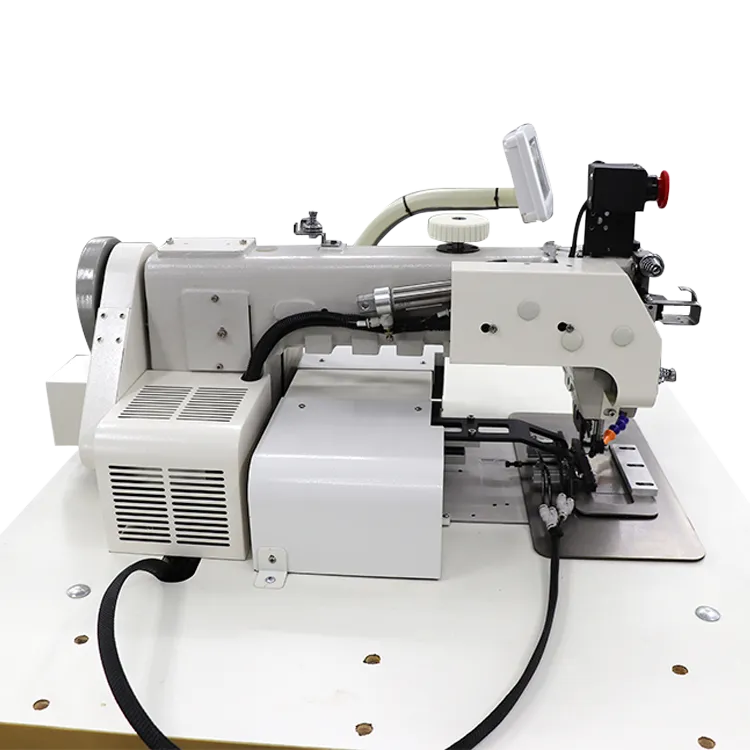

industrial sewing machine straight stitch and zig zag

The Versatile World of Industrial Sewing Machines Straight Stitch and Zigzag

In the dynamic realm of textile production, industrial sewing machines serve as indispensable workhorses, driving efficiency and precision in garment manufacturing. Among the myriad functions these machines perform, the straight stitch and zigzag stitch are two fundamental techniques that cater to a wide array of sewing needs. Understanding their distinct purposes, applications, and benefits can enhance the efficiency of any sewing operation, from small-scale workshops to large-scale factories.

Straight Stitch The Foundation of Sewing

The straight stitch is arguably the most basic and widely used stitch in sewing. It is characterized by a simple, straight line of stitches that create a robust seam, making it the foundation for almost every sewing project. Industrial sewing machines equipped for straight stitching are designed for durability and speed, capable of handling multiple layers of fabric and various materials, from lightweight fabrics to heavy denim.

One of the primary advantages of straight stitching is its strength and reliability. When two pieces of fabric are sewn together with a straight stitch, the seam is often stronger and less likely to unravel compared to other stitch types. This strength is crucial for assembling garments that undergo regular stress and strain, such as jeans or workwear.

Moreover, straight stitches are highly versatile. They can be used for a variety of applications, including

1. Construction Seams The primary seams used to assemble garments. 2. Topstitching Adding decorative stitches on the exterior of a garment for style or reinforcement. 3. Hemming Finishing the edges of fabric to prevent fraying.

However, while the straight stitch is essential, it does have limitations. It typically lacks flexibility, which becomes apparent when sewing fabrics that require stretch, such as knits or spandex. This is where the zigzag stitch comes into play.

industrial sewing machine straight stitch and zig zag

Zigzag Stitch Embracing Flexibility

The zigzag stitch, in contrast to the straight stitch, offers a more flexible and forgiving approach to sewing. This stitch creates a series of “zigs” and “zags” that allow the fabric to stretch, making it ideal for working with elastic materials. Industrial sewing machines that include zigzag functions are often versatile and can easily transition from one stitch type to another, catering to the evolving demands of different projects.

The primary benefits of the zigzag stitch include

1. Stretch and Recovery The zigzag stitch’s design allows it to expand and contract along with stretchy fabrics, making it perfect for items like activewear, swimsuits, and fitted garments. 2. Preventing Fraying The zigzag stitch can be used along raw edges to help prevent fraying, extending the lifespan of the garment. 3. Decorative Applications The zigzag stitch can also be employed for decorative purposes, adding visual interest to hems and seams.

The versatility of the zigzag stitch allows it to play a crucial role in modern fashion, where elasticity and fit are paramount. As trends evolve and consumer preferences shift towards comfort and functionality, the importance of zigzag stitching in industrial settings continues to grow.

Choosing the Right Machine

When selecting an industrial sewing machine, it is essential to consider the types of stitches needed for your production line. Machines that offer both straight and zigzag stitching capabilities provide the flexibility to handle a wide range of sewing tasks. Moreover, features like adjustable stitch length and width, speed settings, and specialized feet can enhance the functionality and precision of sewing operations.

In summary, both straight and zigzag stitches play vital roles in the textile industry. Their unique characteristics cater to different fabric types and sewing applications, making them essential tools for any industrial sewing operation. By understanding the strengths and applications of these stitches, manufacturers can optimize their production processes, ensuring high-quality outcomes that meet the demands of today’s market. As the fashion landscape continues to evolve, the mastery of these fundamental techniques will remain crucial for success in garment manufacturing.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025