ม.ค. . 09, 2025 10:44

Back to list

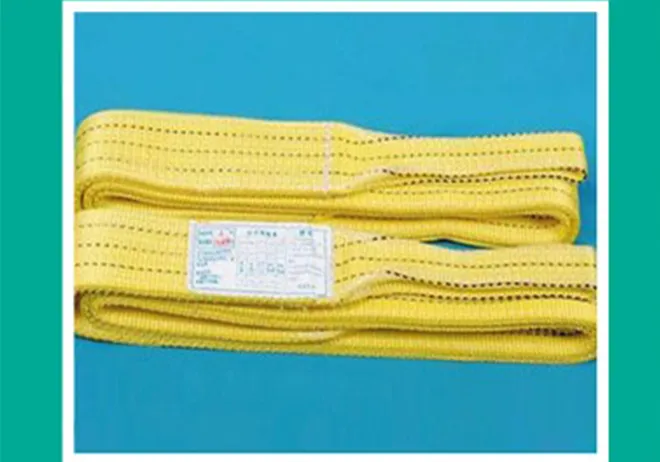

FIBC Bag / Jumbo Bag / Big Bag Automatic Computerized Pattern Sewing Machine For Bulk Bag Loop Ring or Lifting Belt LS200-5020

In the ever-evolving world of industrial manufacturing, efficiency, durability, and innovation stand at the forefront of operations. The jumbo bag stitching machine is a pivotal player in this domain, crafted to redefine expectations in bulk packaging. As a flagship in automated textile machinery, these machines offer unparalleled performance in the production of flexible intermediate bulk containers (FIBCs), commonly known as jumbo bags.

From an authoritative standpoint, jumbo bag stitching machines are engineered with cutting-edge technology and comply with international quality standards such as ISO 9001 and CE certifications. Their design takes into account the rigorous demands of bulk packaging, including load capacity, fabric thickness, and tensile strength. This ensures that each stitched jumbo bag can withstand the mechanical stresses it may face during transportation and storage. Industry specialists frequently recommend these machines due to their proven reliability and robust construction. Trustworthiness is further augmented by the meticulous attention to detail in the design and manufacturing of jumbo bag stitching machines. Top-tier brands offer extended warranties and after-sales service agreements, cementing their commitment to customer satisfaction. Moreover, the integration of modern technologies like IoT and AI in some models facilitates real-time monitoring and diagnostic capabilities. This enables predictive maintenance and swift response to potential issues, thereby extending the machine's lifespan and maintaining high performance levels. In summary, the jumbo bag stitching machine is an indispensable asset for manufacturers aiming to enhance efficiency and product quality in bulk packaging. Its advantages derived from increased productivity, comprehensive training, adherence to international standards, and advanced technological features create a compelling case for its adoption. As the landscape of industrial manufacturing continues to advance, the jumbo bag stitching machine remains a beacon of innovation and reliability, steering businesses towards a future of seamless operational excellence.

From an authoritative standpoint, jumbo bag stitching machines are engineered with cutting-edge technology and comply with international quality standards such as ISO 9001 and CE certifications. Their design takes into account the rigorous demands of bulk packaging, including load capacity, fabric thickness, and tensile strength. This ensures that each stitched jumbo bag can withstand the mechanical stresses it may face during transportation and storage. Industry specialists frequently recommend these machines due to their proven reliability and robust construction. Trustworthiness is further augmented by the meticulous attention to detail in the design and manufacturing of jumbo bag stitching machines. Top-tier brands offer extended warranties and after-sales service agreements, cementing their commitment to customer satisfaction. Moreover, the integration of modern technologies like IoT and AI in some models facilitates real-time monitoring and diagnostic capabilities. This enables predictive maintenance and swift response to potential issues, thereby extending the machine's lifespan and maintaining high performance levels. In summary, the jumbo bag stitching machine is an indispensable asset for manufacturers aiming to enhance efficiency and product quality in bulk packaging. Its advantages derived from increased productivity, comprehensive training, adherence to international standards, and advanced technological features create a compelling case for its adoption. As the landscape of industrial manufacturing continues to advance, the jumbo bag stitching machine remains a beacon of innovation and reliability, steering businesses towards a future of seamless operational excellence.

Previous:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025