leather machinery

The Evolution and Significance of Leather Machinery

The leather industry has undergone significant transformations over the centuries, evolving from rudimentary techniques to highly sophisticated machinery that enhances production efficiency and product quality. Leather machinery plays a crucial role in this industry, influencing everything from tanning processes to the finishing touches on high-quality leather goods.

Historically, leather production involved manual labor and basic tools. Craftsmen relied on their skills to process animal hides, a method that, while effective, limited scalability and consistency. However, as demand for leather products surged in the 19th century, particularly with the rise of industrialization, there was a pressing need for more efficient manufacturing methods. This led to the development of specialized machinery designed to automate and streamline various stages of leather processing.

One of the most significant advancements in leather machinery was the introduction of automated tanning systems. Traditional tanning methods were labor-intensive and time-consuming, requiring extensive manual handling. Modern tannery machines, such as drum tumblers and vacuum dryers, have revolutionized this process. They improve not only the speed of tanning but also the quality and uniformity of the leather produced. By automating these processes, manufacturers can achieve consistency in their products while reducing waste and labor costs.

leather machinery

Additionally, cutting and shaping machines have transformed the way leather is prepared for crafting. Laser cutting technology allows for intricate designs to be created with precision, enabling manufacturers to reduce material waste and lower production times. These advancements provide artisans and designers with greater creative freedom, allowing them to bring more innovative products to market.

Finishing machinery, including coating and embossing machines, has also seen remarkable improvements. These machines are essential for adding protective layers, colors, and textures to leather, ensuring durability while enhancing aesthetics. The ability to produce leather with various finishes not only meets the diverse preferences of consumers but also opens up new markets for leather products.

Furthermore, the rise of sustainable practices in the leather industry has prompted the development of eco-friendly machinery. Technologies that minimize harmful emissions and use organic tanning agents are becoming increasingly common, reflecting a growing awareness of environmental issues among manufacturers. This shift not only addresses consumer demand for responsibly sourced products but also contributes to the long-term viability of the leather industry.

In conclusion, leather machinery plays a vital role in the evolution of the leather industry. From improving efficiency and quality to embracing sustainability, these machines have transformed how leather is produced. As technology continues to advance, the future of leather machinery looks promising, paving the way for innovative products that honor traditional craftsmanship while meeting modern demands.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

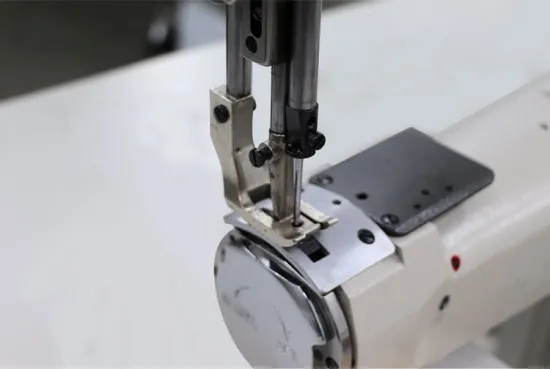

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025