fibc bag producing line

The Advancements in FIBC Bag Producing Lines

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags or big bags, have become an essential solution for transporting and storing bulk materials across various industries. The efficiency and effectiveness of these bags largely depend on the technological advancements in the FIBC bag producing line. As global demand for these containers continues to rise, manufacturers are investing in modernizing their production processes to enhance quality, reduce costs, and increase throughput.

A typical FIBC bag producing line comprises several key stages, including material preparation, weaving, cutting, sewing, and quality control. Each stage plays a crucial role in ensuring that the final product meets industry standards and customer requirements.

The Advancements in FIBC Bag Producing Lines

Once the raw materials are prepared, they undergo a weaving process. Modern FIBC bag producing lines utilize state-of-the-art looms that can produce fabrics with varying densities and weave patterns. Automated weaving machines not only enhance production speed but also ensure uniformity in the fabric, which is essential for maintaining the integrity of the bags during heavy loading conditions.

fibc bag producing line

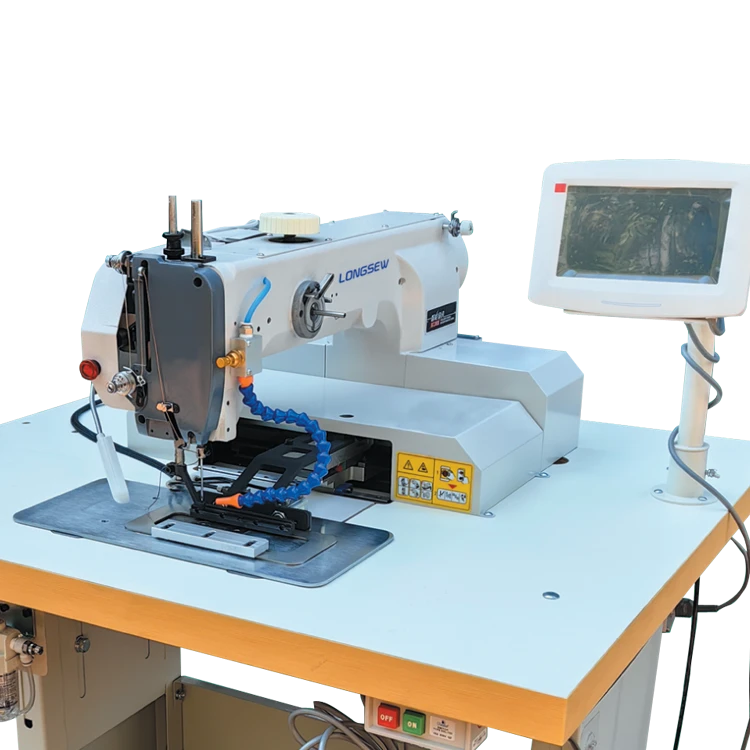

After weaving, the fabric is cut to the desired dimensions, and the bags are sewn together. High-speed sewing machines are employed to stitch the fabric securely, creating a reliable and robust product. Many manufacturers now incorporate smart technology into their sewing processes, allowing for real-time monitoring and adjustment, which leads to fewer defects and improved overall quality.

Quality control is another crucial aspect of the FIBC bag producing line. Automated inspection systems are increasingly used to identify any inconsistencies or flaws in the bags. These systems can detect issues such as seam strength and fabric integrity, ensuring that only bags meeting the stringent safety and quality standards make it to the market.

Moreover, the FIBC bag manufacturing industry has seen a shift towards eco-friendly production practices. Many producers are now focusing on sustainable materials and recyclable processes to meet the growing demand for environmentally responsible products. This trend not only helps reduce the ecological footprint of bulk bag production but also appeals to environmentally conscious consumers.

In conclusion, the evolution of FIBC bag producing lines has significantly improved the efficiency, quality, and sustainability of bulk bag production. As technology continues to advance, we can expect further innovations that will enhance the capabilities of FIBC bags, solidifying their role as a vital component in modern supply chains. With a commitment to quality and sustainability, manufacturers are well-positioned to meet the demands of a rapidly changing market.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025