Competitive Pricing for Industrial Overlockers and Their Features Analysis

The Economics of Industrial Overlocker Prices An In-Depth Analysis

In the world of garment manufacturing, the importance of sewing machines cannot be overstated. Among these, industrial overlockers hold a special place due to their capability to deliver high-quality finishing on seams and edges, prevent fraying, and provide a professional touch to garments. As the demand for efficient and reliable sewing equipment rises, so too do questions surrounding the pricing of industrial overlockers. This article delves into the factors influencing the prices of these machines, offering insights into why they can vary widely and what this means for businesses in the textile industry.

Understanding Industrial Overlockers

Before exploring pricing, it’s essential to understand what an industrial overlocker is. Unlike standard sewing machines, overlockers, also known as sergers, function by trimming the fabric as they sew, resulting in a clean edge that is both functional and aesthetically pleasing. Typically used in mass production settings, they are prized for their speed, efficiency, and ability to work with multiple threads, creating strong, stretchable seams suitable for knit and woven fabrics alike.

Key Factors Influencing Prices

1. Brand Reputation and Quality Similar to other machinery, brand plays a significant role in determining price. Established brands with a reputation for durability and high performance typically command higher prices. Companies like Juki, Brother, and Bernina invest heavily in research and development, resulting in machines that often come with a higher price tag but offer enhanced reliability and longevity.

2. Machine Features and Technology Industrial overlockers come equipped with a variety of features that can significantly affect their price. Machines with advanced capabilities such as automatic tension adjustment, programmable stitch operations, and a higher number of threads tend to be priced higher. In contrast, basic models that offer limited functionality are generally more affordable and are suitable for smaller operations or beginners.

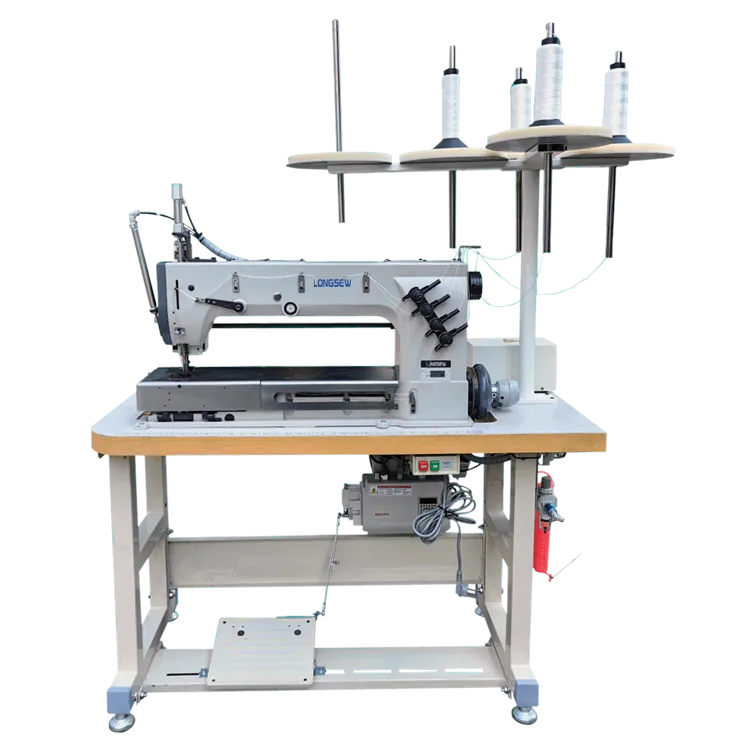

industrial overlocker prices

3. Production Capacity The capacity of an overlocker, typically measured in stitches per minute, is also a critical factor. Machines designed for high-volume production will generally cost more due to their robust construction and ability to handle continuous use without compromising stitch quality. For smaller businesses or home-based projects, investing in a high-capacity overlocker might not be necessary, thus influencing their purchasing decision.

4. Market Demand and Economic Conditions The pricing of industrial overlockers can also fluctuate based on market demand and economic conditions. During periods of economic growth, when fashion industries are booming, demand for sewing machines increases, often leading to higher prices. Conversely, in times of economic downturn, prices might become more competitive as manufacturers strive to maintain sales volume.

5. Maintenance and Warranty Services The costs associated with machine maintenance and the level of warranty support offered can also influence initial pricing. Machines that come with comprehensive support services often justify their higher cost by promising reduced long-term operational expenses through better maintenance and fewer breakdowns.

The Importance of Cost-Benefit Analysis

When considering the purchase of an industrial overlocker, businesses must perform a thorough cost-benefit analysis. This entails not just looking at the upfront costs but also assessing the long-term advantages of investing in a higher-quality machine. While a cheaper model might seem appealing, it could result in increased downtime and higher maintenance costs, negating any short-term savings.

Conclusion

Industrial overlocker prices reflect a multitude of factors ranging from brand reputation and machine capabilities to market conditions. Understanding these elements is crucial for businesses in the garment industry looking to invest wisely in equipment that will enhance their production capabilities. As with any investment, careful consideration of both initial costs and long-term benefits can lead to a decision that not only meets the immediate sewing needs of a business but also supports its growth and success in a competitive market. Whether a small workshop or a large manufacturing facility, understanding the nuances of industrial overlocker pricing can make all the difference in achieving operational efficiency and product quality.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025