Янв . 09, 2025 13:47

Back to list

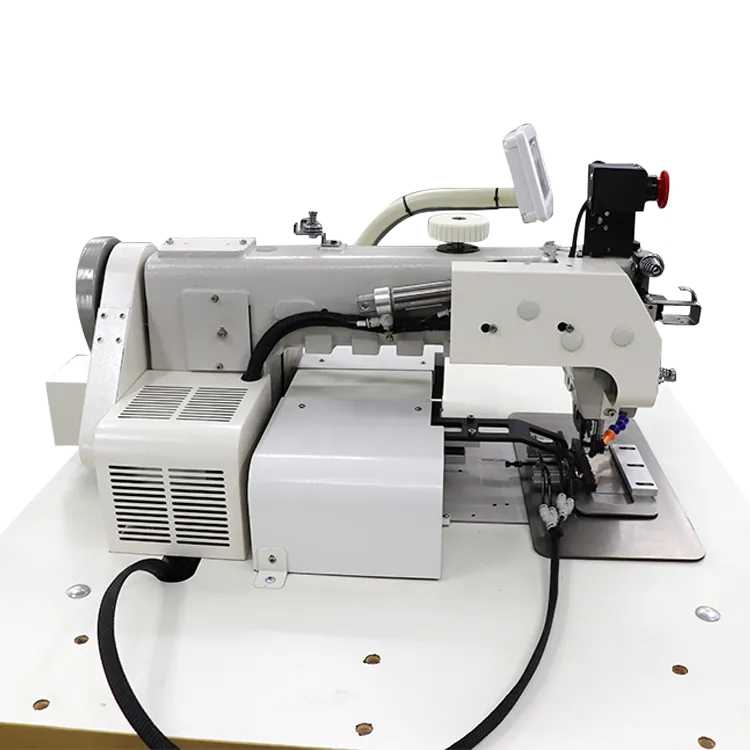

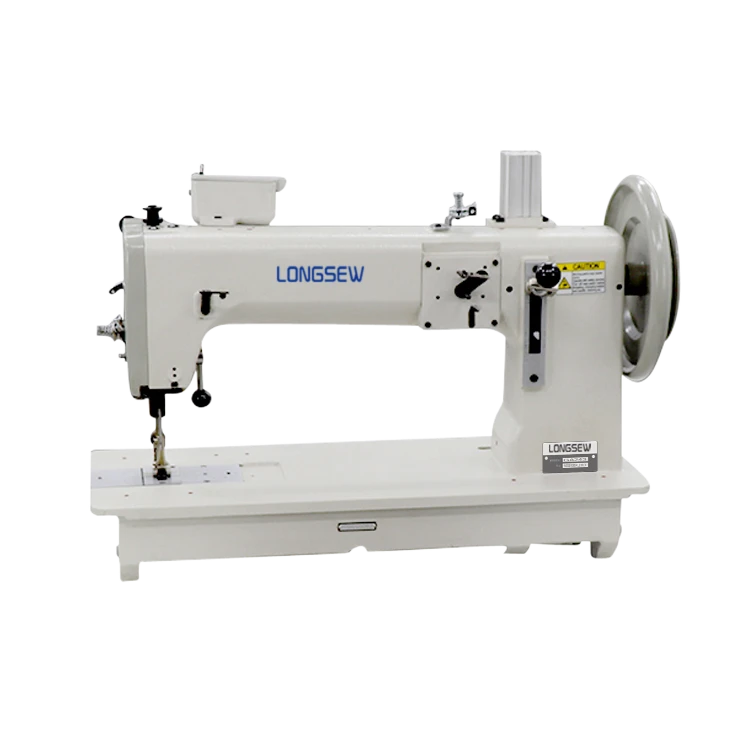

PP Woven Bag / Big Bag Single Needle 2 Threads Chainstitch Sewing Machine Head DN-2HS / DN-2LHS

For businesses involved in bulk materials handling, the choice of equipment can define productivity, efficiency, and safety standards. One piece of equipment that fundamentally changes operational dynamics is the jumbo bag sewing machine. This powerful tool not only enhances efficiency but also guarantees the quality and durability required for storing and transporting bulk products. As an experienced industry professional, I understand the myriad of benefits that an advanced jumbo bag sewing machine offers.

Authoritativeness in the industry often comes from leveraging technology to solve material handling challenges. The most advanced jumbo bag sewing machines integrate intelligent systems that provide real-time diagnostics and maintenance alerts, ensuring machines run smoothly with minimal downtime. As someone with authority in equipment optimization, I have seen how these features enhance operational efficiency and significantly reduce maintenance costs, thereby offering a substantial return on investment. Business owners should prioritize machines from reputable manufacturers who are recognized for their innovation and commitment to quality. Trustworthiness in business relies heavily on equipment that guarantees consistent output. Investing in a high-quality jumbo bag sewing machine that is both durable and backed by comprehensive after-sales support reflects a dedication to operational integrity. Trust is built by choosing manufacturers who offer extensive warranties and responsive customer service, ensuring any technical issues are promptly addressed, thereby maintaining production flow with minimal interruptions. In conclusion, for any industry dealing with large-scale materials handling, leveraging the capabilities of a jumbo bag sewing machine is foundational to advancing operational standards. Its automation capabilities, adaptable settings, and technological integrations not only streamline production but also uphold the highest quality standards. As a professional with a keen eye on maximizing productivity, integrating this equipment into your operations not only revolutionizes efficiency but also positions your business at the forefront of the industry, driving growth and competitiveness.

Authoritativeness in the industry often comes from leveraging technology to solve material handling challenges. The most advanced jumbo bag sewing machines integrate intelligent systems that provide real-time diagnostics and maintenance alerts, ensuring machines run smoothly with minimal downtime. As someone with authority in equipment optimization, I have seen how these features enhance operational efficiency and significantly reduce maintenance costs, thereby offering a substantial return on investment. Business owners should prioritize machines from reputable manufacturers who are recognized for their innovation and commitment to quality. Trustworthiness in business relies heavily on equipment that guarantees consistent output. Investing in a high-quality jumbo bag sewing machine that is both durable and backed by comprehensive after-sales support reflects a dedication to operational integrity. Trust is built by choosing manufacturers who offer extensive warranties and responsive customer service, ensuring any technical issues are promptly addressed, thereby maintaining production flow with minimal interruptions. In conclusion, for any industry dealing with large-scale materials handling, leveraging the capabilities of a jumbo bag sewing machine is foundational to advancing operational standards. Its automation capabilities, adaptable settings, and technological integrations not only streamline production but also uphold the highest quality standards. As a professional with a keen eye on maximizing productivity, integrating this equipment into your operations not only revolutionizes efficiency but also positions your business at the forefront of the industry, driving growth and competitiveness.

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025