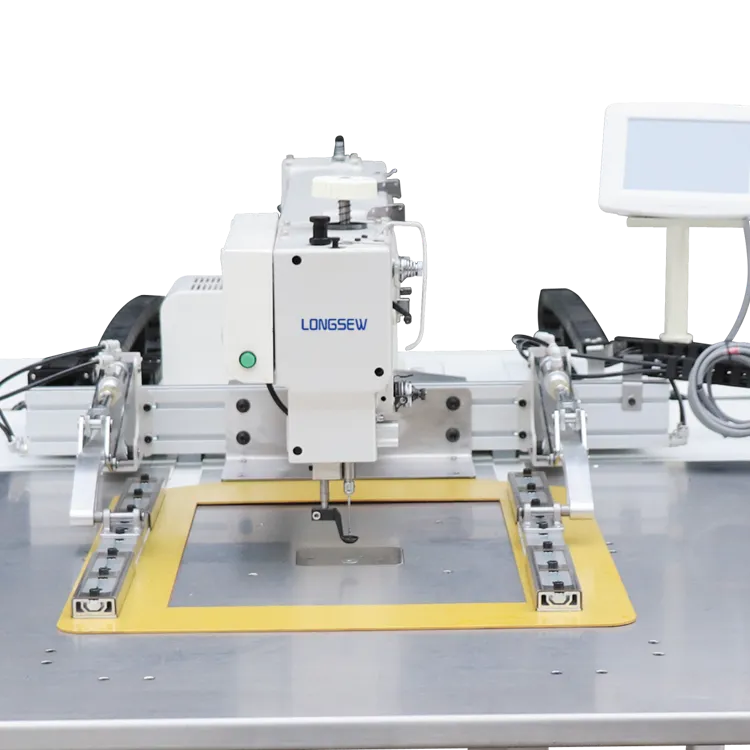

Industrial Sewing Machine with Lockstitch Technology for Efficient Fabric Production

The Versatility and Functionality of Industrial Lockstitch Machines

In the world of textile manufacturing, the industrial lockstitch machine stands out as a crucial tool that has revolutionized the way garments are produced. This sewing machine is known for its exceptional ability to create strong, durable stitches, making it an indispensable asset in factories and workshops around the globe.

Understanding the Lockstitch Mechanism

At the heart of the industrial lockstitch machine is its unique stitching mechanism. It utilizes two threads—one from the spool and one from the bobbin—to create a secure stitch. The needle pierces the fabric, drawing the upper thread down, while the bobbin thread comes up to form a lock at the bottom. This method not only ensures a tight stitch but also provides a clean finish on both sides of the fabric. The lockstitch is particularly favored for its ability to handle heavy materials, making it ideal for denim, canvas, and other robust textiles.

Efficiency in Production

One of the primary advantages of industrial lockstitch machines is their efficiency in production. These machines are designed for high-speed operation, capable of sewing at rates of 5,000 stitches per minute or more. This makes them perfect for mass production lines where time is of the essence. Operators can complete tasks quickly without compromising on stitch quality, thereby enhancing productivity and meeting the demands of fast-paced fashion markets.

Adaptability to Various Applications

industrial lockstitch machine

Industrial lockstitch machines are incredibly versatile, able to accommodate different sewing needs and techniques. They are commonly used for a range of applications, from manufacturing clothing to producing upholstery, bags, and industrial textiles. With various attachments and modifications available, these machines can sew straight lines, curves, and even intricate patterns, depending on the requirements of the project at hand.

Durability and Longevity

One of the defining features of industrial lockstitch machines is their durability. Built to withstand the demands of high-volume sewing, these machines are made from high-quality materials that ensure longevity. Regular maintenance and proper handling can provide years of reliable service, making them a cost-effective option for businesses. Investing in a robust lockstitch machine often outweighs the need for frequent repairs or replacements, thus enhancing the overall efficiency of manufacturing processes.

Technological Advancements

In recent years, advancements in technology have further improved the functionality of industrial lockstitch machines. Modern versions now come equipped with computerized controls that allow for precise stitch regulation and pattern programming. This technological shift has enabled manufacturers to enhance their craftsmanship and achieve results that were previously unfeasible. Automatic threading and tension adjustment features also reduce the time spent on setup, allowing for quicker transitions between projects.

Conclusion

The industrial lockstitch machine remains a cornerstone of the textile industry. Its ability to deliver strong, reliable stitches, paired with its efficiency and versatility, makes it the go-to choice for many manufacturers. As technology continues to evolve, these machines are likely to integrate even more advanced features, ensuring they remain relevant in an ever-changing market. For businesses looking to optimize their sewing operations, investing in an industrial lockstitch machine is undeniably a step towards greater productivity and quality in their products.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025