50 kg jute bag making machine

The Innovations in 50% 20 kg Jute Bag Making Machines

In recent years, the demand for eco-friendly packaging solutions has surged, propelling the jute bag industry to new heights. Among the various innovations, the 50% 20 kg jute bag making machine stands out as a significant advancement in manufacturing technology. These machines not only streamline the production process but also contribute to sustainability and efficiency.

Understanding the Jute Industry

Jute, often referred to as the golden fiber, is a natural, biodegradable, and renewable resource. It is primarily grown in the tropical regions of Asia, where favorable climatic conditions allow for its abundant cultivation. The environmental benefits of using jute over synthetic materials such as plastic are substantial; jute bags decompose within a few months and do not contribute to pollution. As the world grapples with increasing plastic waste, many businesses and consumers are shifting towards jute products.

The Role of the 50% 20 kg Jute Bag Making Machine

The introduction of the 50% 20 kg jute bag making machine marks a pivotal moment in the jute industry. These machines are designed to create sturdy, eco-friendly bags that can hold up to 20 kilograms of weight, making them ideal for various applications, including agriculture, grocery, and retail.

One of the key features of these machines is their ability to produce bags with 50% reduced energy consumption compared to traditional methods. This innovation not only reduces operational costs for manufacturers but also aligns with global sustainability goals by minimizing the carbon footprint associated with production.

Efficiency and Automation

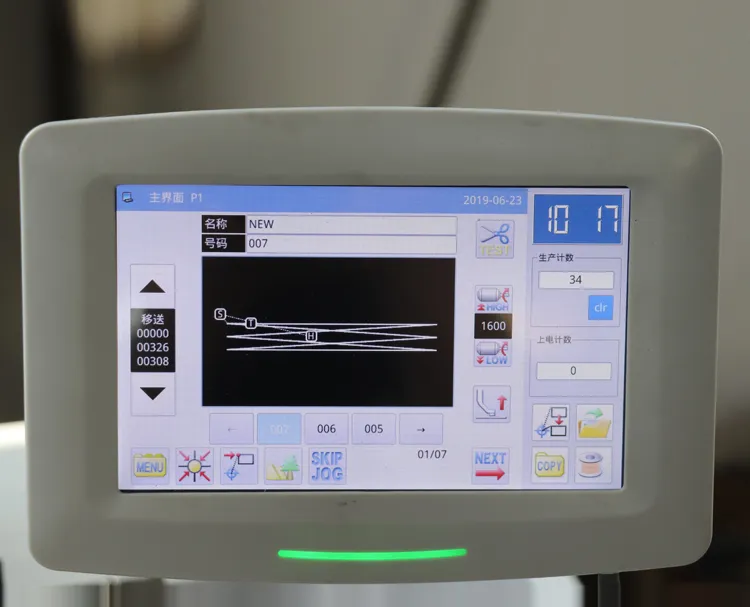

Modern jute bag making machines are equipped with advanced technology that enhances productivity. Automation plays a crucial role, as these machines can operate with minimal human intervention. This functionality not only accelerates the production process but also ensures consistent quality in the bags produced. Manufacturers can expect to achieve high output rates, meeting the ever-increasing demand for jute bags in various sectors.

Additionally, these machines include features such as automatic cutting, stitching, and printing facilities. This comprehensive approach to production allows for quick turnaround times and the capacity to fulfill large orders without compromising quality.

50 kg jute bag making machine

Economic Benefits

Investing in a 50% 20 kg jute bag making machine brings numerous economic benefits to manufacturers. Reduced energy consumption lowers the overall production cost, allowing businesses to offer competitive pricing for their products. Furthermore, as the global emphasis on sustainability grows, companies that adapt to using eco-friendly materials like jute are likely to attract a broader customer base, including environmentally conscious consumers.

Challenges in the Market

Despite the numerous advantages presented by jute bag making machines, there are challenges that manufacturers must navigate. For one, the initial investment for these advanced machines can be significant. However, the long-term savings and increased efficiency often justify the upfront cost.

Additionally, the availability of raw jute fibers can be affected by climatic conditions, as jute is highly dependent on monsoon weather patterns. Fluctuating prices and supply constraints can pose challenges for manufacturers, emphasizing the need for strategic sourcing and inventory management.

The Future of Jute Bags

Looking ahead, the future of the jute bag industry appears promising. With increasing awareness regarding environmental issues and the adverse impacts of plastic, more consumers and businesses are turning to sustainable alternatives. The continuous evolution of jute bag making machines, such as the 50% 20 kg models, underscores the potential for innovation in this sector.

As technology advances, we can expect further enhancements in machine capabilities, potentially leading to even lower energy consumption and improved production efficiency. The jute industry is positioned to play a pivotal role in the ongoing transition to sustainable practices, making it a key player in the global effort to reduce environmental impact.

Conclusion

In summary, the 50% 20 kg jute bag making machine exemplifies the intersection of technology and sustainability in modern manufacturing. By embracing these innovations, the jute industry not only enhances its productivity and economic viability but also contributes significantly to addressing pressing environmental issues. As we move towards a more sustainable future, the role of jute bags and the machines that produce them will undoubtedly continue to grow.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025