ม.ค. . 09, 2025 11:38

Back to list

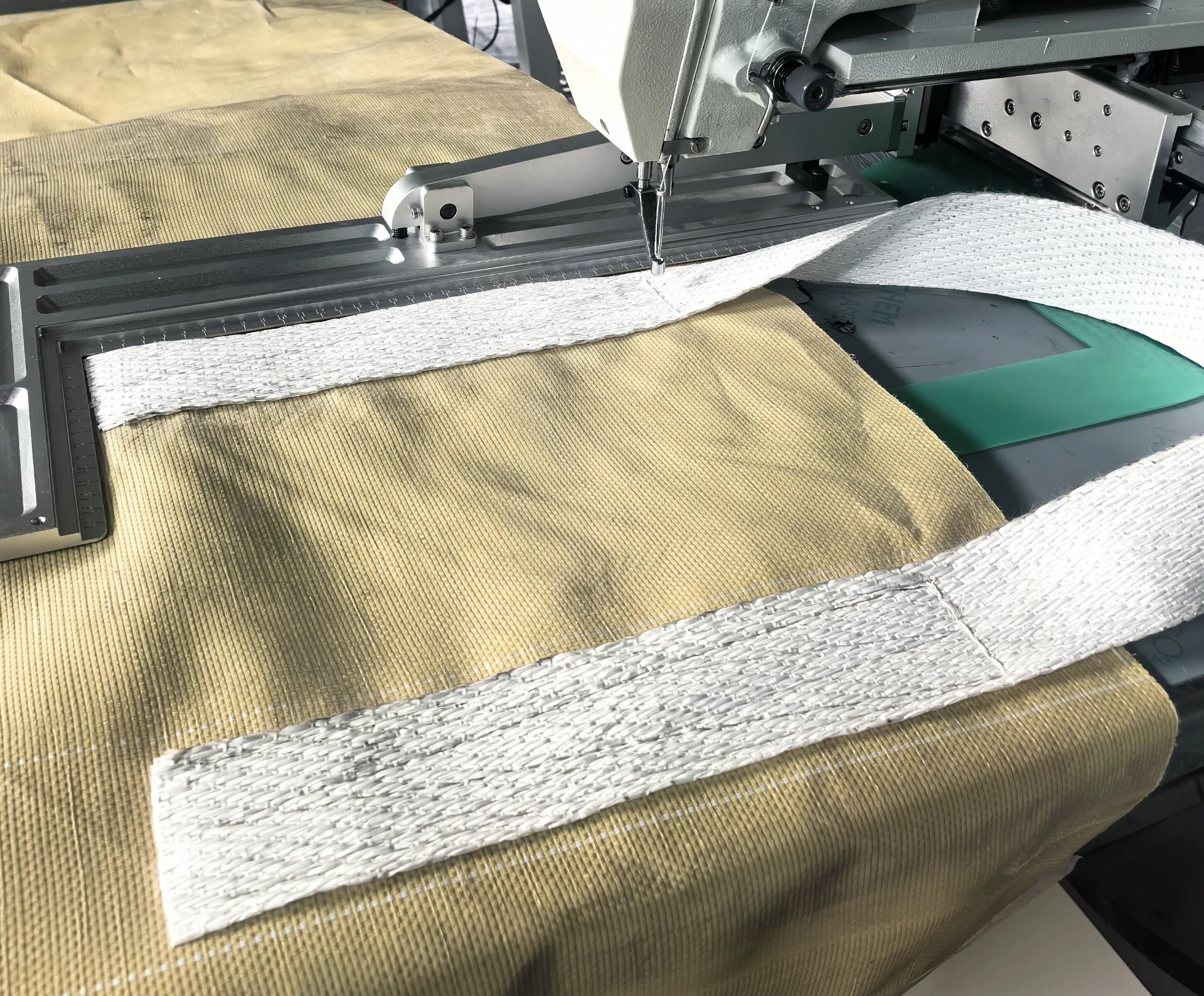

big bag sewing machine

Big bag sewing machines have revolutionized the packaging industry by providing an efficient and robust solution for handling large volumes of material. Imagine the traditional challenges of stitching hefty bags in industries like agriculture, manufacturing, and logistics. These machines offer the perfect blend of precision stitching, speed, and durability, which is essential for maintaining product integrity and ensuring seamless operations.

In terms of material compatibility, big bag sewing machines are adept at handling a wide range of bags, from synthetic fabrics like polypropylene to natural fibers. This versatility is vital for industries that deal with diverse materials. Operators should consult the machine’s specifications to guarantee that it supports the required fabric types, thereby optimizing performance and prolonging the equipment's lifespan. Integrating a big bag sewing machine into existing production lines can be a strategic move to boost capacity while maintaining product quality. Many organizations that have adopted these machines report smoother operations and enhanced brand reputation due to the consistency and durability of the stitched products. They are seen as an investment, with the return manifesting in the form of reduced labor costs, increased throughput, and fewer product defects. Finally, it’s crucial to evaluate technological advancements such as IoT compatibility and data analytics features in modern sewing machines. These additions allow for real-time monitoring of operational parameters, predictive maintenance insights, and seamless integration with other smart factory systems. By leveraging such capabilities, companies can maintain a competitive edge and adapt to the ever-evolving demands of the market. Choosing the right big bag sewing machine involves a confluence of experience, expertise, authority, and trust. It’s about finding a machine that not only meets current needs but also accommodates future growth. As industries progress, these machines will continue to play a pivotal role in enhancing productivity and quality within the packaging and materials handling sectors.

In terms of material compatibility, big bag sewing machines are adept at handling a wide range of bags, from synthetic fabrics like polypropylene to natural fibers. This versatility is vital for industries that deal with diverse materials. Operators should consult the machine’s specifications to guarantee that it supports the required fabric types, thereby optimizing performance and prolonging the equipment's lifespan. Integrating a big bag sewing machine into existing production lines can be a strategic move to boost capacity while maintaining product quality. Many organizations that have adopted these machines report smoother operations and enhanced brand reputation due to the consistency and durability of the stitched products. They are seen as an investment, with the return manifesting in the form of reduced labor costs, increased throughput, and fewer product defects. Finally, it’s crucial to evaluate technological advancements such as IoT compatibility and data analytics features in modern sewing machines. These additions allow for real-time monitoring of operational parameters, predictive maintenance insights, and seamless integration with other smart factory systems. By leveraging such capabilities, companies can maintain a competitive edge and adapt to the ever-evolving demands of the market. Choosing the right big bag sewing machine involves a confluence of experience, expertise, authority, and trust. It’s about finding a machine that not only meets current needs but also accommodates future growth. As industries progress, these machines will continue to play a pivotal role in enhancing productivity and quality within the packaging and materials handling sectors.

Previous:

Next:

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025