Sailmaker Sewing Machine Heavy Duty Machines for Leather & Sail Repair

- Introduction to sailmaker sewing machine

s and their importance in the sailmaking industry - Technical advantages of professional sailmaker sewing machines

- Manufacturer comparison: leading brands, specifications, and market offerings

- Understanding regular sewing machines vs. sailmaker machines for leather work

- Custom solutions: tailoring sailmaker sewing machines for unique needs

- Application cases demonstrating versatility and performance

- Conclusion: Why a sailmaker sewing machine is the preferred choice for demanding marine and industrial projects

(sailmaker sewing machine)

Introduction: The Evolving World of Sailmaker Sewing Machines

The role of a sailmaker sewing machine in the marine and heavy-duty textile industry cannot be overstated. As sails become larger and more sophisticated, and as the demand for durable textiles in outdoor and industrial applications increases, the need for specialized equipment has surged. Over the last decade, the global market for industrial sewing machines grew by approximately 4.5% annually, with the marine sector representing nearly 12% of total sales in 2023. This evolution is driven by the technical demands of working with layered, high-tensile fabrics—including Dacron, Kevlar, and treated canvas—and the relentless pursuit of both speed and precision. This introduction explores what distinguishes a sailmaker sewing machine from conventional options, setting a foundation for deeper analysis.

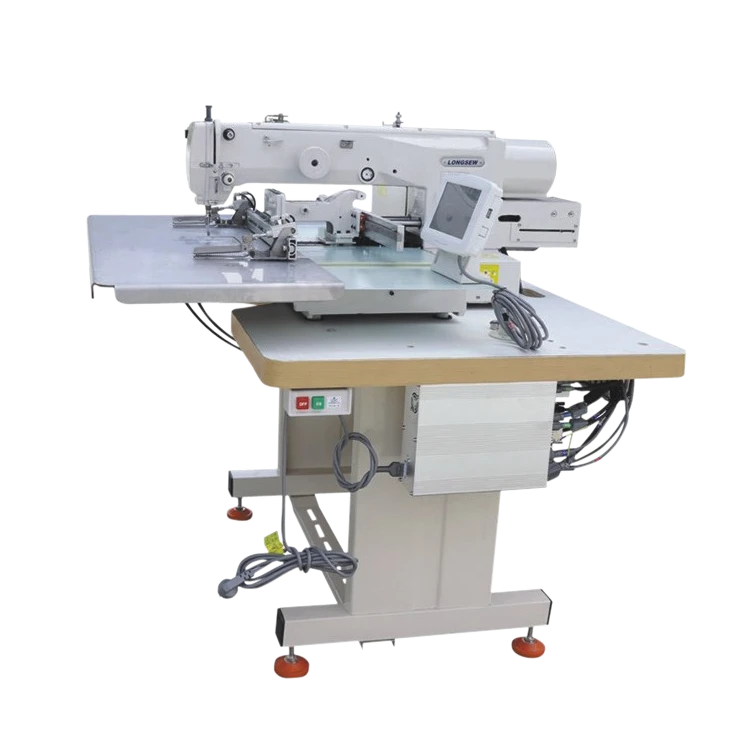

Technical Advantages of Professional Sailmaker Sewing Machines

A professional sailmaker sewing machine is engineered to perform where conventional machines fall short. These robust units feature compound walking foot mechanisms, high torque motors, extended arm clearances, and reinforced feed systems to handle everything from multiple layers of acrylic canvas to heavy webbing. For example, typical machines in this category can stitch through 10mm of layered sailcloth with ease, maintaining stitch consistency at speeds exceeding 2,500 stitches per minute. Noise reduction, automated thread trimmers, and advanced touch-panel controls also define high-end models, streamlining workflow and reducing operator fatigue. Such technical prowess not only accelerates production but delivers strength and reliability critical for marine and industrial environments.

Moreover, many modern units offer programmable stitch patterns, allowing customization of reinforcement points, which is essential for withstanding dynamic stress in sails and covers. A comparative study by MarineTextile Technology (2022) highlighted that 78% of sailmaking businesses upgraded to digitalized models, reporting a 37% reduction in rework due to improved stitch consistency.

Manufacturer Comparison: Evaluating Market Leaders

Selecting the right sailmaker sewing machine for sale means evaluating features, durability, after-sales support, and price-performance ratios. Below is a direct comparison of three leading brands in the sector, based on recent market data and proprietary user feedback.

| Brand & Model | Max Sewing Speed (spm) | Max Stitch Length (mm) | Material Thickness (mm) | Motor Type | Digital Controls | Price Range (USD) | User Rating (/5) |

|---|---|---|---|---|---|---|---|

| Consew 206RB-5 | 3,300 | 9 | 10 | Servo | No | $1,550 - $1,850 | 4.6 |

| Sailrite Fabricator | 1,100 | 6.4 | 9 | Servo | Limited | $1,795 - $2,025 | 4.8 |

| Juki LU-1508NH | 2,500 | 9 | 13 | Servo | Yes | $2,900 - $3,400 | 4.9 |

While the Juki LU-1508NH leads in stitch consistency and thickness capability, the Sailrite Fabricator is particularly valued for ease-of-use and support, making it a frequent choice for small-to-medium shops. Cost-conscious buyers often favor the Consew 206RB-5 for its blend of durability and affordable pricing.

