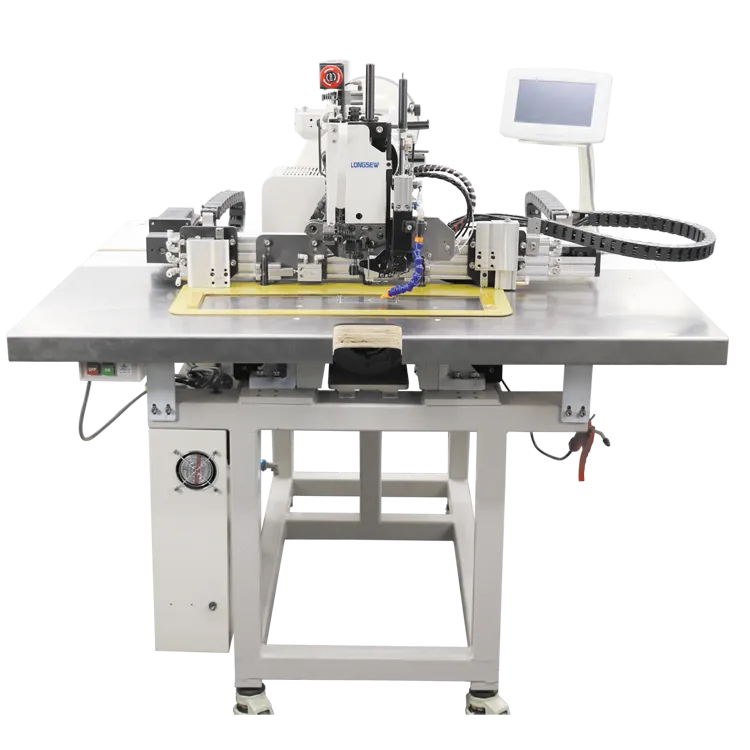

cnc upholstery sewing machine

Exploring CNC Upholstery Sewing Machines Revolutionizing Fabric Industries

In the ever-evolving landscape of manufacturing and crafting, the integration of technology has paved the way for enhanced precision, efficiency, and creativity. One of the standout innovations in this domain is the CNC upholstery sewing machine. This advanced piece of equipment is transforming the way upholstery is produced, combining traditional sewing techniques with modern, computerized technology to create intricate and detailed designs with unparalleled accuracy.

Understanding CNC Technology

CNC, or Computer Numerical Control, refers to the automated control of machining tools and 3D printers by a computer. The CNC upholstery sewing machine operates on similar principles, using computer algorithms to dictate the sewing process. This allows for intricate patterns and seams that would be nearly impossible to achieve manually. The integration of CNC technology means that manufacturers can produce high-quality upholstery in significantly less time, while also reducing the chances of human error.

Benefits of CNC Upholstery Sewing Machines

1. Precision and Consistency One of the primary advantages of using CNC upholstery sewing machines is the level of precision they offer. These machines can execute complex patterns with exact measurements, ensuring that every piece of furniture or fabric product is consistent. This precision is crucial for maintaining high standards in industries where quality is paramount.

2. Increased Production Speed CNC machines significantly increase the speed of production. Traditional sewing methods can be labor-intensive and time-consuming. In contrast, once a design is programmed into a CNC machine, it can reproduce that design repeatedly without the need for constant supervision. This accelerated production capability helps manufacturers meet tight deadlines and respond to market demands more effectively.

3. Design Flexibility With CNC technology, upholstery designers can push the boundaries of creativity. The software used to program these machines allows for the easy alteration of design parameters, enabling designers to experiment with new patterns and textures. This flexibility is particularly beneficial in a competitive market where uniqueness can set a product apart.

cnc upholstery sewing machine

4. Reduced Material Waste CNC upholstery sewing machines are designed to optimize fabric usage. By precisely controlling the cutting and sewing processes, these machines minimize the waste of materials, which not only helps the environment but also reduces costs for manufacturers. This efficiency is becoming increasingly important as eco-friendly practices gain traction in the industry.

5. User-Friendly Interfaces Modern CNC upholstery sewing machines come equipped with user-friendly interfaces that make programming and monitoring production a straightforward process. Many machines offer touchscreen controls and intuitive software that allows operators, even those with limited technical knowledge, to efficiently use the equipment.

Applications of CNC Upholstery Sewing Machines

CNC upholstery sewing machines have a wide range of applications in various sectors, including

- Furniture Manufacturing From sofas to chairs, the precision of CNC machines allows for intricate upholstery that enhances the aesthetic appeal of furniture. - Automotive Industry Customized interiors in cars, such as seats and dashboards, often rely on CNC sewing techniques to achieve the necessary fit and finish. - Marine Industry Upholstery for boats and yachts requires durable and weather-resistant materials, which CNC machines can handle with ease.

Conclusion

The advent of CNC upholstery sewing machines marks a significant transition in the textile and furniture industries. By marrying the art of sewing with cutting-edge technology, these machines are setting new standards for quality, efficiency, and creativity. As more manufacturers recognize the benefits of CNC technology, it is likely that this method will become the dominant force in upholstery production. The future holds exciting possibilities for designers and manufacturers alike, as they harness the power of CNC machines to create beautiful, functional, and innovative upholstered products. Embracing this technology isn't just a trend; it is a strategic move toward a more efficient and sustainable future in upholstery craftsmanship.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025