Cost Analysis of Automatic Industrial Sewing Machines and Their Features

The Price of Automatic Industrial Sewing Machines A Comprehensive Overview

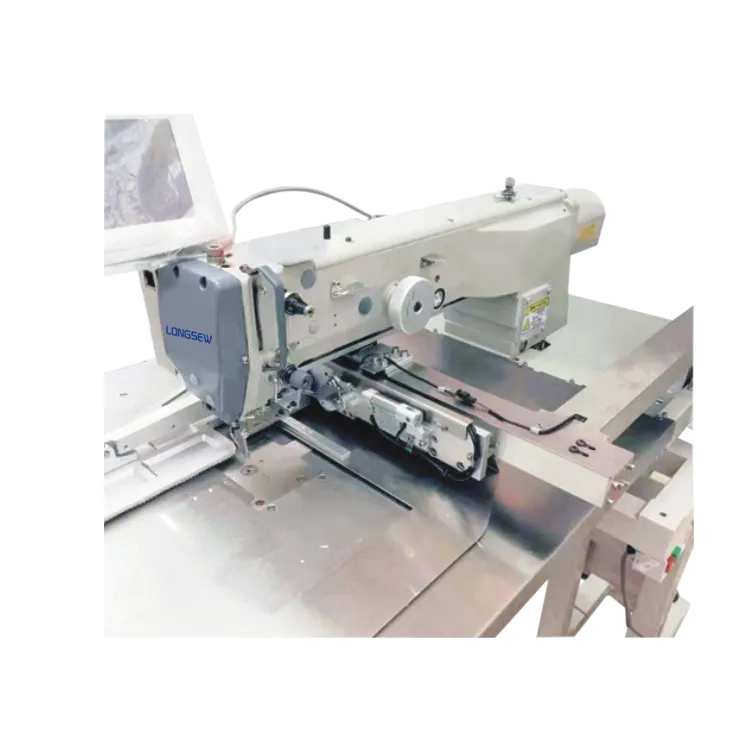

In the fast-paced world of manufacturing and garment production, the choice of equipment can significantly impact productivity, efficiency, and cost-effectiveness. One of the most essential tools in this sector is the automatic industrial sewing machine. These machines are designed to handle large-scale sewing tasks with precision and speed, making them indispensable for factories and production facilities. However, one of the most common concerns among business owners and operators is the price of these machines.

The price of an automatic industrial sewing machine can vary widely depending on several factors, including the brand, features, capabilities, and intended use. On the lower end of the spectrum, basic automatic sewing machines suitable for smaller operations might start at around $1,000. These machines typically offer essential functions such as automatic threading and basic stitch patterns.

As we move up the price scale, machines designed for more extensive operations or specialized tasks can range from $5,000 to $20,000 or more. This category includes high-speed machines capable of handling heavy fabrics or specialized sewing tasks like embroidery, quilting, or automatic pattern sewing. Such machines often feature advanced technology, such as computerized controls, automatic tension adjustment, and the ability to store multiple sewing patterns.

automatic industrial sewing machine price

In addition to the initial purchase price, it's essential to consider the total cost of ownership. This includes maintenance, operational costs, and the potential need for training staff to operate complex machinery. Regular maintenance is crucial for ensuring the longevity and reliability of an automatic industrial sewing machine. Owners should budget for routine service, which can run from a few hundred to several thousand dollars annually, depending on usage.

Furthermore, businesses must also factor in the return on investment (ROI) when considering the price of an automatic industrial sewing machine. While the upfront costs can be substantial, the efficiency gains, labor savings, and productivity improvements can lead to significant long-term savings. For instance, a machine that costs $15,000 may be able to complete tasks in half the time of a manual machine, drastically reducing labor costs over time and increasing overall output.

Another crucial influence on the price of automatic industrial sewing machines is technological advancements. With the rapid progression in automation and technology, manufacturers are continually developing smarter machines equipped with features like IoT connectivity, which allows for real-time monitoring and maintenance alerts. While these high-tech models might initially command higher prices, they often lead to lower operational costs and can be invaluable in a competitive market.

In conclusion, the price of an automatic industrial sewing machine can range dramatically based on a multitude of factors. While initial acquisition costs can be high, the potential for improved efficiency, reduced labor costs, and higher production quality presents a compelling case for investment. From smaller businesses to large-scale factories, understanding the pricing landscape and evaluating the total cost of ownership can aid in making informed purchasing decisions that ultimately contribute to a company’s bottom line. As the industry continues to evolve, staying abreast of technological advancements will also play a vital role in ensuring that manufacturers select the best sewing solutions for their specific needs, balancing both functionality and affordability.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025