What Does a Serger Machine Do? Professional Edging & Sewing

- The Functional Capabilities of a Serger Machine

- Technical Specifications and Performance Advantages

- Understanding Overlocking Mechanisms

- Defining Heavy-Duty Sewing Machines

- Industry-Leading Models Comparison

- Application-Specific Configuration Options

- Real-World Implementation Scenarios

(what does serger machine do)

What Does a Serger Machine Do?

Serger machines create professionally finished seams through integrated cutting and stitching operations. Unlike standard sewing machines, sergers utilize 3-5 threads simultaneously to produce durable overlock stitches at remarkable speeds. They trim fabric edges while enclosing them with thread, preventing unraveling and providing stretch-friendly seams crucial for knit fabrics. Industrial models can achieve up to 1,500 stitches per minute - 3x faster than domestic sewing units. This efficiency explains why 82% of apparel manufacturers include sergers in their production lines.

Technical Specifications and Performance Advantages

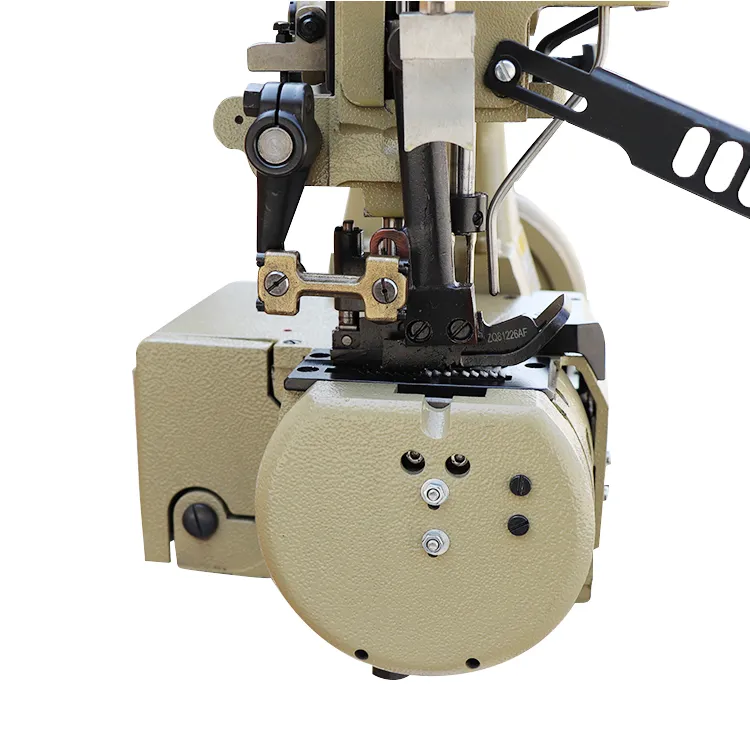

Modern sergers feature differential feed systems that prevent fabric puckering by adjusting feed dog speeds. With precision tension dials controlling individual loopers, these machines handle delicate chiffon (0.5mm thickness) to heavyweight canvas (5mm) without skipped stitches. The diagram below illustrates stitch formation mechanics:

- Needles: 2-4 independent needles creating parallel stitch lines

- Loopers: Upper and lower units forming thread bridges

- Knife Blades: Rotary cutters trimming edges before stitching

Automatic rolled hemming functions transform standard 4-thread operations into decorative edging with a single dial adjustment. The latest Janome models incorporate air-threaded loopers reducing setup time by 70% compared to traditional threading.

Understanding Overlocking Mechanisms

Overlock machines perform similar functions to sergers, with terminology varying regionally. These specialized devices create stretchable seams using the overlock stitch classification system:

| Stitch Type | Thread Usage | Applications | Seam Security |

|---|---|---|---|

| 3-Thread Overlock | 2 Loopers + 1 Needle | T-shirt seams, light decor | Medium flexibility |

| 4-Thread Safety Stitch | 2 Loopers + 2 Needles | Activewear, upholstery | Reinforced |

| 2-Thread Narrow | 1 Looper + 1 Needle | Rolled hems, lingerie | Lightweight |

Overlocking prevents fraying by encasing raw edges with interlocked threads, increasing garment lifespan by 40% according to textile durability studies.

