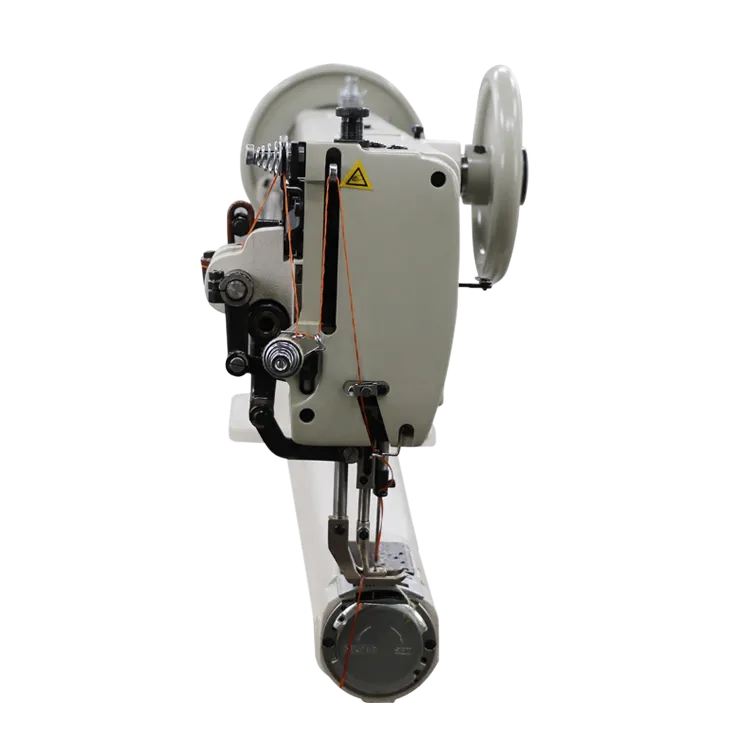

automatic woven sack cutting and stitching machine

The Advancement of Automatic Woven Sack Cutting and Stitching Machines

In the modern industrial landscape, efficiency and accuracy are paramount in production processes, especially in sectors such as packaging. One of the significant innovations facilitating this efficiency is the automatic woven sack cutting and stitching machine. This sophisticated equipment revolutionizes how woven sacks—commonly used for agricultural products, chemicals, construction materials, and more—are produced, ensuring that the operation is not only faster but also more precise.

Understanding Woven Sacks

Woven sacks are made from polypropylene or other synthetic materials, which provide strength and durability. These sacks are used for a variety of applications, including the storage and transport of grains, fertilizers, and industrial products. Traditionally, the manufacturing process of these sacks involved manual cutting and stitching, which not only consumed valuable time but also introduced a higher likelihood of human error.

The Functionality of Automatic Machines

Automatic woven sack cutting and stitching machines dramatically enhance this process. They integrate advanced technology to perform multiple tasks, including cutting fabric into the desired size, stitching the sacks securely, and sometimes even printing labels or logos. These machines often feature programmable settings that enable manufacturers to customize the size and design of the sacks according to their specific requirements. This level of automation not only improves production speed but also minimizes labor costs significantly.

One of the most notable aspects of these machines is their precision. Automatic systems are designed to maintain exact measurements and stitching quality, which means that manufacturers can produce uniform sacks that meet industry standards. The consistency provided by these machines results in fewer defects and a lower rate of returns due to poor quality.

Enhanced Productivity and Cost-Efficiency

automatic woven sack cutting and stitching machine

The introduction of automatic woven sack cutting and stitching machines has led to considerable improvements in productivity. Companies can now produce thousands of sacks in a fraction of the time it would take using manual methods. For example, while a team of workers might manage to produce a few hundred sacks in an hour, an automatic machine can easily produce several thousand. This exponential increase in output allows businesses to meet higher demands without the need to expand their workforce significantly.

Furthermore, the reduction in labor costs and waste also contributes to increased profitability. Fewer manual interventions mean lower chances of mistakes and miscalculations, which can lead to wasted materials and higher costs. Moreover, automatic machines often operate with a high degree of reliability, which decreases downtime caused by equipment failure or maintenance issues.

Technological Innovations

Recent advancements in technology have further enhanced the capabilities of woven sack cutting and stitching machines. Many models now incorporate features such as digital controls, touchscreen interfaces, and remote monitoring capabilities. This allows operators to easily adjust settings and monitor production processes in real-time. Additionally, with the rise of Industry 4.0, some machines can connect to networks for data analysis, enabling predictive maintenance and improved operational efficiency.

Environmental Considerations

As industries worldwide become more conscious of their environmental impact, the introduction of more efficient cutting and stitching machines also plays a role in sustainability. By optimizing material use and reducing waste, these machines contribute to greener production practices. Moreover, some of the latest models are designed to work with eco-friendly materials, aligning with global efforts to reduce plastic usage.

Conclusion

In conclusion, the automatic woven sack cutting and stitching machine represents a significant leap forward in the packaging industry. Its ability to enhance productivity, reduce costs, and ensure consistent quality makes it an invaluable tool for manufacturers. As technology continues to evolve, these machines will undoubtedly become even more sophisticated, further revolutionizing the production processes of woven sacks and reinforcing their critical role in various sectors worldwide. Embracing this automation is not just about keeping up with the competition; it is about setting new standards for efficiency and quality in manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025