fibc safety sewing

The Importance of Safety Sewing in FIBC Production

Flexible Intermediate Bulk Containers (FIBCs) have become the go-to solution for transporting bulk materials across various industries, including agriculture, pharmaceuticals, and construction. However, one critical aspect that ensures the reliability and safety of FIBCs is the quality of their sewing. Safety sewing not only guarantees the integrity of the container but also plays a significant role in preventing accidents and ensuring compliance with industry standards.

The Importance of Safety Sewing in FIBC Production

One of the primary safety considerations in FIBC sewing is the prevention of leaks and spills. A poorly sewn FIBC can lead to the escape of fine powders or granules, posing both environmental hazards and operational inefficiencies. As products like chemicals or food-grade materials are often transported in these containers, any breach could lead to contamination, financial loss, and legal liabilities. Therefore, ensuring that seams are properly aligned and secure is vital in maintaining the safety of the contained products.

fibc safety sewing

Moreover, adherence to international safety standards, such as those outlined by the FIBC Association and the ISO, is paramount. These regulations dictate the requirements for sewing techniques, materials, and testing procedures. Manufacturers must not only meet these standards but also continuously monitor and improve their sewing practices to adapt to evolving safety requirements. Regular inspections and thorough testing of the sewn seams help in identifying potential weaknesses before the containers are put into service.

Beyond technical specifications, it's essential to consider the training of personnel involved in the sewing process. Skilled workers who understand the implications of their craft can significantly enhance the safety and reliability of FIBCs. Investing in training programs ensures that employees are well-versed in the best practices for sewing and quality control.

In conclusion, safety sewing is a crucial aspect of FIBC production that must not be overlooked. By focusing on high-quality materials, employing advanced sewing techniques, adhering to safety standards, and training workers, manufacturers can produce FIBCs that are durable, safe, and effective for various applications. Ensuring the safety of these containers ultimately contributes to a more responsible and efficient supply chain, benefiting manufacturers and consumers alike.

-

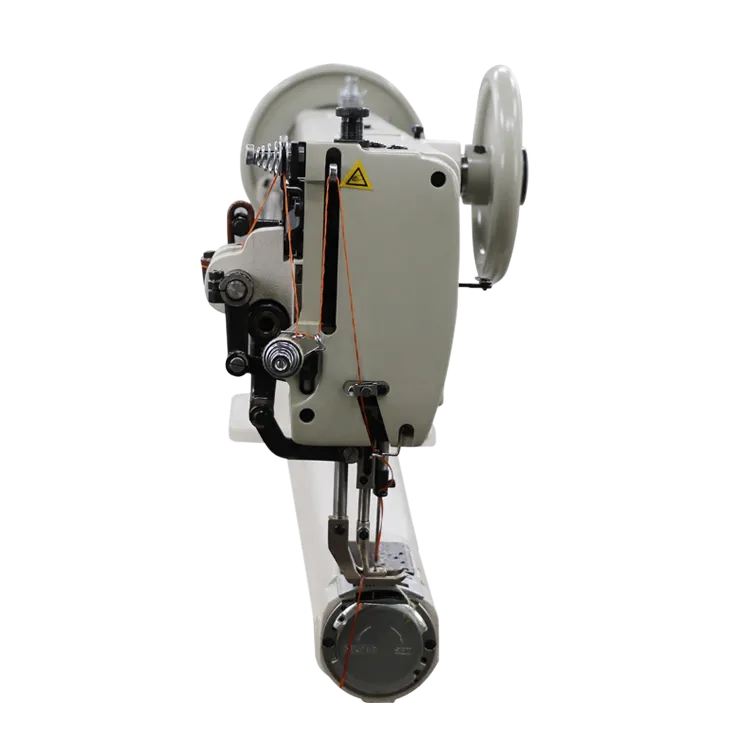

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025