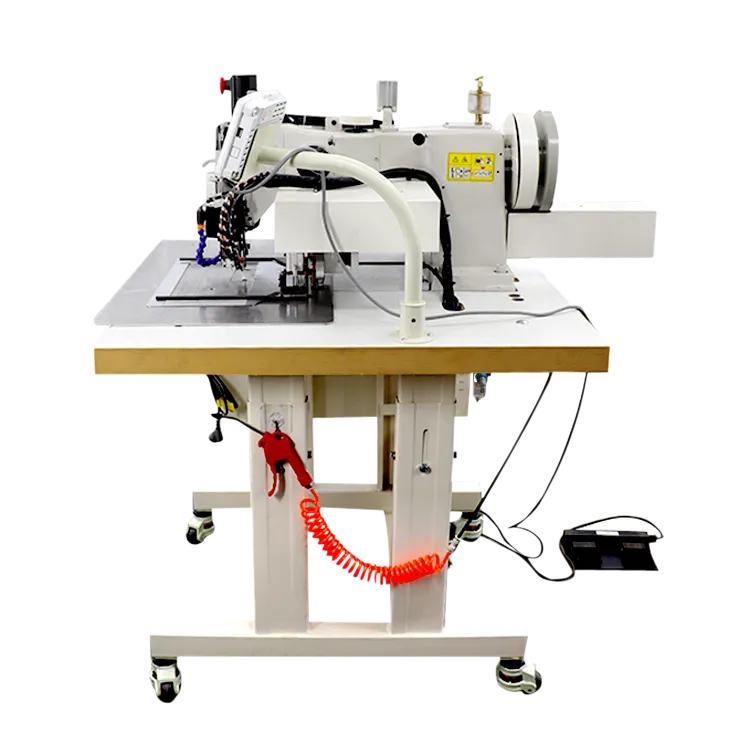

industrial sewing machine single needle

The Versatility of Single Needle Industrial Sewing Machines

In the fast-paced world of textile manufacturing and garment production, the choice of sewing equipment plays a pivotal role in ensuring quality, efficiency, and versatility. One of the most popular machines in the industry is the single needle industrial sewing machine. This machine has garnered significant attention due to its adaptability in various sewing applications, making it an essential tool for both small and large-scale operations.

Understanding Single Needle Industrial Sewing Machines

A single needle industrial sewing machine is specifically designed for high-speed sewing tasks, emphasizing precision and durability. Unlike its multi-needle counterparts, this machine utilizes a single needle, making it ideal for operations that require intricate stitching and detailed work. The simplicity of its design allows for easy handling and less complicated maintenance, appealing to a wide range of users, from small tailoring shops to large manufacturing facilities.

Key Features and Benefits

1. Precision and Quality One of the primary advantages of single needle machines is their ability to produce high-quality stitches. The consistent tension and precise needle movement ensure that seams are tight and uniform. This feature is particularly important in the garment industry, where the aesthetic quality of the final product is crucial.

2. Versatility Single needle industrial sewing machines are highly versatile, accommodating a wide variety of fabrics including lightweight materials like silk and heavier textiles like denim. This adaptability allows manufacturers to use a single machine for multiple projects, reducing the need for specialized equipment.

3. Speed and Efficiency Engineered for speed, these machines can sew at impressive rates, significantly increasing productivity in a manufacturing setting. The quick setup and straightforward threading process contribute to minimal downtime, allowing operators to focus on output without compromising quality.

4. Easy Maintenance The simplistic design of single needle machines often leads to easier maintenance compared to more complex multi-needle or computerized models. Fewer moving parts mean that operators can perform routine maintenance tasks, such as oiling and cleaning, more easily, which enhances the longevity of the machine.

industrial sewing machine single needle

Applications in the Industry

Single needle industrial sewing machines find applications across a range of sectors in the textile industry. They are commonly used in

- Garment Manufacturing From shirts to dresses, single needle machines handle a variety of stitching tasks, including hems, seams, and decorative stitching, ensuring that products meet retail standards. - Alterations and Tailoring Tailors appreciate the precision offered by single needle machines for alterations, allowing for adjustments that require a delicate touch and detail-oriented work.

- Upholstery and Home Decor The ability to stitch heavier fabrics makes these machines suitable for upholstery work, where strength and durability are required.

- Craft and Design Projects Many artisans and designers choose single needle machines for their individual projects, benefiting from the control and finesse these machines offer.

Conclusion

In the ever-evolving textile industry, the single needle industrial sewing machine remains a cornerstone of efficiency and quality. Its ability to produce precise, high-quality stitches at considerable speeds makes it invaluable to a range of sewing applications. Whether in a bustling factory or a small tailor shop, these machines enable operators to meet the demands of modern consumers, ensuring that the garments produced are not only functional but also aesthetically pleasing.

As technology continues to advance, the iconic single needle sewing machine will likely adapt and integrate new features while maintaining its fundamental advantages. For anyone involved in the textile manufacturing process, investing in a single needle industrial sewing machine presents an opportunity to enhance productivity and quality — key components in a competitive market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025