Exploring the Features and Benefits of 2% Needle Sewing Machines for Efficient Stitching

The Importance of Needle Sewing Machines in Modern Textile Production

In the rapidly evolving world of textile production, the needle sewing machine has remained a foundational tool for manufacturers and artisans alike. The functionality and versatility of these machines are critical, whether in large-scale garment factories or small craft workshops. Among the many types of sewing machines available, the 2% needle sewing machine stands out for its unique applications and benefits.

The 2% needle sewing machine typically refers to machines that can use two needles simultaneously, often allowing for decorative stitching or the attachment of multiple fabric layers. This machine is a game changer for the production of high-quality textiles, enabling the creation of intricate patterns that enhance the aesthetic appeal of garments and other fabric products.

Enhanced Efficiency and Productivity

One of the primary reasons for the adoption of the 2% needle sewing machine is its ability to streamline the sewing process. By using two needles, operators can complete tasks that would traditionally require multiple passes with a single needle sewing machine. This efficiency translates into reduced production time, allowing manufacturers to meet tight deadlines and increase their output without compromising quality. In a sector where time often equates to money, the 2% needle sewing machine becomes an essential asset.

Versatility in Design

The 2% needle sewing machine is not only about speed; it also opens up opportunities for creative design. Fashion designers and textile artists can incorporate more complex stitching techniques into their work. The ability to layer fabrics and create decorative seams provides endless possibilities for creating unique garments and textiles. This versatility ensures that manufacturers can cater to diverse customer preferences, from simple everyday wear to elaborate fashion statements, thus broadening their market reach.

Durability and Stability

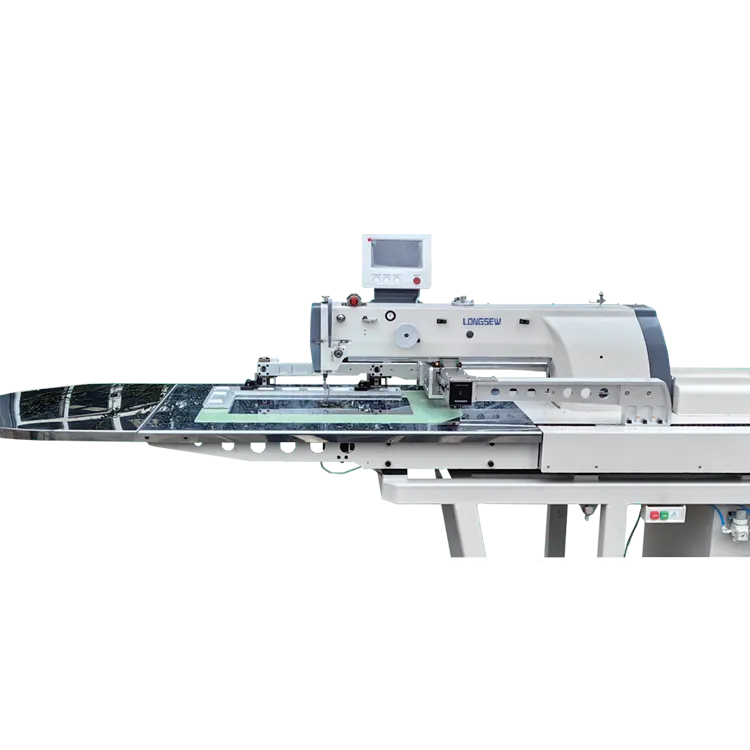

2 needle sewing machine

Another significant advantage of the 2% needle sewing machine is the enhanced durability and stability of the seams it produces. Two needles working in tandem can distribute tension more evenly across the fabric, resulting in stronger seams that are less likely to fray or break under stress. This durability is crucial for items subjected to wear and tear, such as workwear or outerwear. Ultimately, higher-quality products lead to greater customer satisfaction and brand loyalty.

Sustainability Efforts

In an era where sustainability is a critical consideration for both producers and consumers, the 2% needle sewing machine also aligns with eco-friendly practices. By enhancing the efficiency of the sewing process and reducing waste—through the capability to stitch layers or decorative elements in a single pass—manufacturers can minimize their resource consumption. This alignment with sustainable practices not only appeals to environmentally conscious consumers but also helps businesses lower costs and improve their bottom line.

User-Friendly Technology

Modern advancements in technology have made the operation of 2% needle sewing machines more user-friendly. Features like digital displays, automatic needle positioning, and programmable settings allow operators to work efficiently and reduce human error. These technological enhancements ensure that even those with limited sewing experience can quickly adapt to using these machines, thereby expanding their accessibility within the industry.

Conclusion

In summary, the 2% needle sewing machine plays a vital role in the textile production landscape. Its efficiencies in manufacturing, creative versatility, seam durability, sustainability potential, and user-friendly advancements make it an invaluable tool for both mass production and artisan projects. As the textile industry continues to evolve, the importance of such innovative sewing technology cannot be overstated, ensuring that it remains a cornerstone of quality craftsmanship in fabric production. Whether for creating the latest fashion trends or durable everyday wear, the 2% needle sewing machine will undoubtedly continue to make its mark on the industry for years to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025