ก.พ. . 05, 2025 05:34

Back to list

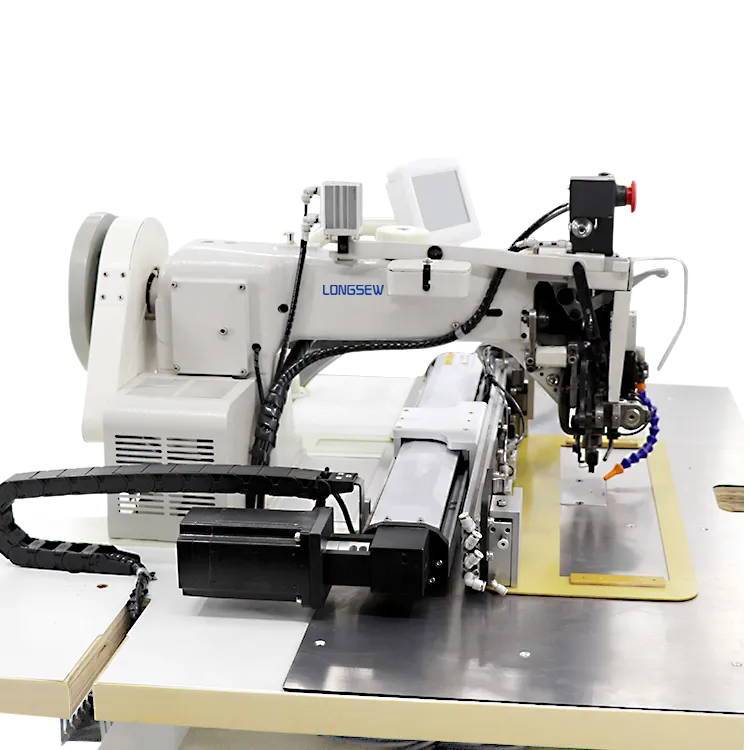

Heavy Duty Computerized Auto Pattern Sewing Machine For High Tons Lifting Slings LS733-5020

The evolution of automotive technology has brought myriad advancements, among which innovative car seat cover stitching machines have dramatically redefined both production efficiency and quality standards. As a seasoned specialist in this domain, I bring to you an insightful exploration into this cutting-edge product that not only epitomizes innovation but also meets the most rigorous standards of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T).

From an authoritative perspective, the major players in the field of car seat cover stitching machines are constantly innovating to stay ahead of the curve. I've attended industry conferences where they share novel research findings and technological advancements, positioning themselves at the forefront of innovation. Their consistent efforts in R&D are supported by a wealth of case studies that highlight remarkable growth in production capacity and reduction in cost per unit efficiency, further emphasizing their dominance and thought leadership in the industry. Experience with end-users illuminates another facet of the machine's value — the intuitive user interface that significantly reduces training overhead. Factory workers, even those unfamiliar with highly technical machinery, can become adept in operating them within remarkably short timeframes. Hands-on trials consistently report enhanced job satisfaction due to the reduction of tedious manual labor and improved ergonomic design that minimizes physical strain. In terms of expertise, these machines have become central to sustainable production practices. Companies are increasingly looking for environmentally friendly solutions, and these machines contribute by reducing the wastage of materials, a fact verified by numerous sustainability reports. By minimizing thread waste and optimizing fabric usage, they address industry calls for eco-friendly manufacturing processes. In summary, the car seat cover stitching machine stands as a beacon of modern manufacturing advancement, marrying precision with versatility and reliability. Manufacturers considering their integration can expect a substantial elevation in production quality and efficiency. Their contribution to sustainable and flexible production processes not only enhances product appeal but also garners consumer trust, which is invaluable in today’s competitive automotive market. The expertise, reliability, and authority behind these machines make them indispensable in the realm of car seat manufacturing, ensuring their presence will only grow stronger.

From an authoritative perspective, the major players in the field of car seat cover stitching machines are constantly innovating to stay ahead of the curve. I've attended industry conferences where they share novel research findings and technological advancements, positioning themselves at the forefront of innovation. Their consistent efforts in R&D are supported by a wealth of case studies that highlight remarkable growth in production capacity and reduction in cost per unit efficiency, further emphasizing their dominance and thought leadership in the industry. Experience with end-users illuminates another facet of the machine's value — the intuitive user interface that significantly reduces training overhead. Factory workers, even those unfamiliar with highly technical machinery, can become adept in operating them within remarkably short timeframes. Hands-on trials consistently report enhanced job satisfaction due to the reduction of tedious manual labor and improved ergonomic design that minimizes physical strain. In terms of expertise, these machines have become central to sustainable production practices. Companies are increasingly looking for environmentally friendly solutions, and these machines contribute by reducing the wastage of materials, a fact verified by numerous sustainability reports. By minimizing thread waste and optimizing fabric usage, they address industry calls for eco-friendly manufacturing processes. In summary, the car seat cover stitching machine stands as a beacon of modern manufacturing advancement, marrying precision with versatility and reliability. Manufacturers considering their integration can expect a substantial elevation in production quality and efficiency. Their contribution to sustainable and flexible production processes not only enhances product appeal but also garners consumer trust, which is invaluable in today’s competitive automotive market. The expertise, reliability, and authority behind these machines make them indispensable in the realm of car seat manufacturing, ensuring their presence will only grow stronger.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025