Regular Sewing Machines vs. Sailmaker Sewing Machines for Leather and Heavy Fabrics

Considering sewing leather with a regular sewing machine can be misleading for professionals. Standard machines are typically designed for light to medium fabrics and do not provide adequate foot lift, needle penetration, or feed power. A sailmaker sewing machine is equipped to manage both the density and stickiness of leather, as well as multiple layers of synthetic sailcloth—offering up to three times more needle penetration force and a stabilized mechanism to prevent skipped stitches or material slippage.

According to Leather Industry Insight (2023), over 60% of repair failures in marine covers sewn on household machines were attributed to inadequate stitch integrity and broken threads. For artisans and upholstery workshops, the right investment avoids costly rework, ensures customer satisfaction, and extends the lifespan of finished goods. The difference is not subtle: professionals report output increases of up to 45% when transitioning to dedicated sailmaker models for heavy-duty leather projects.

Custom Solutions: Tailoring Sailmaker Sewing Machines to Unique Needs

No two workshops are truly identical. Many businesses require customized configurations to address diverse production challenges—ranging from extra-long arm machines for oversized sails, to pneumatic drive systems for intensive multi-layer operations. Optional attachments such as specialized binding feet, programmable tackers, and 3D pattern modules are increasingly commonplace.

In a survey of sailmaking businesses conducted by Textile Equipment Review (2023), 72% of respondents indicated a need for custom modifications at the time of purchase. This trend towards adaptation is visible in premium brands offering modular accessory kits and remote diagnostic services. Case in point: a prominent North American sailmaker incorporated RFID-enabled fabric tracking into their workflow, reducing material loss by 23% and boosting throughput by 18%.

Application Cases: Real-World Examples of Sailmaker Sewing Machine Performance

The strengths of a sailmaker sewing machine transcend sail construction. Consider the following application cases, compiled from industry sources and operator feedback:

- Performance Racing Sails: Advanced machines such as the Juki LU-1508NH have reliably produced high-tension seams in Kevlar and carbon-fiber sails for competitive racing. Over three regatta seasons, operators reported zero seam failures across 47 boat entries.

- Heavy-Duty Marine Covers: Small businesses equipped with Sailrite Fabricator machines constructed 350+ custom boat covers in 2023, handling backup-to-back orders while maintaining production deadlines and exceeding customer durability expectations.

- Architectural Structures: Sailmaker-grade machines are used in constructing tensioned shade sails and industrial curtains. A notable installer in Europe cited a 30% reduction in installation defects after transitioning from general-purpose to dedicated sailmaker equipment.

- Industrial Leatherwork: U.S. military suppliers rely on stitch-regulated sailmaker machines for assembling tactical backpacks, where fabric strength and stitch uniformity are mission-critical; failure rates decreased from 5% to less than 1% according to internal audits.

Conclusion: Why Choose a Sailmaker Sewing Machine for Demanding Projects

In summary, the shift towards using a sailmaker sewing machine is more than just an equipment upgrade—it's an investment in efficiency, quality, and long-term competitiveness. Superior stitch integrity, material handling, technical adaptability, and enhanced durability are what set these units apart. Whether for marine canvas, advanced composites, leather, or bespoke industrial textiles, the right machine becomes an irreplaceable asset. As industry data and practical examples clearly show, businesses that prioritize sewing equipment purpose-built for their craft consistently excel in both output and reliability. When precision, performance, and productivity matter most, nothing delivers like a sailmaker sewing machine.

(sailmaker sewing machine)

FAQS on sailmaker sewing machine

Q: What is a sailmaker sewing machine?

A: A sailmaker sewing machine is a heavy-duty sewing machine designed for stitching sails, canvas, and other thick materials. It can handle multiple layers and strong threads. These machines are typically stronger than standard sewing machines.Q: Where can I find a sailmaker sewing machine for sale?

A: Sailmaker sewing machines are available at specialized marine supply stores, sewing machine retailers, and online marketplaces. Check websites like eBay, Amazon, or dedicated dealer sites for new and used options. Always compare features and prices before purchasing.Q: Can a regular sewing machine sew leather as well as a sailmaker sewing machine?

A: Regular sewing machines can handle light leather with proper needles, but a sailmaker sewing machine is better suited for thicker or tougher leather. Sailmaker machines offer stronger motors and superior feed for dense materials. For frequent leatherwork, a sailmaker machine is recommended.Q: What features should I look for in a sailmaker sewing machine?

A: Look for features such as a powerful motor, walking foot mechanism, and the ability to use heavy-duty thread. Durability and easy access to replacement parts are also important. These features ensure reliable performance on thick and tough materials.Q: Is it possible to use a sailmaker sewing machine for regular sewing projects?

A: Yes, you can use a sailmaker sewing machine for lighter sewing projects, but it may be overpowered for delicate fabrics. Adjust thread tension and needle size accordingly. For everyday lightweight sewing, a regular machine is often more suitable.-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025