double needle bar machine

The Double Needle Bar Machine Revolutionizing Textile Manufacturing

The world of textile manufacturing is an intricate landscape defined by continual evolution, driven by innovation and the quest for efficiency. One such innovative piece of equipment that exemplifies this evolution is the double needle bar machine. This remarkable machine has significantly enhanced the capabilities of textile production, enabling manufacturers to create complex and high-quality fabrics with remarkable precision.

What is a Double Needle Bar Machine?

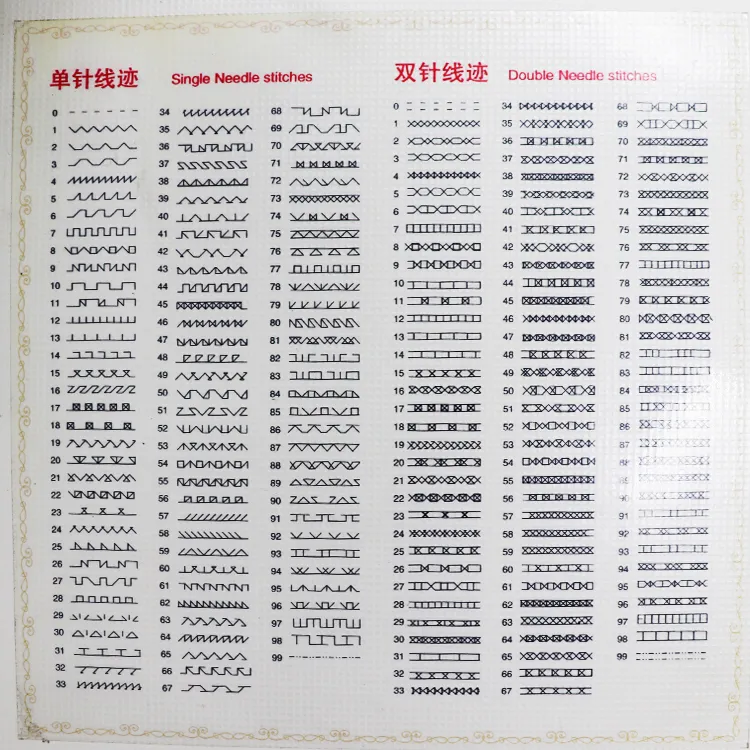

A double needle bar machine, also known as a double needle sewing machine, operates with two needles working simultaneously. This design allows for the creation of a wide range of stitch patterns, including two parallel rows of stitches, decorative designs, and intricate patterns that would be difficult or impossible to achieve with single needle machines. The dual needle system also provides stability to the fabric during sewing, reducing the risk of puckering—an issue often encountered in textile work.

Key Features and Advantages

1. Higher Productivity The double needle bar machine can significantly enhance productivity, particularly in operations requiring repetitive stitching tasks. Since it can sew two lines of stitches at once, manufacturers can achieve double the output in the same time frame compared to single needle machines.

2. Versatility One of the standout features of this machine is its versatility. It is suitable for various applications, including garment manufacturing, quilting, and home textiles. This adaptability makes it a valuable asset in any textile production environment, capable of addressing diverse customer needs without the need for multiple machines.

3. Quality of Stitching The ability to use two needles means that the machine can create multiple stitch types, which facilitates a better finish and enhances the aesthetic appeal of the final product. The consistency and quality of the stitches improve, resulting in more durable and visually pleasing textiles.

double needle bar machine

4. Cost-Effectiveness While the initial investment in a double needle bar machine may be higher than a traditional single needle machine, the long-term benefits often outweigh the costs. The increased productivity and quality can lead to higher profit margins, and the versatility of the equipment means that manufacturers can handle various projects without needing to invest in additional machines.

Applications in the Textile Industry

The double needle bar machine is widely utilized in various sectors of the textile industry. In apparel manufacturing, it is commonly used for sewing seams in trousers, shirts, and other garments, especially where durability and aesthetic appeal are critical. In the world of quilting, it allows for novel designs and intricate patterns that enhance the overall value of the finished product.

Furthermore, home textile manufacturers use double needle machines to produce quilts, bedspreads, and decorative pillows. The capacity to create complex patterns efficiently allows these manufacturers to meet consumer demands for unique and high-quality products without sacrificing production speed.

Future Trends and Technological Advancements

As technology continues to advance, the double needle bar machine is also evolving. Emerging technologies such as computer numerical control (CNC), automation, and enhanced software solutions are being integrated into these machines, offering improved precision, programmability, and ease of use. These advancements enable manufacturers to push the boundaries of creativity and efficiency in textile production even further.

In conclusion, the double needle bar machine stands as a testament to the ongoing innovation within the textile industry. Its ability to enhance productivity, versatility, and quality makes it an indispensable tool for manufacturers. As the industry continues to evolve, the importance of such technology will only grow, helping businesses meet the ever-increasing demands of consumers for high-quality, aesthetically pleasing textile products. Whether through enhanced functionality or the integration of cutting-edge technologies, the future of textile manufacturing is undoubtedly bright, with the double needle bar machine at its forefront.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025