Фев . 15, 2025 00:10

Back to list

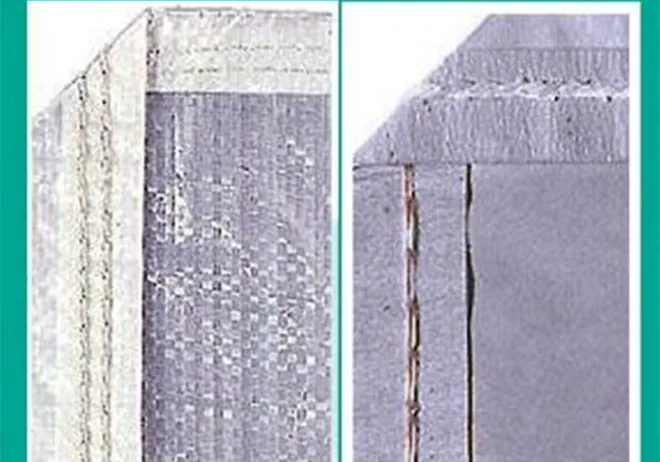

gunny bag stitching machine

A gunny bag stitching machine stands as a vital component in the industrial packaging and textile sectors, offering both efficiency and cost-effectiveness. These machines, engineered to automate the tedious task of stitching burlap or jute sacks, ensure a robust sealing process vital for industries relying on bulk packaging, such as agriculture and construction. Through combining mechanical precision with innovative technology, these machines have revolutionized how businesses manage large-scale packaging operations.

In terms of authoritativeness, manufacturers and brands specializing in gunny bag stitching machines play a significant role. Brands reputed for durable materials and superior after-sales support should be prioritized, as their credibility is often a testament to the machine's quality. This, in turn, translates to less downtime, minimized maintenance costs, and extended machine lifespan. Engaging with industry reviews, case studies, and pilot programs by these manufacturers can shed light on a machine's long-term efficiency and reliability. Trustworthiness comes into play with the legal and warranty aspects of the purchase. Due diligence with respect to compliance with industry standards and safety protocols should never be underestimated. The warranty terms, including service support and part replacement guarantees, should be thoroughly reviewed. Businesses must also ensure that machines are certified for safety and compliance by recognized industry bodies, adding an additional layer of trust and reducing the risk of operational setbacks. Finally, sustainability is becoming an increasingly relevant component of gunny bag stitching machine operations. The environmental impact of packaging has drawn attention to machines that conserve energy and minimize waste. By choosing environmentally friendly machines that offer energy-saving modes and efficient operational cycles, businesses not only reduce their carbon footprint but also appeal to an eco-conscious market. In essence, investing in a gunny bag stitching machine requires more than just financial outlay; it involves a comprehensive understanding of both the machine's technical capabilities and the strategic needs of the business. A sound investment in a high-quality, reliable stitching machine can yield sustained operational efficiencies and establish the business's standing in a competitive industry landscape. With ongoing advancements in technology, those in the sector must stay informed of emerging trends and innovations for continued growth and adaptability.

In terms of authoritativeness, manufacturers and brands specializing in gunny bag stitching machines play a significant role. Brands reputed for durable materials and superior after-sales support should be prioritized, as their credibility is often a testament to the machine's quality. This, in turn, translates to less downtime, minimized maintenance costs, and extended machine lifespan. Engaging with industry reviews, case studies, and pilot programs by these manufacturers can shed light on a machine's long-term efficiency and reliability. Trustworthiness comes into play with the legal and warranty aspects of the purchase. Due diligence with respect to compliance with industry standards and safety protocols should never be underestimated. The warranty terms, including service support and part replacement guarantees, should be thoroughly reviewed. Businesses must also ensure that machines are certified for safety and compliance by recognized industry bodies, adding an additional layer of trust and reducing the risk of operational setbacks. Finally, sustainability is becoming an increasingly relevant component of gunny bag stitching machine operations. The environmental impact of packaging has drawn attention to machines that conserve energy and minimize waste. By choosing environmentally friendly machines that offer energy-saving modes and efficient operational cycles, businesses not only reduce their carbon footprint but also appeal to an eco-conscious market. In essence, investing in a gunny bag stitching machine requires more than just financial outlay; it involves a comprehensive understanding of both the machine's technical capabilities and the strategic needs of the business. A sound investment in a high-quality, reliable stitching machine can yield sustained operational efficiencies and establish the business's standing in a competitive industry landscape. With ongoing advancements in technology, those in the sector must stay informed of emerging trends and innovations for continued growth and adaptability.

Previous:

Next:

Latest news

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025