Advanced Cylinder Sewing Machine for Enhanced Fabric Handling and Precision Stitching Solutions

The Revolution of Cylinder Sewing Machines in Textile Manufacturing

The textile industry has undergone numerous transformations since its inception, with evolving machinery that enhances efficiency and precision. Among these ingenious inventions stands the cylinder sewing machine, a remarkable tool that has revolutionized the way fabric is stitched, particularly in the realms of garment construction and specialized textile manufacturing.

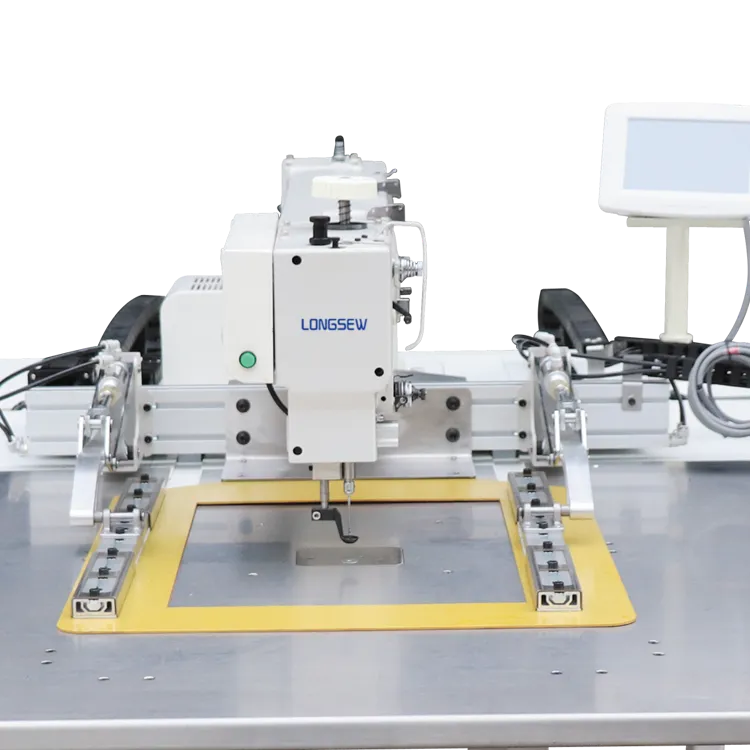

At its core, the cylinder sewing machine features a unique cylindrical arm that allows for enhanced maneuverability. This design is crucial for sewing tubular or circular pieces of fabric, such as t-shirt sleeves, cuffs, and hems. Traditional flatbed sewing machines often face limitations when it comes to handling such shapes, making the cylinder sewing machine an indispensable asset in contemporary garment production.

One of the primary advantages of the cylinder sewing machine is its ability to produce high-quality seams consistently. The machine's design ensures that the fabric remains taut while being sewn, reducing the risk of puckering or distortion. This is particularly important when working with stretchy materials, where maintaining the integrity of the fabric during assembly is essential. The result is garments that not only look professional but also fit well, enhancing customer satisfaction.

Moreover, cylinder sewing machines offer remarkable versatility. They can be equipped with various attachments and feet, enabling them to execute a wide range of stitching techniques. From overlocking to decorative stitching, the adaptability of these machines makes them suited for diverse applications within the textile industry. Manufacturers can switch effortlessly between tasks, streamlining the production process and increasing productivity.

cylinder sewing machine

The introduction of computerized technology into cylinder sewing machines has further expanded their capabilities. Modern machines often come equipped with programmable features that allow for intricate designs and patterns to be easily executed. This technology not only reduces the time taken to switch between different sewing styles but also minimizes human error, leading to a more efficient production workflow. Automation has become a key player in the textile industry, and the cylinder sewing machine is at the forefront of this innovation.

In addition to efficiency and versatility, cylinder sewing machines contribute to sustainability efforts within the textile industry. By providing more accurate and faster stitching, manufacturers can reduce fabric waste, which is a significant concern in garment production. Furthermore, the efficiency of these machines can lead to lower energy consumption, making a positive impact on the environment. As consumers become increasingly aware of sustainability issues, the adoption of such machinery can help brands align with these values.

However, incorporating cylinder sewing machines into a production line requires investment and training. While the benefits are substantial, companies must carefully consider the upfront costs and the learning curve associated with operating advanced machines. Ensuring that operators are well-trained is crucial for maximizing the potential of these sewing machines. As technology continues to evolve, ongoing education and skill development will be necessary to keep up with industry advancements.

In conclusion, cylinder sewing machines represent a significant advancement in textile manufacturing, allowing for more efficient, versatile, and high-quality production. Their unique design addresses the challenges posed by working with tubular fabric, making them an essential tool in modern garment construction. As the industry moves towards greater automation and sustainability, the role of cylinder sewing machines will only become more integral. Manufacturers who invest in these machines not only enhance their productivity but also position themselves favorably in an increasingly competitive market. As we look to the future, it is clear that the cylinder sewing machine will continue to be a driving force behind innovation in the textile industry.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025