Understanding the Mechanisms and Benefits of Sewing Machine Locks for Secure Stitching

The Importance of Locking Mechanisms in Sewing Machines

Sewing machines have transformed the world of textiles, enabling both professional and hobbyist tailors to create intricate designs with remarkable precision and speed. Among the myriad features that enhance these machines' functionality, one of the most critical components is the lock mechanism. Understanding the significance of the sewing machine lock not only helps users appreciate their machines more but also guides them in maintaining and troubleshooting their devices effectively.

Understanding the Lock Mechanism

In sewing machines, the lock mechanism serves an essential role in ensuring that the needle moves harmoniously with the fabric and the presser foot. This mechanism locks the needle in place at crucial moments, allowing for consistent stitching patterns and the seamless execution of complex sewing tasks. Whether you're running a simple stitch or attempting a decorative embroidery design, the reliability of the locking feature is paramount.

However, the concept of lock in sewing machines can also refer to specific types of stitching techniques. For instance, a lock stitch is one of the most prevalent forms of stitches used in sewing. This stitch type is formed by interlacing threads from the needle with the bobbin thread beneath the fabric, providing strength and durability to the seam. The efficiency of the lock stitch is one reason it is favored for joining fabrics in many garment construction projects.

The Mechanics Behind the Lock

At the core of the lock mechanism lies a series of intricate parts, including gears, tensioners, and levers that work in unison to facilitate motion and position. Any issues in these components, such as misalignment or wear and tear, can lead to stitching problems. For example, a malfunction in the lock may result in skipped stitches, uneven tension, or even thread breakdown, leading to frustration for the sewist.

Regular maintenance is essential to ensure these components continue to function effectively. This involves cleaning the machine, oiling the moving parts, and checking for any signs of wear. Additionally, understanding how to thread the machine correctly and adjust the tension is crucial in ensuring the lock mechanism operates smoothly.

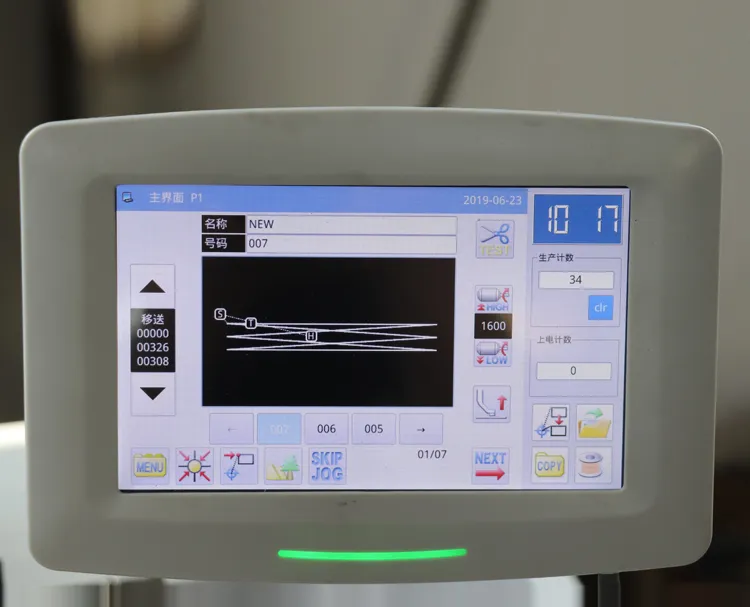

sewing machine lock

Troubleshooting Common Lock Mechanism Issues

Sewing enthusiasts often encounter problems with their sewing machines, many of which stem from the locking mechanism. Some common issues include

1. Skipped Stitches Often caused by improper threading, a dirty machine, or a dull needle. To resolve this, check the threading path, clean the machine thoroughly, and replace the needle if necessary.

2. Uneven Tension This can happen if the tension dial is incorrectly set or if the thread is old and brittle. Adjust the tension settings slowly while testing on scrap fabric until the desired stitch quality is achieved.

3. Thread Breakage A common issue that may arise from using the wrong thread type or a bobbin that is not properly wound. Ensuring compatibility between the thread type and needle size can prevent this problem.

Conclusion

The locking mechanism in sewing machines is fundamental to the quality of stitching, directly influencing the user’s sewing experience. Understanding its function and maintaining its optimal performance can significantly enhance both the efficiency and the results of sewing projects. Whether you are a professional designer or an eager beginner, appreciating the intricacies of your sewing machine's lock will not only empower you to create better work but also extend the lifespan of your beloved machine. By taking the time to troubleshoot and adjust as necessary, sewists can ensure that their machines continue to perform at their best for years to come.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025