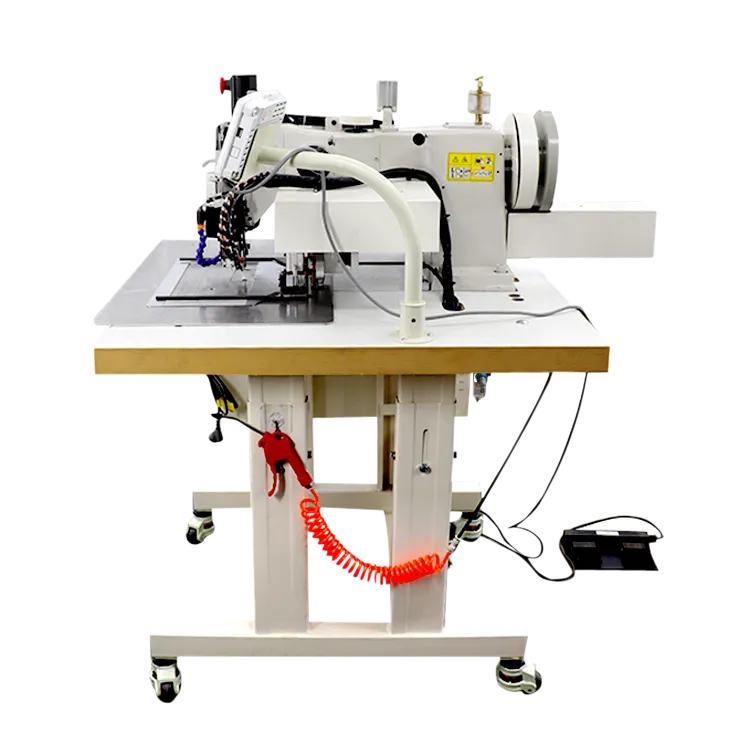

FIBC Bag / Jumbo Bag / Big Bag Automatic Computerized Pattern Sewing Machine For Bulk Bag Loop Ring or Lifting Belt LS200-5020

In the world of industrial packaging, efficiency and durability are paramount. Enter the jumbo bag stitching machine—a revolutionary tool designed to meet the growing demands of heavy-duty packaging solutions across various industries. This piece of advanced machinery is instrumental in producing FIBC (Flexible Intermediate Bulk Containers), commonly known as jumbo bags. These bags are cornerstone solutions for industries requiring bulk transportation, from agriculture to construction.

A jumbo bag stitching machine stands out due to its sophisticated engineering, which ensures consistent, high-quality seams that are integral for maintaining the structural integrity of jumbo bags. Unlike traditional sewing machines, these machines are designed to handle thick, heavyweight fabrics such as woven polypropylene, commonly used in jumbo bag manufacturing. This ensures that the bags can support the substantial weights they are intended to carry, sometimes ranging between 500 kg to 2000 kg.

One key feature that elevates the functionality of a jumbo bag stitching machine is its advanced automation capabilities. This automation not only speeds up the production process but significantly reduces human error, ensuring each stitch is precise and uniform. Cutting-edge models offer programmable settings, which allow operators to adjust stitch patterns and tensions tailored to specific bag designs. The result is a seamless product that's both reliable and trusted by industries globally.

The machine’s robust construction is crafted from high-quality materials, ensuring its longevity and resistance to wear and tear, providing an exceptional return on investment for manufacturers. With easy-to-use controls and minimal maintenance requirements, operators can swiftly adapt to any changes in production demands. Regular updates and digital interfaces also provide real-time monitoring, further enhancing manufacturing efficiency.

jumbo bag stitching machine

When discussing expertise in the manufacturing of jumbo bags, it’s crucial to understand the significance of the double and triple-needle stitching techniques provided by these machines. These techniques are crucial in preventing seam slippage when the bag is filled to capacity, a problem often encountered with lower-quality stitching equipment. Furthermore, some models incorporate ultrasonic welding functions, an innovative technique that bonds fibers without the need for thread, enhancing both durability and leak resistance.

Authorities in industrial packaging endorse the use of jumbo bag stitching machines for their unrivaled performance and reliability. They are a testament to the advancements in industrial automation and are trusted by professionals worldwide. They deliver superior quality products that meet strict international standards for safety and functionality.

For businesses keen on integrating trustworthy solutions into their production lines, investing in a jumbo bag stitching machine represents a commitment to quality and efficiency. As industries continue to evolve, the need for reliable, scalable, and efficient solutions will ensure that these machines remain an invaluable asset to manufacturers around the globe. By investing in such technology, industries solidify their market presence and build brand trust, ultimately leading to enhanced customer satisfaction and long-term business success.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025