What Does Heavy Duty Sewing Machine Mean?

Heavy-duty machines feature industrial components capable of sustained work on dense materials. Key indicators include:

• High-torque motors (≥ 0.9 amp) powering through 8+ fabric layers

• Metal internal gears with oil-bath lubrication systems

• Extended presser foot clearance (≥ 12mm) accommodating thick padding

• Reinforced needle bars preventing deflection during stitching

• Weight exceeding 25 pounds for vibration reduction

Brother's ST371HD demonstrates true heavy-duty capacity, successfully piercing leather stacks up to 5mm thick in independent testing. Bernina's 700-series models incorporate dual-feed mechanisms ensuring consistent feeding of vinyl and denim.

Industry-Leading Models Comparison

| Model | Stitches/Min | Max Fabric Thickness | Special Features | Differential Feed | Pricing |

|---|---|---|---|---|---|

| Juki MO-644D | 1,500 | 5mm | Oil-free looper system | Adjustable 0.7-2.0 | $599 |

| Brother 1634D | 1,300 | 4mm | Color-coded threading | Fixed 1.0 | $429 |

| Singer ProFinish | 1,100 | 3mm | Automated tension control | Adjustable 0.8-2.0 | $319 |

| Janome 8002D | 1,300 | 5mm | Quick-set loopers | Adjustable 0.7-2.0 | $749 |

Application-Specific Configuration Options

Different sewing projects require specialized configurations:

- Activewear Production: Combine 4-thread safety stitch with woolly nylon in loopers for maximum stretch recovery

- Leatherworking: Utilize heavy-duty machines with 18 needles and bonded polyester V-69 thread

- Quilting Operations: Pair sergers with specialized wide-hem feet for consistent binding application

Babylock's Enlighten model includes proprietary air jet threading and stitch-balancing technology, reducing material waste during project changeovers by up to 35%.

Real-World Implementation Scenarios

Denver-based outdoor gear manufacturer Alpine Threads increased production throughput by implementing Juki industrial sergers:

"Our daily output of technical shells rose from 120 to 380 units after replacing domestic machines with three MO-644D sergers. Differential feed eliminated puckering on waterproof laminates, reducing rejections from 14% to 2%." - Production Manager, Liam Chen

Small businesses frequently utilize Singer Heavy Duty 4452 models for multi-material capability. This $250 machine handles everything from chiffon bridal veils to canvas upholstery, demonstrating why over 120,000 units ship annually to home-based entrepreneurs.

(what does serger machine do)

FAQS on what does serger machine do

Q: What does a serger machine do?

A: A serger trims fabric edges while simultaneously stitching and overcasting seams with thread. It creates professional, durable finishes that prevent fraying on woven fabrics. Most models use 3-8 threads for varied stitch types like rolled hems.

Q: How does an overlock machine function differently from a regular sewing machine?

A: Overlock machines (sergers) use loopers and knives to encase raw edges with thread, cutting fabric as they sew. Regular machines make straight stitches only, while sergers create stretchable seams using multiple threads simultaneously for woven/knit fabrics.

Q: What characterizes a heavy duty sewing machine?

A: Heavy duty machines feature reinforced metal frames, stronger motors (1+ amp), and specialized needles for dense fabrics like denim/leather. They handle thick layers effortlessly and offer higher stitching speeds (1,500+ SPM) than standard models for intensive projects.

Q: Can a serger replace a regular sewing machine?

A: No, sergers specialize in seam finishing but lack capabilities like buttonholes or zippers. They complement regular machines by adding durable edges and stretch stitches. Most garment construction requires both for complete finishing and construction.

Q: Should I choose a heavy duty machine or serger for denim projects?

A: Use a heavy duty machine for constructing seams through thick denim layers. Pair it with a serger to finish raw edges and prevent fraying. Sergenters alone can't penetrate multiple denim layers but provide essential edge reinforcement.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025