High-Performance 2% Needle Industrial Sewing Machine for Efficient Textile Production

The Versatility of the 2 Needle Industrial Sewing Machine

In the world of textile manufacturing, the choice of sewing machines plays a crucial role in determining the efficiency and quality of the output. Among the various types available, the 2 needle industrial sewing machine has gained considerable attention for its unique capabilities. This machine, designed for mass production, offers significant advantages in terms of versatility, precision, and speed.

The Versatility of the 2 Needle Industrial Sewing Machine

One of the primary advantages of the 2 needle industrial sewing machine is its speed. Industrial sewing machines are designed specifically for high-volume production, and the 2 model is no exception. Capable of functioning at remarkable speeds, these machines can significantly reduce production times, resulting in increased output for manufacturers. This speed provides a competitive edge, enabling businesses to meet tight deadlines while maintaining quality standards.

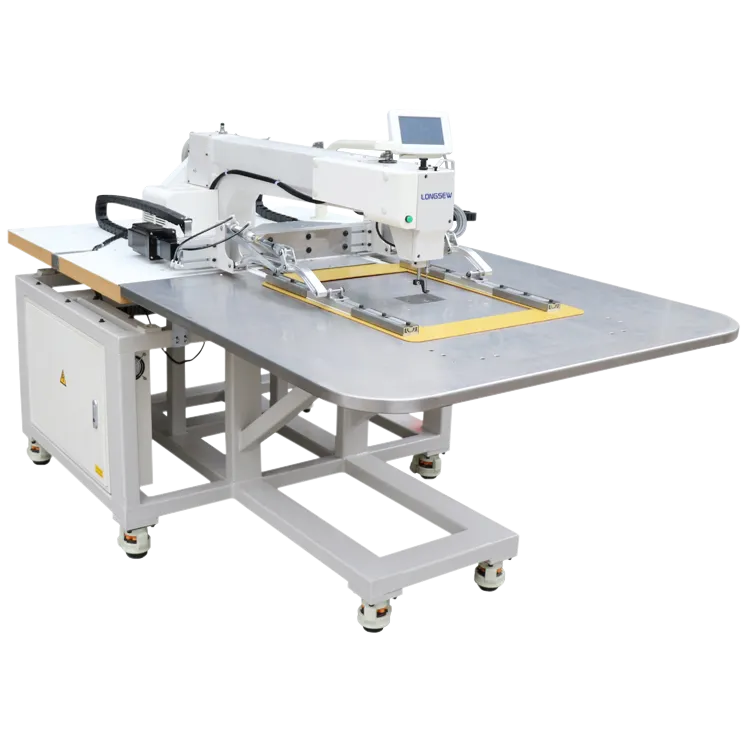

2 needle industrial sewing machine

Precision is another key feature of the 2 needle sewing machine. The synchronized movement of the two needles, combined with advanced feed mechanisms, ensures that fabric layers are aligned perfectly. This precision is vital, especially when working with intricate designs or multiple fabric layers, as it minimizes the likelihood of errors and defects in the finished product. For industries where every stitch counts, such as fashion design and technical textiles, the accuracy offered by this machine is indispensable.

The versatility of the 2 needle industrial sewing machine extends beyond just the types of stitches it can create. It is compatible with a wide range of fabrics, from lightweight materials to heavy canvas. This adaptability makes it a popular choice among manufacturers who work with diverse textiles. Whether sewing delicate lace for evening wear or robust fabrics for outdoor gear, the 2 needle machine can be easily adjusted to accommodate different thicknesses and textures.

Moreover, many modern 2 needle industrial sewing machines come equipped with advanced features such as computerized controls, programmable settings, and automatic thread trimming. These enhancements further streamline the sewing process, allowing for greater efficiency and ease of use. Operators can quickly switch between different tasks, and the automated functions reduce the manual labor required, minimizing fatigue and the risk of errors.

In conclusion, the 2 needle industrial sewing machine stands out as a powerful tool in the textile manufacturing industry. Its ability to combine speed, precision, and versatility makes it an essential asset for businesses looking to enhance their production capabilities. As technology continues to advance, the capabilities of these machines will only improve, solidifying their place as a cornerstone in the world of industrial sewing. For manufacturers aiming to achieve high-quality results in a timely manner, investing in a 2 needle industrial sewing machine is a decision that promises substantial returns.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025