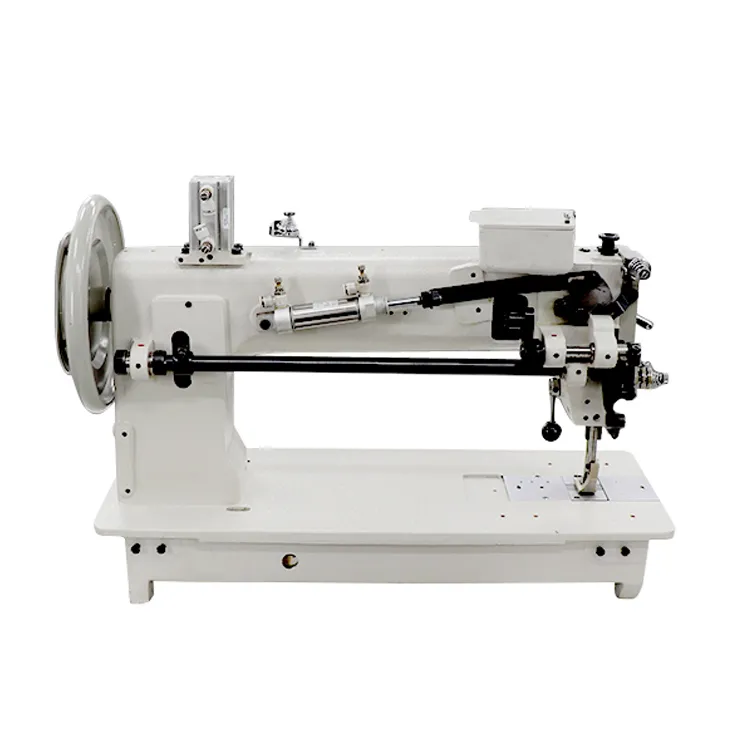

bobbinless lockstitch sewing machine

The Innovation of Bobbinless Lockstitch Sewing Machines

The evolution of sewing technology has led to significant advancements, one of which is the bobbinless lockstitch sewing machine. Traditionally, sewing machines required a bobbin to store thread, creating a dual-system that not only increased complexity but also maintenance demands. The introduction of bobbinless machines has revolutionized this aspect, streamlining the sewing process and enhancing productivity.

Bobbinless lockstitch sewing machines utilize a unique design that eliminates the need for a conventional bobbin. Instead of relying on the typical upper and lower thread systems, these machines employ advanced mechanisms that allow the upper thread to be fed directly from a spool. This innovative approach simplifies the threading process and reduces the time spent on reloading bobbins. As a result, garment manufacturers and tailors can significantly enhance their efficiency in completing sewing tasks.

One of the most appealing features of bobbinless machines is their ability to produce high-quality stitches consistently. The lockstitch mechanism ensures that the upper and lower threads intertwine perfectly, yielding a durable seam that can withstand the rigors of wear and tear. This level of reliability is crucial in industries looking to meet high standards for garment quality, and bobbinless machines deliver on that front.

bobbinless lockstitch sewing machine

Moreover, these machines contribute to a reduction in material waste. Traditional sewing machines often face issues with leftover threads from partially filled bobbins, leading to unnecessary waste. In contrast, bobbinless designs focus more on optimizing thread usage, allowing manufacturers to save on material costs and minimize their environmental impact.

The versatility of bobbinless lockstitch sewing machines cannot be overlooked. They are suitable for a wide range of fabrics, from lightweight materials to heavier textiles. This adaptability makes them ideal for various applications, including fashion apparel, upholstery, and technical textiles. As the demand for sustainable and efficient production processes grows, these machines play a vital role in meeting those needs.

In conclusion, the bobbinless lockstitch sewing machine represents a significant leap forward in textile manufacturing. By eliminating the bobbin, these machines streamline the sewing process, enhance stitch quality, reduce waste, and improve adaptability across different fabric types. As the industry continues to evolve, the adoption of such innovations will likely pave the way for more efficient, sustainable practices, ultimately benefiting manufacturers and consumers alike. The bobbinless lockstitch machine is not just a tool; it is a symbol of the future of sewing technology.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025