Фев . 12, 2025 15:56

Back to list

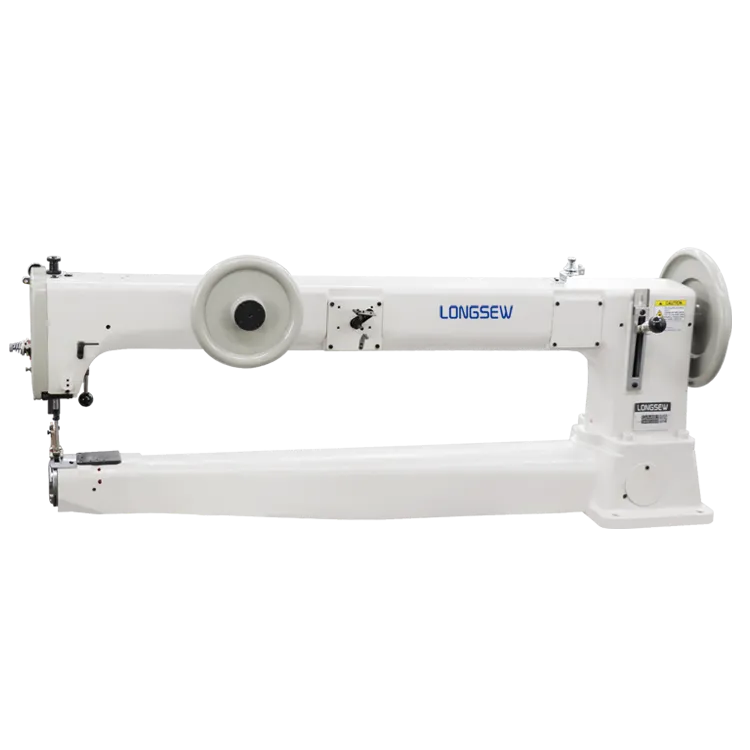

Long Arm Heavy Duty Cylinder Bed Horizontal Direction Sewing Machine For Like Boot Long Barrel Products GA411N

When it comes to industrial machines for sewing leather, discerning craftsmen and production line managers alike understand the need for equipment that balances precision, durability, and power. Leather, a material known for its robustness, demands machinery that is up to the task of handling its often-unyielding nature. This exploration into industrial leather sewing machines delves into what makes them unique and the standards by which their performance is gauged.

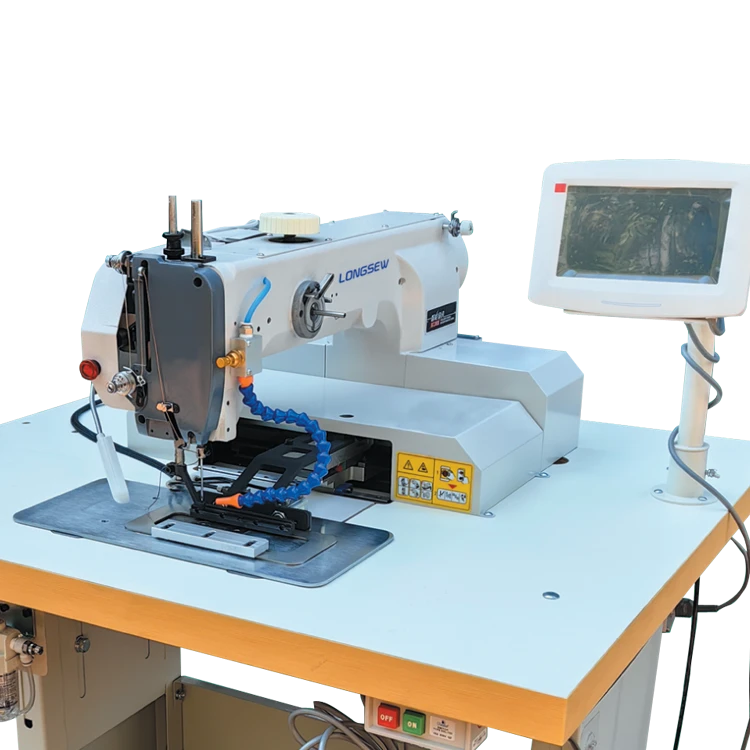

Moreover, the build quality of industrial leather sewing machines cannot be understated. The frame and inner components must withstand considerable wear and tear. Typically constructed from high-grade metal, these machines are designed to endure high-volume production demands over years without faltering. This robustness translates into a longer lifespan, offering a greater return on investment. Now, considering expertise in the field, professional recommendations often steer towards brands with a proven track record in the industrial market. Brands that have specialized in manufacturing heavy-duty machines for decades bring insights and innovations that newer entrants might lack. Choosing such trusted brands not only ensures technical support and availability of spare parts but also gives peace of mind knowing that machine reliability is backed by a solid reputation. Trustworthiness and authoritativeness come into play when evaluating these machines. A reliable machine demonstrates consistency in output, essential for maintaining client trust and satisfaction. It also minimizes the risk of defects and rework, which can be costly and damaging to reputation. Furthermore, authoritative machines offer technological advancements such as digital integration for precise monitoring and control, helping businesses stay at the forefront of the industry. In summary, the choice of an industrial machine for sewing leather is pivotal in determining production quality and efficiency. It is an investment that requires careful consideration of the machine's ability to handle demanding materials, its motor's power, needle system, and overall construction. By prioritizing these aspects, businesses can ensure they acquire a machine that not only meets but exceeds their leather production needs, sustaining their place in the competitive market.

Moreover, the build quality of industrial leather sewing machines cannot be understated. The frame and inner components must withstand considerable wear and tear. Typically constructed from high-grade metal, these machines are designed to endure high-volume production demands over years without faltering. This robustness translates into a longer lifespan, offering a greater return on investment. Now, considering expertise in the field, professional recommendations often steer towards brands with a proven track record in the industrial market. Brands that have specialized in manufacturing heavy-duty machines for decades bring insights and innovations that newer entrants might lack. Choosing such trusted brands not only ensures technical support and availability of spare parts but also gives peace of mind knowing that machine reliability is backed by a solid reputation. Trustworthiness and authoritativeness come into play when evaluating these machines. A reliable machine demonstrates consistency in output, essential for maintaining client trust and satisfaction. It also minimizes the risk of defects and rework, which can be costly and damaging to reputation. Furthermore, authoritative machines offer technological advancements such as digital integration for precise monitoring and control, helping businesses stay at the forefront of the industry. In summary, the choice of an industrial machine for sewing leather is pivotal in determining production quality and efficiency. It is an investment that requires careful consideration of the machine's ability to handle demanding materials, its motor's power, needle system, and overall construction. By prioritizing these aspects, businesses can ensure they acquire a machine that not only meets but exceeds their leather production needs, sustaining their place in the competitive market.

Latest news

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025