High-efficiency Sewing Machine for PP Woven Bags Production and Customization

The Importance of PP Woven Bag Sewing Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing, the efficiency and reliability of production processes remain paramount. Among various machinery that contribute to this efficiency, the PP (polypropylene) woven bag sewing machine stands out as a critical tool, particularly in industries that require durable packaging solutions. These machines are specifically designed for sewing PP woven bags, which are widely used in agricultural, industrial, and retail applications.

Understanding PP Woven Bags

PP woven bags are made from polypropylene, a versatile thermoplastic polymer that offers excellent strength, flexibility, and resistance to moisture and chemicals. These bags are typically used for packaging agricultural products such as grains, fertilizers, and animal feed, as well as industrial goods like cement and chemicals. Thanks to their durability and lightweight nature, PP woven bags have become a preferred choice over traditional paper and plastic alternatives.

The Role of Sewing Machines in Production

The manufacturing process of PP woven bags involves weaving polypropylene threads into a fabric-like structure, which is then cut and sewn into bags of various sizes and styles. A sewing machine specifically configured for PP woven materials is crucial in this process. These machines are engineered to handle the robust nature of the woven fabric, ensuring that the stitching is tight and resilient.

Key Features of PP Woven Bag Sewing Machines

2. Speed and Efficiency Modern PP woven bag sewing machines are designed for speed, allowing manufacturers to produce a higher number of bags in a shorter time frame. This aspect is vital in meeting the growing demand in various sectors.

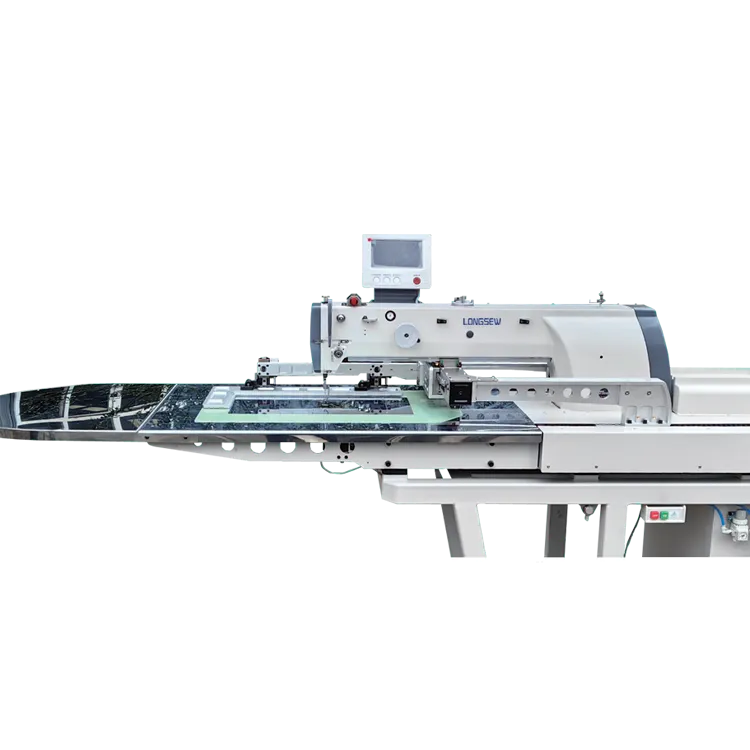

pp woven bag sewing machine

3. Versatility Many of these machines are equipped with the capability to sew different bag styles, including open mouth bags, valve bags, and gusset bags, catering to a wide range of packaging needs.

4. User-Friendly Controls Advanced sewing machines come with easy-to-use controls and automation features that streamline the operation, allowing even workers with minimal training to operate them efficiently.

5. Precision The ability to create precision stitches ensures that the bags are sealed properly, reducing the risk of leakage and ensuring product integrity during transportation and storage.

The Impact on Cost Efficiency and Sustainability

Investing in a high-quality PP woven bag sewing machine can significantly reduce production costs by minimizing waste and increasing output. Manufacturers can achieve greater consistency and quality in their products, which reduces the likelihood of returns and enhances customer satisfaction.

Furthermore, as the world continues to move towards sustainable practices, the demand for eco-friendly packaging solutions is on the rise. PP woven bags are recyclable, and their production process can be optimized to reduce energy consumption and waste. The efficiency offered by modern sewing machines contributes to a more sustainable production cycle, aligning with global efforts to minimize environmental impact.

Conclusion

The PP woven bag sewing machine is an indispensable tool in the packaging industry, facilitating the production of strong, reliable, and cost-effective solutions for various applications. As industries continue to embrace automation and efficient processes, these machines will play a pivotal role in shaping the future of packaging. Investing in advanced sewing technology not only enhances productivity but also aligns with the broader goals of sustainability and efficiency in manufacturing. Embracing this technology will undoubtedly prepare businesses to meet the challenges of a competitive market while catering to the growing demand for high-quality packaging solutions.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025