Woven Bag Cutting and Sewing Equipment for Efficient Fabrication Process

The Evolution and Significance of Woven Bag Cutting and Sewing Machines

Woven bags, known for their durability and versatility, have gained immense popularity in various industries, including agriculture, retail, and construction. The production of these bags involves precise cutting and sewing processes, which are facilitated by specialized machines designed for high efficiency and quality. This article explores the evolution of woven bag cutting and sewing machines, their functionality, and their significance in modern manufacturing.

Historically, woven bags were produced manually, a labor-intensive process that required skilled artisans to cut and sew materials by hand. However, with the advent of technology in the 20th century, the introduction of cutting and sewing machines revolutionized the industry. These machines not only enhanced productivity but also improved the consistency and quality of the final products. As demand for woven bags increased, especially with the shift towards eco-friendly packaging solutions, the need for more advanced and efficient machinery became evident.

Woven bag cutting and sewing machines work synergistically to streamline the production process. The cutting machine utilizes sharp blades and advanced technology to accurately cut the woven fabric into desired dimensions. Precision in cutting is crucial, as any discrepancies can lead to wasted material and increased production costs. Modern cutting machines are equipped with features such as computerized control systems that allow for intricate designs and patterns, reducing human error and enhancing productivity.

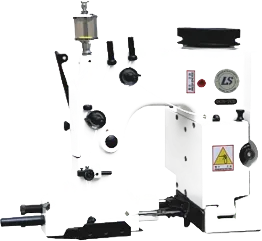

woven bag cutting and sewing machine

Once the fabric is cut, it is fed into the sewing machine, where the seams are stitched together with high-speed efficiency. These machines are designed to handle a variety of thread types and thicknesses, ensuring strong and durable seams that can withstand the rigors of transportation and storage. Furthermore, sewing machines can be equipped with additional features such as automatic thread trimming, adjustable stitch length, and multi-line stitching capabilities, making them adaptable to various production needs.

The significance of woven bag cutting and sewing machines extends beyond mere efficiency; they play a critical role in sustainability efforts. Woven bags are often made from recyclable materials, and their durability allows for multiple uses, reducing the reliance on single-use plastic bags. The automation of the production process also means that less energy is consumed over time, contributing to a lower environmental footprint.

Moreover, the rise of e-commerce and retail businesses has further propelled the demand for woven bags. As companies strive to meet consumer preferences for sustainable packaging, investing in cutting and sewing machines has become essential for maintaining competitiveness in the market. These machines not only ensure high output but also enhance the ability to customize bags according to specific client requirements.

In conclusion, woven bag cutting and sewing machines have transformed the production landscape, resulting in higher efficiency, better quality, and increased sustainability. As industries continue to shift towards eco-friendly practices, the importance of these machines will only grow, solidifying their place as an essential tool in modern manufacturing. Embracing technological advancements in this field will pave the way for innovative solutions that cater to the ever-evolving demands of consumers and businesses alike.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025