Фев . 15, 2025 03:41

Back to list

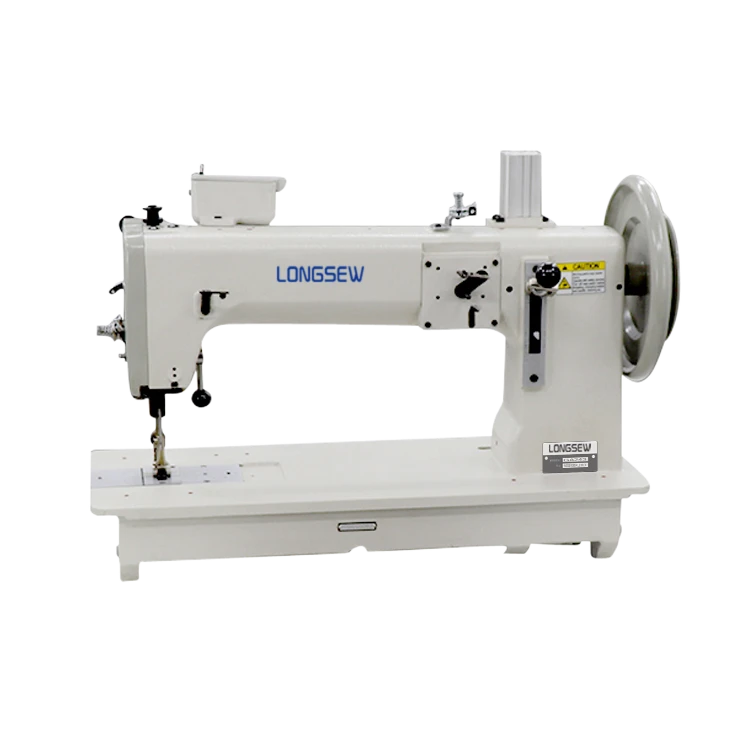

jumbo bag stitching machine

The world of packaging has witnessed a significant transformation with the advent of innovative machinery aimed at improving efficiency and quality. Among these advancements, the PP bag hand stitching machine stands out as a pivotal tool for businesses in the packaging industry.

Trustworthiness in machines is characterized by their reliability and the manufacturer's commitment to quality assurance. Top-tier PP bag hand stitching machines undergo rigorous testing to meet international standards such as ISO certification. Additionally, manufacturers provide extensive warranties and after-sales services, which are critical in maintaining operational continuity and handling unexpected breakdowns. From a commercial perspective, purchasing decisions should not merely hinge on the machine’s upfront cost but should also consider long-term factors such as energy efficiency, maintenance requirements, and availability of spare parts. Businesses are advised to seek machines that boast low energy consumption, reducing operational costs and contributing to sustainability initiatives. Regular maintenance, facilitated by easy-to-obtain spare components, ensures that machines remain in peak condition, further solidifying the machine's role in sustainable business operations. For businesses contemplating the acquisition of a PP bag hand stitching machine, understanding the market landscape is crucial. A thorough comparison between models based on stitching speed, thread compatibility, and ease of use can reveal the best-suited machine for specific needs. Testimonials and case studies from similar companies can provide valuable insights into real-world performance and reliability, fostering an informed purchase. Moreover, an investment in a PP bag hand stitching machine is also an investment in the workforce operating it. Training programs should highlight safety protocols and include regular updates on machine enhancements to bolster productivity while safeguarding employee welfare. As automation continues to influence the packaging sector, ensuring that staff are adept at machine operation becomes an investment towards a more secure and efficient organizational workflow. In conclusion, navigating the competitive and ever-evolving arena of packaging requires informed decision-making, particularly when selecting equipment like PP bag hand stitching machines. By prioritizing expertise, leveraging authoritative resources, and committing to trust-building practices through exceptional quality and service, businesses can achieve unmatched efficiency and product reliability. Ultimately, choosing the right machinery facilitates not only superior packaging solutions but also a sturdy foundation for sustained growth and industry leadership.

Trustworthiness in machines is characterized by their reliability and the manufacturer's commitment to quality assurance. Top-tier PP bag hand stitching machines undergo rigorous testing to meet international standards such as ISO certification. Additionally, manufacturers provide extensive warranties and after-sales services, which are critical in maintaining operational continuity and handling unexpected breakdowns. From a commercial perspective, purchasing decisions should not merely hinge on the machine’s upfront cost but should also consider long-term factors such as energy efficiency, maintenance requirements, and availability of spare parts. Businesses are advised to seek machines that boast low energy consumption, reducing operational costs and contributing to sustainability initiatives. Regular maintenance, facilitated by easy-to-obtain spare components, ensures that machines remain in peak condition, further solidifying the machine's role in sustainable business operations. For businesses contemplating the acquisition of a PP bag hand stitching machine, understanding the market landscape is crucial. A thorough comparison between models based on stitching speed, thread compatibility, and ease of use can reveal the best-suited machine for specific needs. Testimonials and case studies from similar companies can provide valuable insights into real-world performance and reliability, fostering an informed purchase. Moreover, an investment in a PP bag hand stitching machine is also an investment in the workforce operating it. Training programs should highlight safety protocols and include regular updates on machine enhancements to bolster productivity while safeguarding employee welfare. As automation continues to influence the packaging sector, ensuring that staff are adept at machine operation becomes an investment towards a more secure and efficient organizational workflow. In conclusion, navigating the competitive and ever-evolving arena of packaging requires informed decision-making, particularly when selecting equipment like PP bag hand stitching machines. By prioritizing expertise, leveraging authoritative resources, and committing to trust-building practices through exceptional quality and service, businesses can achieve unmatched efficiency and product reliability. Ultimately, choosing the right machinery facilitates not only superior packaging solutions but also a sturdy foundation for sustained growth and industry leadership.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025