PP Woven Bag Cutting and Stitching Equipment for Efficient Production

The Innovations in PP Woven Bag Cutting and Sewing Machines

In the rapidly evolving landscape of industrial manufacturing, the production of polypropylene (PP) woven bags has seen significant advancements, particularly in the development of cutting and sewing machines designed specifically for this purpose. These machines have revolutionized the way these versatile bags are produced, enhancing efficiency, precision, and overall quality.

PP woven bags are the preferred choice in various industries due to their strength, durability, and resistance to water and chemicals. Commonly used for packaging agricultural products, fertilizers, construction materials, and consumer goods, the demand for these bags has surged in recent years. This increase in demand has prompted manufacturers to refine their production processes, leading to the emergence of specialized cutting and sewing machines.

Efficiency and Speed

The primary advantage of modern PP woven bag cutting and sewing machines is their efficiency. Traditional methods of bag production were often labor-intensive and time-consuming. However, today’s machines incorporate advanced automation technology that significantly speeds up the cutting and sewing processes. Automated cutting tools ensure that each bag is cut precisely to the required dimensions, while high-speed sewing machines can stitch them together in a matter of seconds. This enhanced productivity allows manufacturers to meet growing market demands more effectively without compromising quality.

Precision in Production

Accuracy in measurement and assembly is crucial in the production of PP woven bags. Any discrepancies in size or stitching can lead to product wastage and reduced customer satisfaction. Modern cutting and sewing machines utilize computer numerical control (CNC) technology, which guarantees high precision in cutting fabrics to the exact measurements needed. This technology also reduces material wastage, leading to cost savings for manufacturers. Moreover, with the integration of advanced sensors and software, these machines can detect inconsistencies in the fabric and adjust settings in real-time, ensuring that each bag meets stringent quality standards.

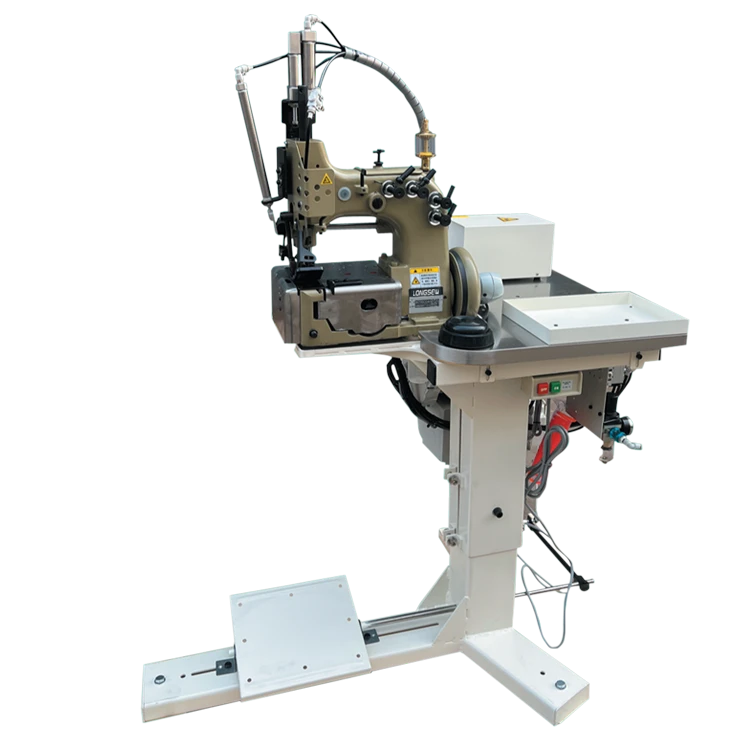

pp woven bag cutting and sewing machine

User-Friendly Interfaces

Another remarkable aspect of today’s PP woven bag cutting and sewing machines is their user-friendly interfaces. These machines are designed with operators in mind; intuitive controls and touchscreen displays simplify the operation process. Manufacturers can program different bag specifications into the machine, allowing for quick adjustments to produce various bag styles and sizes depending on market demands. This flexibility is crucial for businesses looking to maintain competitiveness in a dynamic environment.

Sustainability Considerations

With the growing emphasis on sustainability, manufacturers are increasingly focusing on eco-friendly practices. Modern cutting and sewing machines are designed to minimize waste and are often made from sustainable materials. Additionally, the efficiency of these machines translates into lower energy consumption during the production process, reducing the environmental impact. By investing in advanced machinery, companies are not only increasing their production capabilities but also contributing positively to environmental conservation.

Conclusion

The advancements in PP woven bag cutting and sewing machines have transformed the manufacturing landscape, offering solutions that enhance efficiency, precision, and sustainability. As industries continue to embrace these innovations, the future of PP woven bag production looks promising. Manufacturers who invest in modern technology will not only keep pace with market demands but also ensure that they remain competitive in an ever-evolving economic environment. The integration of automation, precision engineering, and sustainable practices positions these machines as essential assets in the future of packaging solutions.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025