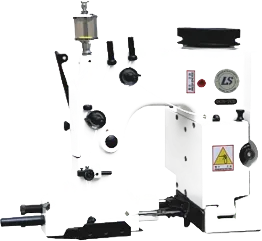

bag closer machine double needle

The Double Needle Bag Closer Machine An Essential Tool in Packaging

In the fast-paced world of manufacturing and packaging, efficiency and precision are paramount. One of the unsung heroes in this sector is the double needle bag closer machine, a remarkable tool designed to streamline the process of sealing bags. Whether in food production, agriculture, or industrial sectors, these machines play a critical role in ensuring that products are securely packaged and safeguarded from contamination.

Functionality and Design

The double needle bag closer machine utilizes two needles to stitch bags shut, creating a sturdy and secure closure. This design not only contributes to the integrity of the package but also enhances its aesthetic appeal. Typically operated with heavy-duty threads, these machines are capable of sealing various types of bags, including those made from woven polypropylene, paper, and even some plastic materials.

The design of the double needle system allows for a more even distribution of tension across the seam, which is particularly important for bags that will hold heavy or bulk materials. Traditional single needle machines may struggle under such conditions, leading to weak points that can result in spills and product waste. By contrast, the twin needle approach enhances durability, making it an ideal solution for industries where reliability is a must.

Benefits of Using a Double Needle Bag Closer

1. Enhanced Strength The dual stitching provides increased seam strength, ensuring that bags can withstand handling, storage, and transportation without compromising their contents.

bag closer machine double needle

2. Efficiency Modern double needle bag closer machines are equipped with various automation features. Operators can achieve high-speed stitching, drastically reducing the time taken to seal bags compared to manual methods or single needle machines.

3. Versatility These machines can accommodate bags of different sizes and materials, making them suitable for diverse applications. From agricultural products like grains and seeds to industrial items such as chemicals and parts, the double needle bag closer machine proves its adaptability across sectors.

4. Consistency Consistency in product sealing is crucial for quality control. The double needle system ensures that every bag is sewn with precision, reducing the risk of production errors that could lead to financial losses or compromised product quality.

5. Labor Savings Automation and efficient design mean that fewer workers are needed to operate the machines. This not only reduces labor costs but also minimizes the risk of workplace injuries associated with manual sealing processes.

Conclusion

As industries continue to evolve, the demand for efficient and reliable packaging solutions grows. The double needle bag closer machine stands out as a vital asset in achieving these goals. By enhancing bag strength, improving efficiency, and ensuring consistency, these machines contribute significantly to the economic viability of packaging operations.

In a world where first impressions matter, the packaging often serves as the face of the product. A well-sealed bag not only protects the contents but also reflects the quality and standards of the manufacturer. As businesses strive to meet consumer expectations and regulatory requirements, investing in a double needle bag closer machine becomes not just a choice but a strategic necessity for any company serious about maintaining its competitive edge in the marketplace.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025