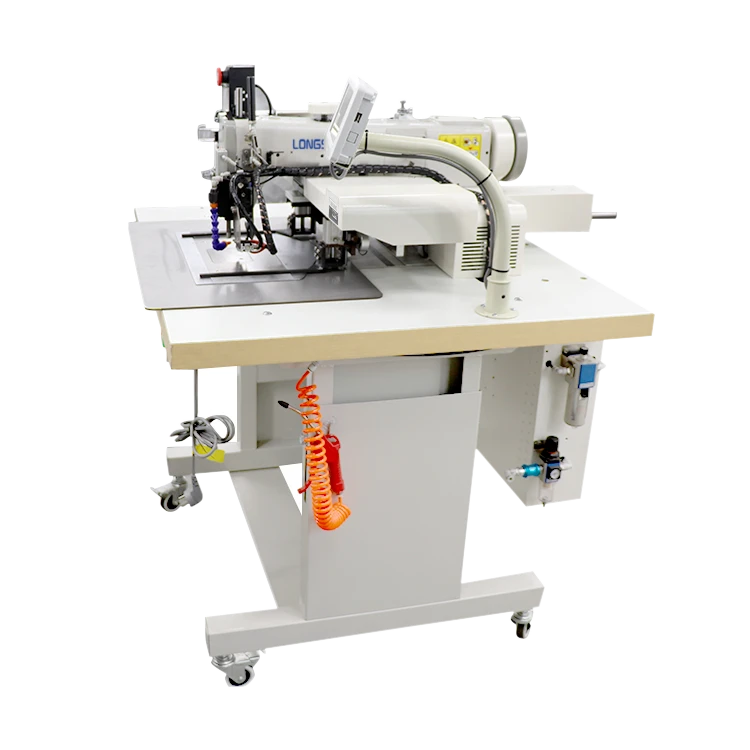

fibc bag baffle sewing machine

The Importance of Baffle Sewing Machines in FIBC Production

In the ever-evolving landscape of industrial packaging, Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags, play a critical role in transporting and storing dry bulk materials. With diverse applications in various industries, FIBCs must not only be strong and durable but also designed for ease of handling and efficiency. One of the unsung heroes in the production of these vital bags is the baffle sewing machine, a specialized piece of equipment designed to enhance the structural integrity and usability of FIBCs.

Understanding FIBCs and Their Design

FIBCs are large bags made from woven fabric, typically polypropylene, used to transport bulk materials like chemicals, food products, and construction materials. The design of these bags can significantly impact their performance, particularly when it comes to shape retention and stability. Baffles are internal partitions sewn into the bag, which help maintain its shape when filled. This prevents bulging and allows the bag to stand upright during filling and storage, improving the efficiency of loading and unloading processes.

The Role of Baffle Sewing Machines

The sewing of baffles into FIBCs is a critical step in the manufacturing process. Baffle sewing machines are specially designed to create precise stitches that secure these internal supports within the bag. The efficiency and quality of these machines directly affect the performance of the final product.

1. Precision and Consistency Baffle sewing machines are engineered for accuracy. They ensure that the baffles are sewn in precise locations within the bag, providing optimal support and maintaining the intended shape. This precision is particularly vital in high-production environments where hundreds or thousands of bags are produced daily.

2. Durability The materials used in FIBCs, often robust and heavy-duty, require strong stitching to ensure longevity. Baffle sewing machines are equipped to handle thick fabrics and multiple layers, producing durable seams that withstand the pressures of filling and transportation.

fibc bag baffle sewing machine

3. Efficiency Automated baffle sewing machines significantly increase production speed compared to manual methods. They can sew multiple baffles in a single run, reducing the time required for bag assembly and allowing manufacturers to meet high demand efficiently.

4. Versatility Modern baffle sewing machines are versatile and programmable, capable of handling a variety of bag sizes and specifications. This flexibility is essential as businesses may require different designs based on the materials being transported or specific customer requirements.

Technology and Innovation in Baffle Sewing Machines

As with many industrial machines, technological advancements have led to more sophisticated baffle sewing machines. Features such as computerized controls allow for quick adjustments and easy data management, helping operators streamline their processes. Furthermore, advancements in sewing technology, such as enhanced needle designs and automated tension adjustments, contribute to improved sewing quality and reduced downtime.

One example of innovation is the integration of laser cutting technology, which can accurately prepare fabric pieces before sewing. This reduces waste and ensures that each component fits perfectly, leading to an overall enhancement in the quality of the FIBC.

The Future of FIBC Production

As industries increasingly turn to bulk bags for their efficiency and effectiveness, the demand for high-quality FIBCs will continue to rise. Consequently, the importance of reliable baffle sewing machines cannot be overstated. Manufacturers that invest in advanced baffle sewing technologies will not only improve their production capabilities but also enhance the quality and functionality of their products.

In conclusion, baffle sewing machines are indispensable to the FIBC manufacturing process. They enable the creation of bags that are not only robust and reliable but also user-friendly and efficient. As technology continues to progress, these machines will play a pivotal role in shaping the future of industrial packaging, ensuring that FIBCs meet the demanding needs of various sectors in a competitive marketplace. The evolution of baffle sewing machines reflects the ongoing commitment to quality, efficiency, and innovation in industrial manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025