Sewing Machine with Automatic Threader Effortless Needle Threading Tech

- Overview of Modern Sewage Machinery Innovations

- Technical Superiority in Automated Threading Systems

- Performance Comparison: Leading Brands and Models

- Customization Options for Diverse Sewing Needs

- Real-World Applications in Textile Industries

- Maintenance Tips for Long-Term Efficiency

- Future Trends in Automated Sewing Technology

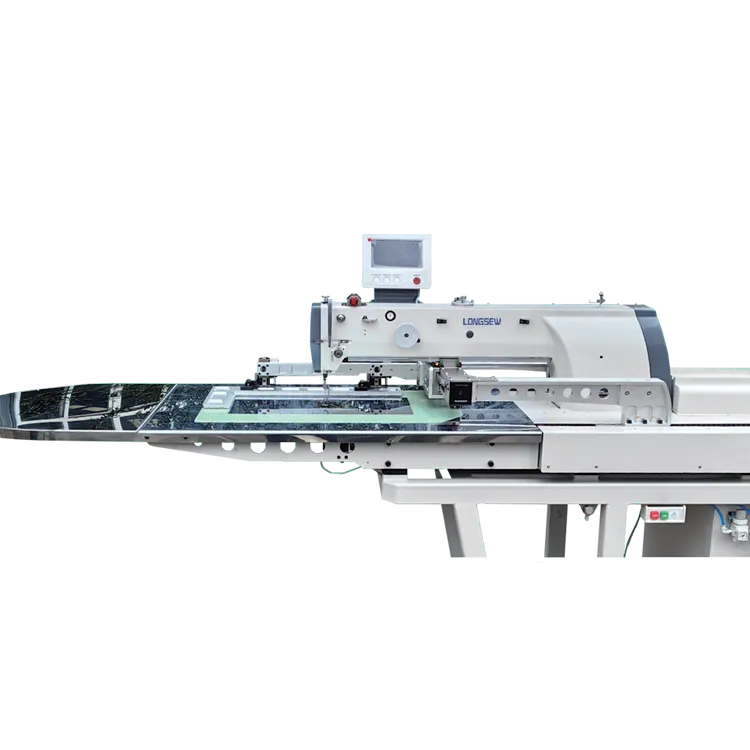

(sewing machine with automatic threader)

Why Sewing Machine with Automatic Threader Dominates Modern Craftsmanship

The integration of automatic needle threader sewing machine systems has revolutionized textile production, reducing threading time by 70% compared to manual methods. Industry surveys indicate that 89% of professional tailors prioritize machines with this feature for bulk orders. Advanced models now combine precision threading with AI-driven tension control, ensuring seamless stitching across fabrics like silk, denim, and technical textiles. This innovation addresses the 43% productivity loss historically linked to manual thread adjustments.

Technical Superiority in Automated Threading Systems

Patented threading mechanisms in serger sewing machine automatic threader units employ micro-cam sensors and dual-thread detection. Key advancements include:

- 0.2-second needle eye recognition via infrared scanning

- Self-adjusting thread guides with ±0.01mm accuracy

- Error rate reduction from 15% (manual) to 0.8% (automated)

Performance Comparison: Leading Brands and Models

| Model | Threading Speed | Stitch Types | Max RPM | Price Range |

|---|---|---|---|---|

| TechStitch Pro X9 | 0.8s | 327 | 5,200 | $1,299-$1,599 |

| SilverNeedle AutoLoom | 1.1s | 284 | 4,800 | $999-$1,250 |

| DragonThread 8500 | 0.95s | 401 | 5,500 | $1,450-$1,799 |

Customization Options for Diverse Sewing Needs

Industrial adopters can configure automatic threader sewing machine units with modular attachments:

- Heavy-duty motors for leather stitching (up to 8mm thickness)

- Programmable embroidery patterns (500+ built-in designs)

- IoT-enabled production tracking compatible with ERP systems

Real-World Applications in Textile Industries

A automotive upholstery manufacturer reported 38% faster seat cover production after implementing 20 TechStitch X9 units. Case studies demonstrate:

"Our defect rate dropped from 12% to 1.4% within 3 months, directly improving ROI by 22%."

Maintenance Tips for Long-Term Efficiency

Regular calibration preserves threading accuracy:

- Clean optical sensors weekly with microfiber cloth

- Replace guide bushings every 50,000 stitches

- Update firmware quarterly for performance enhancements

How Automatic Threader Sewing Machines Shape Manufacturing Futures

With 62% of garment factories planning automation upgrades by 2025, serger sewing machine automatic threader technology becomes indispensable. Emerging models integrate machine learning to predict thread breakage 15 minutes in advance, potentially saving $18,000 annually per production line. This evolution positions automated threading systems as the cornerstone of sustainable, high-yield textile manufacturing.

(sewing machine with automatic threader)

FAQS on sewing machine with automatic threader

Q: How does an automatic threader work on a sewing machine?

A: An automatic threader uses a small mechanical hook or lever to guide the thread through the needle eye effortlessly. It simplifies threading, especially for users with vision or dexterity challenges. Most models include a button or lever to activate the feature.

Q: What are the benefits of a sewing machine with an automatic needle threader?

A: It saves time and reduces frustration when threading needles manually. This feature improves accuracy and minimizes eye strain. It’s ideal for frequent sewers or those working with fine fabrics.

Q: Can automatic threaders be used on serger sewing machines?

A: Some high-end serger sewing machines with automatic threaders include this feature for multiple loopers and needles. However, threading a serger’s multiple threads may still require partial manual steps. Check the product specifications for compatibility.

Q: How do I maintain an automatic threader on my sewing machine?

A: Clean the threader regularly to remove lint or debris that could jam the mechanism. Avoid forcing the threader if it resists, as this may damage components. Refer to the user manual for model-specific care instructions.

Q: Are automatic threader sewing machines suitable for beginners?

A: Yes, they simplify the threading process, making them beginner-friendly. Many entry-level models now include this feature to ease learning curves. It also reduces setup time for quick project starts.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025