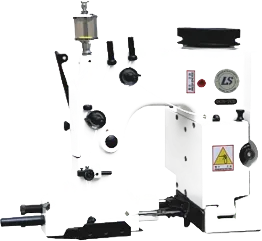

Single Needle Lockstitch Sewing Machine for Precision and Versatility in Textile Projects

The Single Needle Lockstitch Sewing Machine An Essential Tool in Textile Production

The single needle lockstitch sewing machine is a pivotal piece of equipment in the textile and garment industry. Renowned for its simplicity and efficiency, this machine plays a crucial role in producing high-quality stitched products ranging from clothing to home furnishings. Understanding its functionality, advantages, and applications can provide valuable insights into its indispensable role in modern sewing operations.

At its core, the single needle lockstitch sewing machine operates on a straightforward mechanism that employs a single needle and two threads—one coming from the spool and the other from a bobbin located beneath the needle plate. As the needle penetrates the fabric, it creates a loop with the upper thread, which is then interlaced with the lower thread from the bobbin, forming a secure lockstitch. This method not only ensures that the stitches are tight and uniform but also contributes to the durability of the seams produced.

One of the primary advantages of the single needle lockstitch machine is its versatility. It can sew a variety of materials, from lightweight fabrics like cotton and silk to heavier materials such as denim and canvas. This adaptability makes it a valuable asset for small-scale tailors as well as large-scale manufacturers. Moreover, it is designed for a range of sewing applications, including straight stitching, zigzag stitching, and even decorative stitching, enabling producers to fulfill diverse design requirements.

single needle lockstitch sewing machine

The single needle lockstitch sewing machine is also celebrated for its precision and speed

. Advanced models are equipped with features such as automatic thread cutting, adjustable stitch length, and speed control, enhancing usability and efficiency. Additionally, the design of the machine minimizes fabric puckering, ensuring that the finished products maintain a polished appearance. This precision is particularly essential in high-stakes industries such as fashion design, where the quality of seams can significantly impact the garment's aesthetic and structural integrity.Maintenance is another critical aspect of the single needle lockstitch machine. Regular upkeep, such as oiling the machine, cleaning out dust and lint, and checking for wear and tear, is essential to ensure optimal performance and longevity. Proper maintenance not only prolongs the life of the machine but also ensures consistent sewing quality, which is vital in meeting production demands.

In recent years, the industry has witnessed innovations in sewing technology, leading to the development of computerized single needle lockstitch machines. These modern machines offer advanced features such as programmable patterns and automatic tension adjustments, elevating sewing operations to new levels of efficiency and creativity.

In conclusion, the single needle lockstitch sewing machine remains a cornerstone of the textile industry. Its simplicity, versatility, and efficiency make it an essential tool for anyone involved in sewing, from hobbyists to industrial manufacturers. As technology continues to advance, this classic machine is poised to adapt and thrive, ensuring that it remains relevant in an ever-evolving marketplace. Embracing both traditional techniques and modern innovations, the single needle lockstitch sewing machine will continue to shape the future of garment production.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025