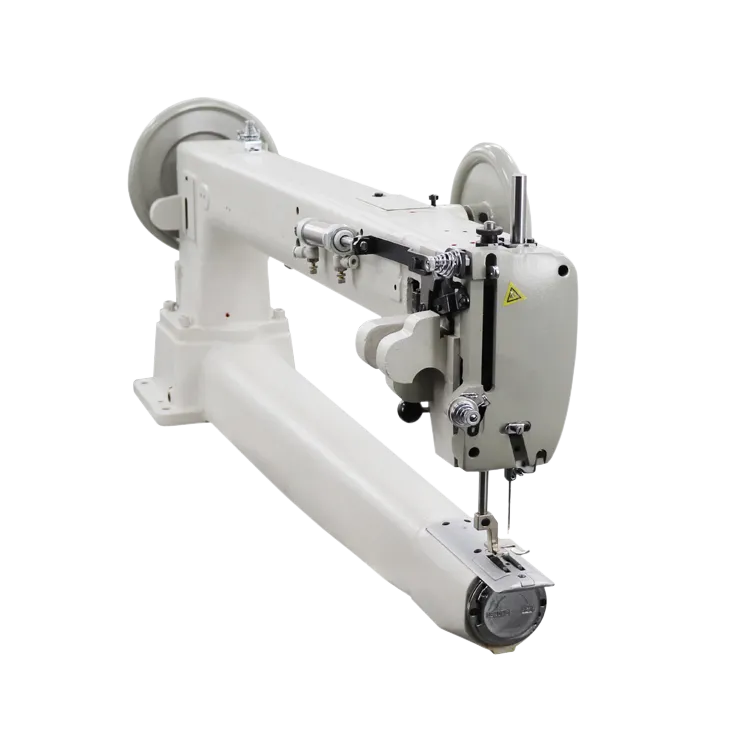

automotive upholstery sewing machine

The Evolution of Automotive Upholstery Sewing Machines

The automotive industry is ever-evolving, and with it, the technology that supports its intricate processes. Among these technologies, automotive upholstery sewing machines play a vital role. These machines are essential for crafting the interiors of vehicles, ensuring both aesthetics and functionality. Let’s delve into the evolution of these machines, their significance in car manufacturing, and the technological advancements that have reshaped the industry.

The Significance of Upholstery in Automotive Design

Automotive upholstery encompasses all aspects of a vehicle's interior, from seats and door panels to headliners and floor mats. The quality of upholstery significantly impacts the overall perception of a vehicle. Today's consumers demand higher levels of comfort, durability, and style. As a result, manufacturers must employ advanced sewing techniques and equipment to meet these expectations. Automotive upholstery sewing machines are crucial for creating high-quality products that withstand wear and tear while providing a visually appealing finish.

Historical Perspective

The journey of automotive upholstery sewing machines began in the early 20th century when the first mass-produced cars emerged. Initially, sewing was done manually, which was a labor-intensive process. As the automotive sector grew, so did the need for more efficient production methods. In the 1920s and 1930s, sewing machines began to be adapted for use in the automotive industry, allowing for quicker assembly and more consistent results.

With the advent of World War II, the demand for mass production led to significant innovations. Manufacturers sought more efficient sewing machines to keep pace with the growing automotive market. The introduction of electric sewing machines marked a turning point, enabling more versatile and speedy operations.

Modern Automotive Upholstery Sewing Machines

Today’s automotive upholstery sewing machines are sophisticated, featuring advanced technology that enhances their efficiency and effectiveness. These machines often include features like automatic threading, programmable stitch patterns, and heavy-duty capabilities to handle various materials, from leather to synthetic fabrics.

automotive upholstery sewing machine

One of the most notable advancements is the integration of computer numerically controlled (CNC) technology. CNC upholstery sewing machines can replicate complex designs and patterns with precision that manual sewing simply cannot achieve. Additionally, automation has reduced production times and errors, resulting in cost savings and improved product quality.

Moreover, many modern machines are equipped with specialized attachments and tools designed for specific tasks, such as piping, embroidery, or quilting. These features allow manufacturers to add unique design elements to vehicle interiors, catering to consumer preferences for customization and luxury.

Environmental Considerations and Sustainability

With the increasing focus on sustainability and eco-friendliness, automotive upholstery sewing machines are also adapting to green initiatives. Manufacturers are now using recyclable materials and eco-friendly processes in their upholstery solutions. Innovative technologies are being developed to minimize waste and reduce energy consumption during the production process.

Additionally, advancements in fabric technology have led to the creation of sustainable upholstery materials, such as recycled polyester and organic cotton. These materials not only meet aesthetic demands but also resonate with environmentally conscious consumers.

Conclusion

Automotive upholstery sewing machines have come a long way from their humble beginnings in the early days of the automotive industry. Their evolution has been driven by the need for efficiency, precision, and quality in a competitive market. As technology continues to advance, these machines will undoubtedly evolve further, incorporating smart technology and sustainable practices that align with the automotive industry's future.

In conclusion, automotive upholstery sewing machines are indispensable tools in creating the interiors that define the character of vehicles. As manufacturers and consumers alike turn their attention to quality, sustainability, and innovation, these machines will remain at the forefront of automotive design, ensuring that the interiors of tomorrow meet the demands of a new generation of drivers.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025