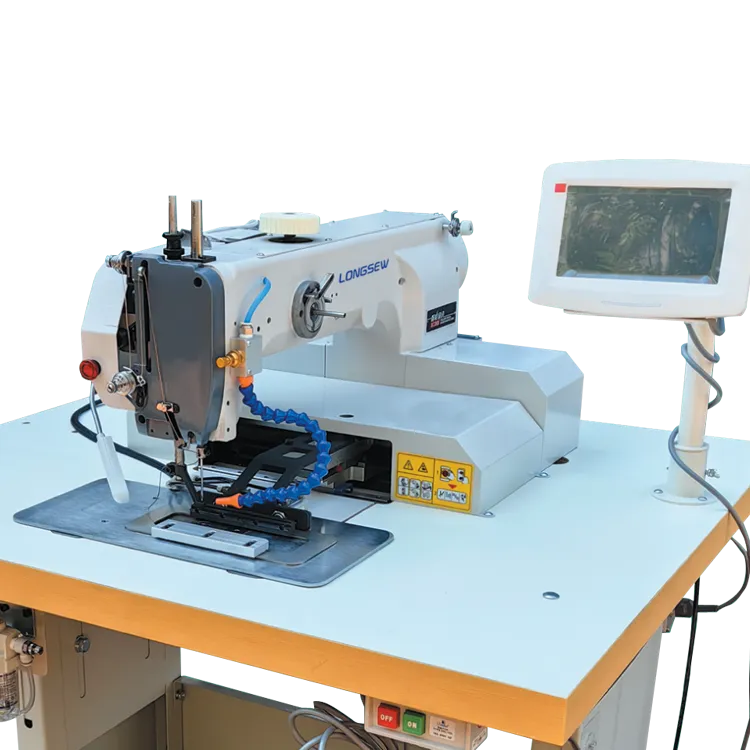

Long arm and high arm sail-making machines are specifically designed to accommodate the unique shapes and sizes of sails. The long arm feature allows for extended reach, providing the ability to handle larger sail fabrics without the constraints of a standard sewing machine. This is particularly beneficial when working with expansive materials, as it minimizes the need to reposition the fabric, saving both time and effort.

On the other hand, the high arm feature elevates the arm of the sewing machine, allowing for greater clearance when working on bulkier sail components. This is especially useful for tasks that involve stitching multiple layers of fabric together or adding reinforcements at critical stress points in the sail. The combination of these two features enables manufacturers to produce high-quality sails with better structural integrity and longevity.

long arm & high arm sail making machine

Benefits of Using Long Arm and High Arm Machines

1. Increased Efficiency The design of these machines significantly reduces the time spent on sewing operations. Manufacturers can produce sails faster, meeting market demands without compromising quality.

2. Precision and Quality With advanced stitching capabilities, these machines ensure accurate and uniform stitches. This precision contributes to a stronger and more reliable sail, essential for safety and performance on the water.

3. Versatility Long arm and high arm machines can handle various sail types, whether for recreational vessels, racing yachts, or commercial shipping. Their adaptability makes them valuable in diverse sail-making environments.

4. Reduced Labor Costs By automating many of the sewing processes, businesses can reduce the number of skilled labor hours required for sail production, leading to lower operational costs.

Conclusion

The integration of long arm and high arm sail-making machines into the manufacturing process represents a significant advancement in the maritime industry. These machines not only enhance productivity but also ensure the durability and performance of sails that are critical for safe and efficient sailing. As the sailing industry continues to innovate, the technology behind sail-making machines will undoubtedly play a pivotal role in shaping the future of how sails are designed and produced. Investing in such equipment enables manufacturers to keep up with industry trends, push boundaries in sail design, and ultimately contribute to the evolving art of sailing. The long arm and high arm sail-making machines are thus a testament to the fusion of tradition and modern technology in the pursuit of excellence on the seas.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025