Янв . 09, 2025 12:24

Back to list

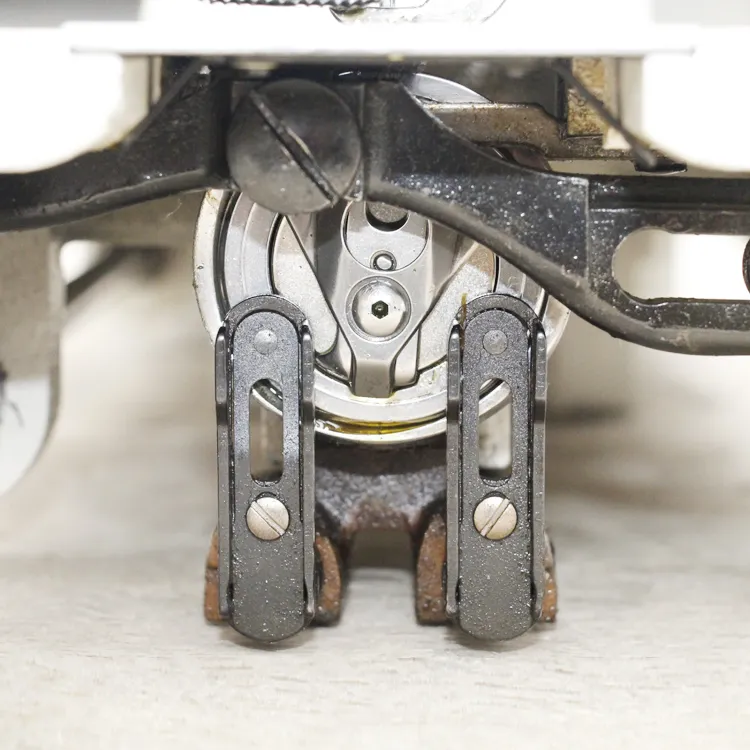

jumbo bag sewing machine

Sewing machines form the backbone of textile industries, and when it comes to crafting strong, capacious, and durable packaging solutions, jumbo bag sewing machines are unparalleled. These robust machines are essential for creating bags that are capable of carrying massive loads, often reaching several hundred kilograms, and are indispensable in sectors such as shipping, agriculture, and construction.

From an authoritative standpoint, jumbo bag sewing machines must comply with international safety standards, such as the ISO 11111 standards for textile machinery safety measures. Acquiring machines from established manufacturers with a reputation for producing durable and compliant equipment assures buyers of quality and safety. These companies often offer certifications and extensive warranties, underscoring their commitment to reliability and client satisfaction. Trust, in the context of industrial machinery, is built through demonstrable durability and after-sales support. Opting for brands with dedicated customer service teams and accessible technical support personnel can significantly enhance user experience. Many suppliers now offer virtual tutorials and machine maintenance guides, further instilling confidence and trust among operators and business owners, ensuring their investment reaps long-term benefits. In conclusion, investing in a jumbo bag sewing machine goes beyond transactional purchase—it's about forging partnerships with manufacturers of repute, understanding the operational nuances, and ensuring compliance with safety standards. Only then can businesses truly harness the potential of these indispensable industrial sewing giants, optimizing their production capabilities whilst ensuring safety and precision in every stitch.

From an authoritative standpoint, jumbo bag sewing machines must comply with international safety standards, such as the ISO 11111 standards for textile machinery safety measures. Acquiring machines from established manufacturers with a reputation for producing durable and compliant equipment assures buyers of quality and safety. These companies often offer certifications and extensive warranties, underscoring their commitment to reliability and client satisfaction. Trust, in the context of industrial machinery, is built through demonstrable durability and after-sales support. Opting for brands with dedicated customer service teams and accessible technical support personnel can significantly enhance user experience. Many suppliers now offer virtual tutorials and machine maintenance guides, further instilling confidence and trust among operators and business owners, ensuring their investment reaps long-term benefits. In conclusion, investing in a jumbo bag sewing machine goes beyond transactional purchase—it's about forging partnerships with manufacturers of repute, understanding the operational nuances, and ensuring compliance with safety standards. Only then can businesses truly harness the potential of these indispensable industrial sewing giants, optimizing their production capabilities whilst ensuring safety and precision in every stitch.

Previous:

Next:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025